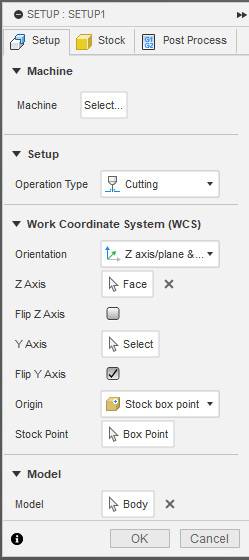

I re-oriented the the coordinates to be on the XY plane

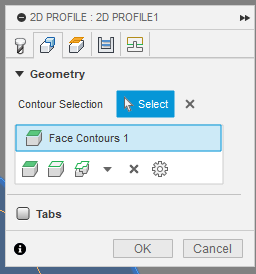

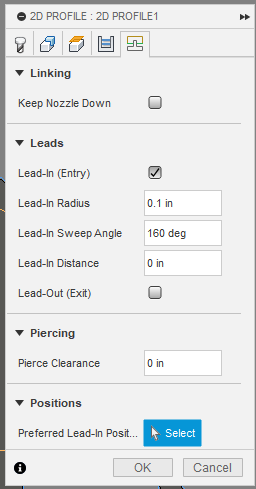

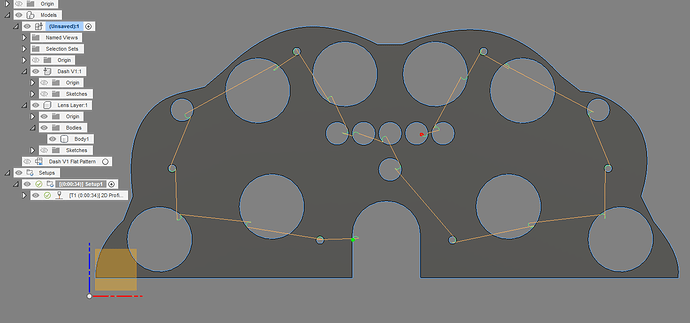

I then set a toolpath, used my tool of 16 gauge steel. It should cut out easily.

Dash V3 v10Chelan.f3d (809.7 KB)

Edit: There are a lot of measurements and alignment with that design. I guess I would consider making a cardboard template first. Replace the torch or attach a sharpie marker to the torch and having the gcode draw it out on the cardboard. There are other threads on this forum that discuss the way to do that.

Hey guys selling some spring loaded sharpie marker holders that work great on the CrossFire and CrossFire PRO with the z-axis upgrade kit. Here is the link to the Etsy page, they are currently only $34.99 (Hand and Machine Torch Versions)

https://shopcpdesign.etsy.com/listing/1607210576

It’s great for testing out your cut path (on cardboard, or on steel and then easily wipe away with acetone, etc…). Also if you favorite the item on Etsy you’ll receive a code for an additional 5% off:

[…

I would like to be able to add markings to my parts. Both for Part number and bend locations. I know I can place these marking digitally in my model but dont mark them as cuts, How do I translate that from my model to my G code? As in have movement of the tool but not have the plasma command fire. I know there is a dry run feature on Fire control but that seems to be on/off and I would prefer not to run 2 different programs of gcode. I will have a pen tool offset from the torch head on my XR.

2 Likes