Hi! It has been a while since I’ve used fusion 360 and have (hopefully) a quick and easy question…

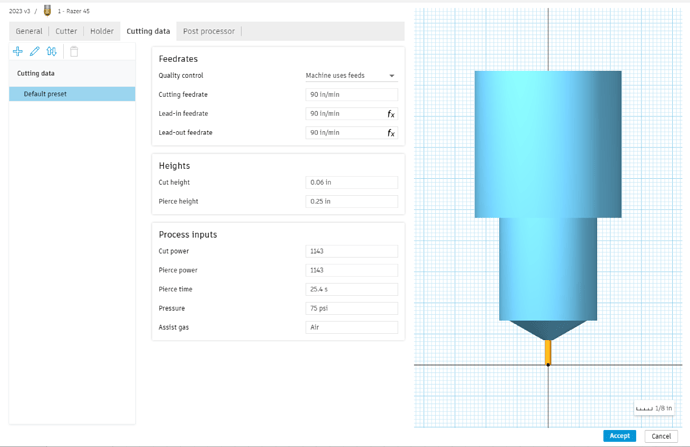

For a 1/8 in sheet metal for a micro part…what should I put in height and process input?

I’ve got a customer that wants me to do 100 of these micro parts… (2 inches high)

Any recommendations on configurations that’ll address heat?

I think you are asking for “pierce height” and that is often 0.15 inches and the cut height is usually around 0.06 inches.

I am not sure what cutter you are using and if you are using FireControl or MACH3.

I have Hypertherm 45XP, FireControl: so I will answer for how I would approach it.

Since your part is pretty small you are not going to want any lead in or lead out but that is settings in the CAM portion. Also remove any values from the “pierce clearance” in CAM.

Your post processor is going to be FireControl.

To control the heat, you can create a toolpath at the end of your cut that “dwells” for perhaps 45 seconds to allow some cooling. If you need help with that I can go into more detail.

You can then use the nest feature in FireControl. This will allow the cut and the dwell time to be activated between each figure that you cut.

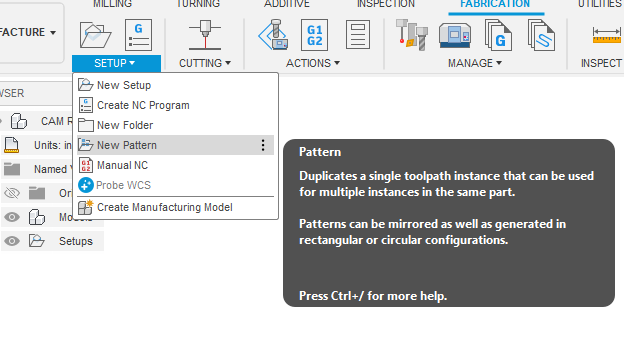

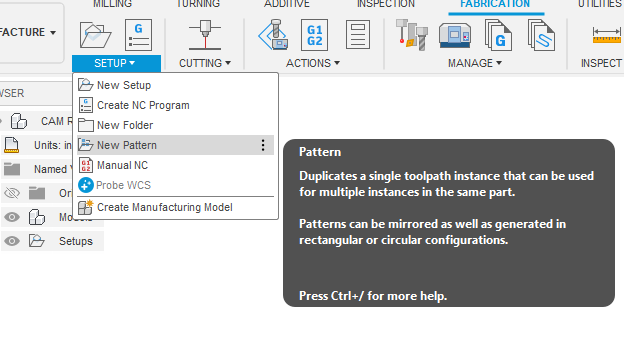

Edit: You can actually setup the “nest” with all the tool paths you created before you go to FireControl:

(Now that I see that it says “Duplicate a single toolpath…” maybe you would need to set up the nest in FireControl.)

2 Likes