Well… if you’re reading this then you are, or were, in the same boat as me. You bought the table and decided to try to learn autocad while waiting for it to be delivered. Maybe like me you looked at all the Langmuir videos… tried to replicate them but had errors come up, missing boxes, and generally got lost and overwhelmed and gave up. I know this because of tables Ive seen for sale with messages like"cant get AC360 selling my table".

Well… you arent alone and if it were not for a couple of very helpful forum members I might have given up too, as even the simplest of operations gave me fits and error codes. As a total newb I thought I would run this thread, chime in as I learn, and what is working for me in the simplest of fashion. The" I wish someone had told me that" evolution that might reduce your frustration.

First, you actually have to make the decision to learn autocad and not some of the others out there. I flailed around for a bit and then realized if I can learn one it will make learning the others much easier. For me it seemed like autocad with all its faults was still where I should focus my efforts. I spent about 20 hours messing around coming to this conclusion. Im merging my other posts into this one for brevity… thank you to those that have already helped me.

This will be an evolving thread as I learn Ill try to post what worked from start to one day cutting a part successfully. When I see all the work others have done Im heartened … if they can do it I can too. Im an experienced weldor and fabricator of 40 plus years. My passion is building unusual old medium duty trucks with modern technology. My table will be utilized to make parts for my projects.

This forum has people who are highly skilled at F360 and they may chime in, which is my hope.

Simple prerequisites… yes a computer with enough power to run autocad F360

(SPECS here

Autodesk shows these requirments

System requirements for Autodesk Fusion 360

WINDOWS BASED

Microsoft Windows Windows 10 (64-bit) Semi-Annual Release Channel

CPU Type x86-based 64-bit processor (e.g. Intel Core i, AMD Ryzen series), 4 cores, 1.7 GHz or greater; 32-bit not supported

ARM-based processors partially supported via Rosetta 2 only - see this post for more information.

Memory 4 GB of RAM (integrated graphics recommend 6 GB or more)

Graphics Card Supported for DirectX 11 or greater

Dedicated GPU with 1 GB or more of VRAM

Integrated graphics with 6 GB or more of RAM

Disk Space 3 GB of storage

Display Resolution 1366 x 768 (1920 x 1080 or greater at 100% scale strongly recommended)

Pointing Device HID-compliant mouse or trackpad, optional Wacom® tablet and 3Dconnexion SpaceMouse® support

Internet 2.5 Mbps or faster download; 500 Kbps or faster upload

Dependencies .NET Framework 4.5, SSL 3.0, TLS 1.2+

Recommended specs for complex modelling and processing

CPU Type 3 GHz or greater, 6 or more cores

Memory 8 GB RAM or greater

Graphics Dedicated GPU with 4 GB or more VRAM, DirectX 12 supported)

Im using an old desktop that barely runs the program and the choices out there are endless… if you have the money then put autocad 2020 best computers and up they’ll pop… looks like about 1200.00 gets you the hotrod computer… but members say they are successful with ones down in the 700.00 range… let your wallet be your guide

Ready set go…

a)Alright if you havent gathered all the Langmuir videos into your collection I suggest you do so… as well as fireshare… which I will experience at some point along with some of you in the future.

b) Download F360 2020 latest updated version… watch the Langmuir video if you dont know how to do it. There are many videos to show you how on the internet. While we are talking about videos remember… its just another person telling you what worked for them. I find a lot of 360 videos go way too fast and skip over many basic functions…Im a visual learner… show me each step and allow me to try it…

If you’ve downloaded current F360 you’ve already discovered that some of the “buttons” Langmuir refers to arent on your “homescreen”… fear not it will get better with a little practice and trying to get some F360 2020 videos… and yes they are popping up now… Ill list what I find

c) The first thing you’ll want to do is set your “preferences”… they are in the drop down menu under your name. (Gosh this gave me fits until I set them) Make sure you set your plane to x,y axis as the default. Set your units of measurement, in my case inches. Set any other preferences you want to your desired needs… and hit ok… and off to your first part.

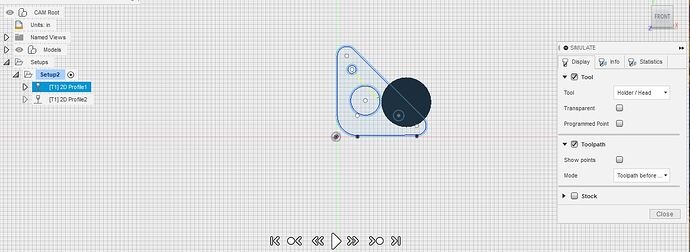

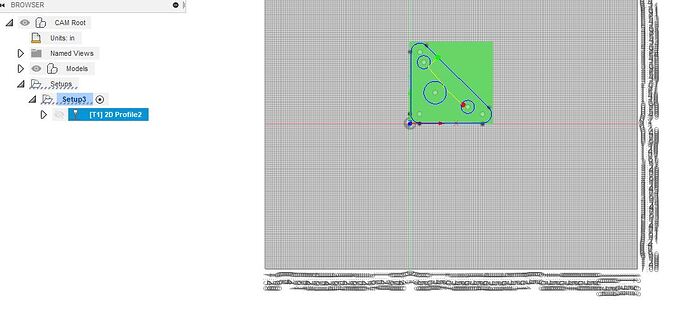

d) Dont you wish we could all just jump to cutting?.. well… not just yet… we have to learn how to design a part first… SVG, DXF all these names are in foreign tongues… just like the commands made by technonerds in autocad…inkscape corel draw, a myriad of other software to learn… ugh… does it have to be so hard… well… not really… if you like start by importing a successful part (file) already drawn by someone else (Langmuir site has many helpful files already created …search the forum for them) into F360 just so you can get it from point A-Z without an error code. Inputting your machine …learning about a tool path… getting the file to manufacture… Langmuir instruction is good at that.

I suggest the below starter videos step by step to design a part from the beginning… note it is a 2020 version so you wont be hunting for non existent buttons or commands (which went into other areas after the November 2020 update). I will try to pick videos where the person speaks clear English, goes slow enough for most of us to understand and try to explain steps not just click through them.

Here’s a good one using INKSCAPE to capture an image and make it into an SVG file to bring into autocad… once you’ve mastered this then the world is your oyster as far as gathered images…

Now to beginning autocad… and designing a part. (This takes you through and into 3d… but all the concepts are the same…or so I believe)

From these two videos I learned how to draw lines, circles, arcs, how to set constraints for sizing and distance, and to extrude to 3d… that last part is not applicable to plasma cutting but was interesting. If you have to repeat these videos many times… don’t worry… I’m right there with you brother. Computers came about in my lifetime… and those of you who grew up on them then this is easy peasey. Me…I grew up on a measuring tape and a feel for design through experience.

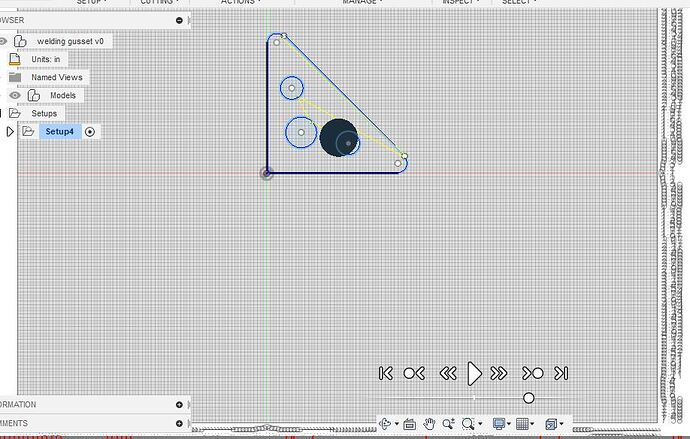

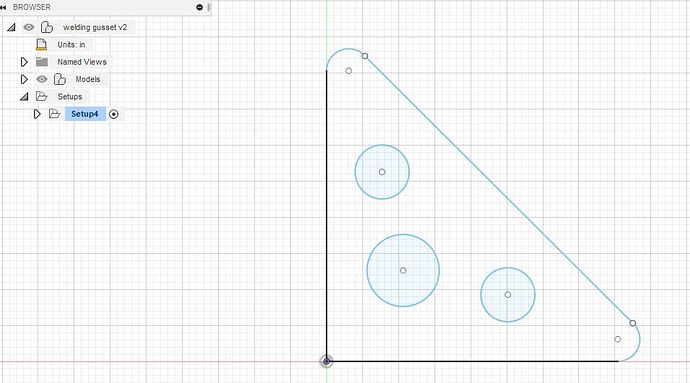

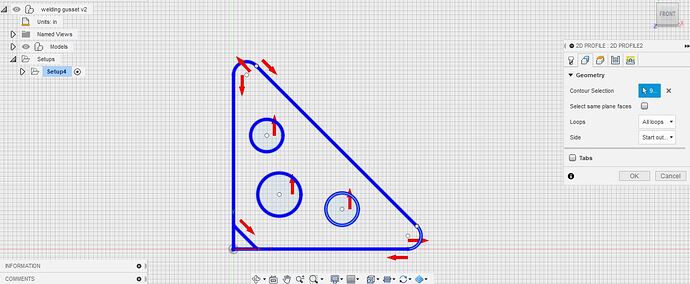

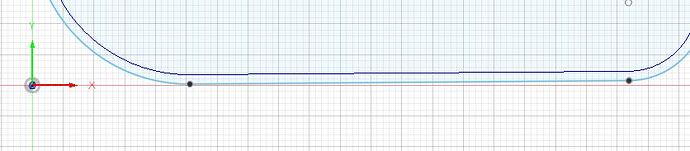

Now I can work on my basic welding gusset… with holes in it for hanging gear or just taking off weight and adding to the cool factor… Ill need to learn how to round the edges… next time

I suggest the KISS principle when first trying to design a part… for me just simple welding gussets will be fine (and there are already successful versions on the site).

That’s it for today… if you’re totally new like me and starting out you just got dog piled with information… come along with me on the journey of learning