Greetings all. Just wanted to introduce myself and start getting to know everyone here. Just got the Crossfire Pro with all the bells and whistles, and the first batch of shipments should be arriving tomorrow, and I feel like a kid on Christmas Eve, I am fired up jazzed, haha!

I’m a middle aged guy that loves jeeps, offroad vehicles of all types, fabrication, welding, and fishing. Early in my career I was in aerospace, did so for about 25 years, working with NASA, Lockheed Martin, Northrop Grumman and other major companies building lots of different things for spacecraft and satellites. Started my career building solar panels, then wound up in Colorado working for a small family owned business building solid state data recorders, flight computers, cables and harnessing and test equipment.

While in Colorado, I got into the off road scene hard, haha…had a Toyota SR-5 that I beat on until it expired, then bought a Cherokee XJ. Of course this led to me wanting to lift it, get bumpers and armor, and I started shopping around and was horrified at some of the prices, so I decided to invest in tools instead, and my love of welding and fabrication was born. Loved it so much, I quit my career in aerospace and pursued welding and fab full time.

Moved out of Colorado and went back to California because my daughter and family was there, and my grandmother was having a rough go, and I wanted to be closer to them all. Worked in a couple of fab shops out there for several years, and after Covid took my mother, me and my pops pooled our resources, sold our properties, and we settled in South Dakota, with a much smaller house, but a MUCH bigger shop!

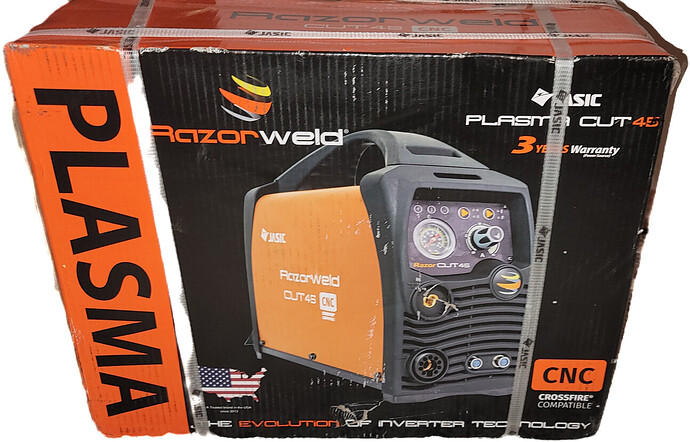

Over the years I have gotten several decent bits of kit, Miller welder, JD2 bender, and lots of fabrication tools. Been wanting a cnc table for a while, so this is the icing on the cake! I’m really excited to get learning, and getting to know everyone. I’m active on CherokeeForum, in fact, I’m admin for the site, so I’m happy there’s a strong forum presence for Langmuir!

Anywho, nice to meet ya!