Happy assembly!! Make sure to stick to the order in the instructions and make sure you understand each step… I made the mistake of jumping ahead on a couple of steps… ended up having to backtrack.

By the way the longhorns on the mower is a nice touch!

That’s my pops’ lawnmower. He’s quite proud of it. I helped him weld up some brackets and a custom exhaust for it, the rest is all him lol

Welcome to the forum.

Thanks. Loving it here so far.

welcome, great stuff so var and very much looking forward to your build process!

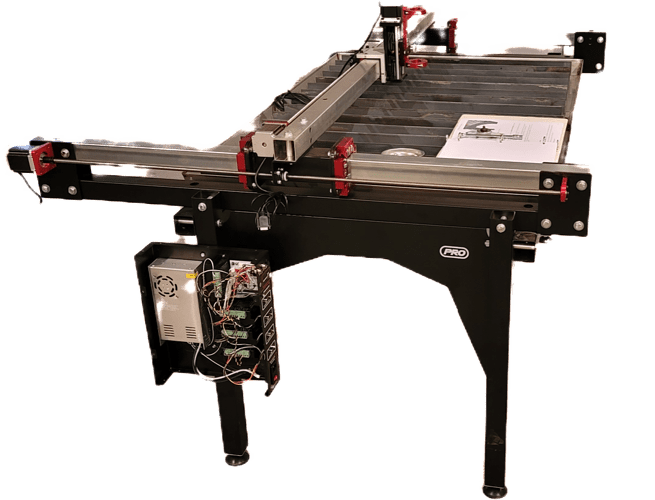

Well, the table is put together, and i got the gussets on yesterday, its been slow, as i only have weekends (with other chores as well) to work on it, haha…and last weekend was a wash due to snow and temps in the low teens…so now I need to get the electronics in and going…next weekend can’t get here fast enough lol

so…looks like a nice clean garage…sorry to see it get all dirty with plasma cutting…lol…

I also guess that you might be moving the table around a bit…were you thinking of putting wheels on the legs?..

DON"T DO IT!

I, myself, found out the hard way that wheels can pull the table out of square…even worse if you try and bolt a shelf between the legs…

the best option I can suggest is to build a rolling platform with leg pockets and if required leveling legs or even the McMaster foot/wheels…

here is a little video I did for the base of my table…

Looks rough as I had to remove the shelf and rolling wheels from the base of mytable as I pushed it out of square by 3/32…

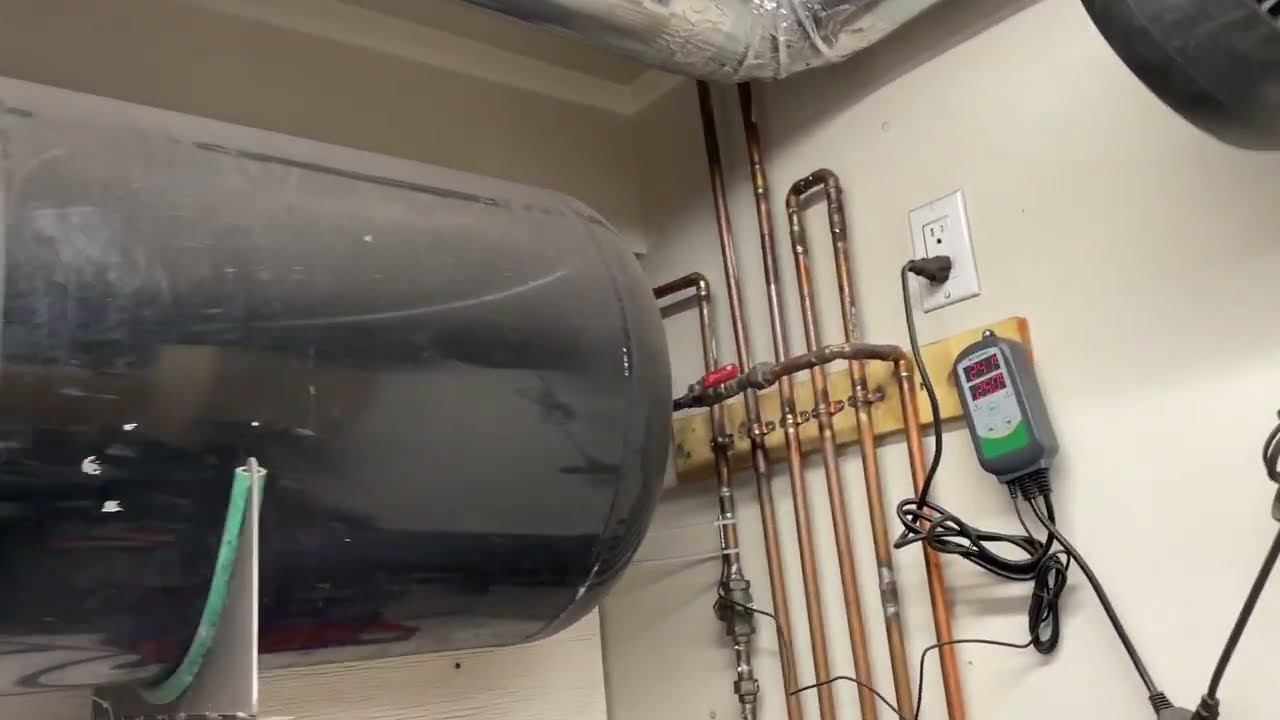

Thanks, yes I’ll be building a rolling platform with heated sump tanks for the water table. Appreciate the heads up

you can see my other videos for other ideas…

did you say heated sump???..really…neverthough of using the table as a hot tub?..neat…lol…

Yes, -20 winters are common here, and my shop isn’t insulated…yet. We’re currently in process of sectioning off 1/4 of the shop and insulating it.

-20F…ahahahahaha…we run around in shorts in that weather here in Ottawa Canada…

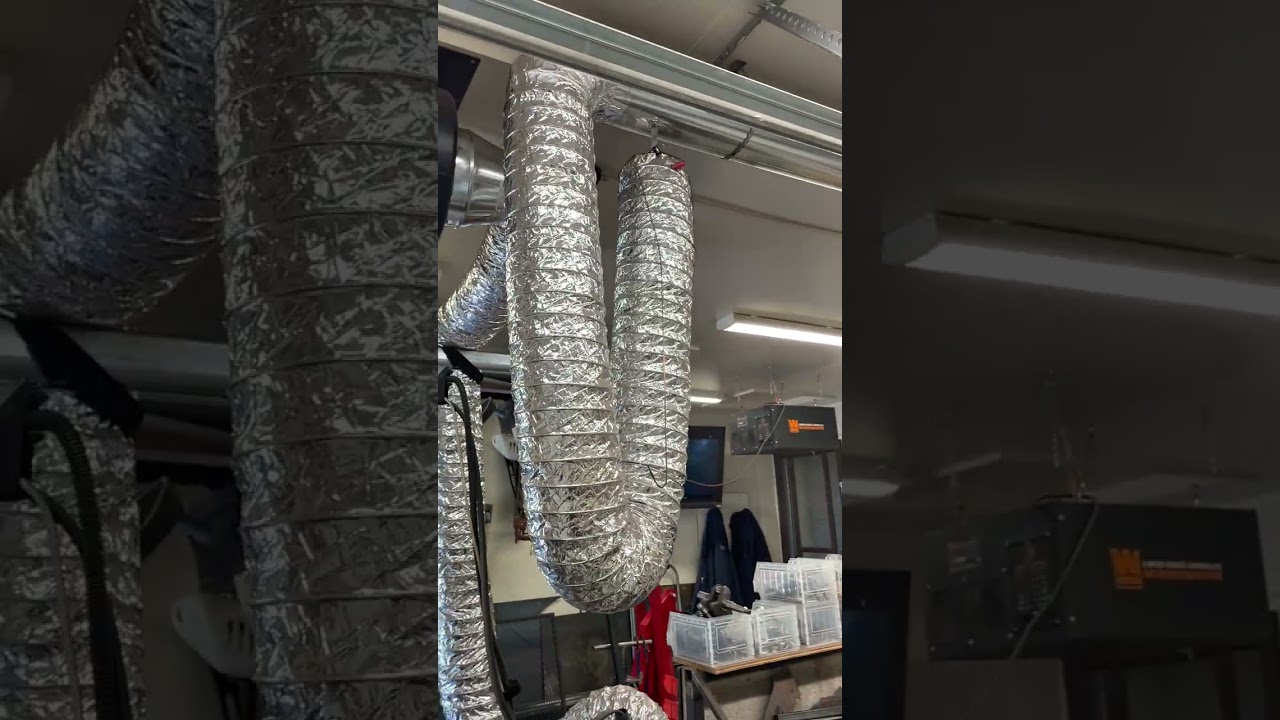

if you enclose a section of the shop to do the plasma…take a look at this ventilation setup I have…saves me hundreds of dollars a year in heating costs…and keeps the air pretty clean…

And I know @TinWhisperer approves this unit…and his approival means the world to me…lol…

Awesome thanks for the links

Thats pretty awesome. Ive been trying to figure out how to exhaust fumes from my shop. So the air exchanger pretty much brings make-up air in while recovering some of the temperature from the exhaust air? Makes sense to have make-up air coming back in so you dont have a negative pressure in your shop causing drafts, and i probably makes the whole system more efficient. Thanks for the video, im going to look into this more.

Torch height control and limit switches next

@TonyH

I can keep my shop easily at a working temp with this…

it just requires cleaning every few weeks…

the core is a plastic heat exchanger I just soak it in cleaners…

You just lost your reason not to go on vacation with the family because your table now became portable:

![]()

What’s a vacation?