Hello everyone,

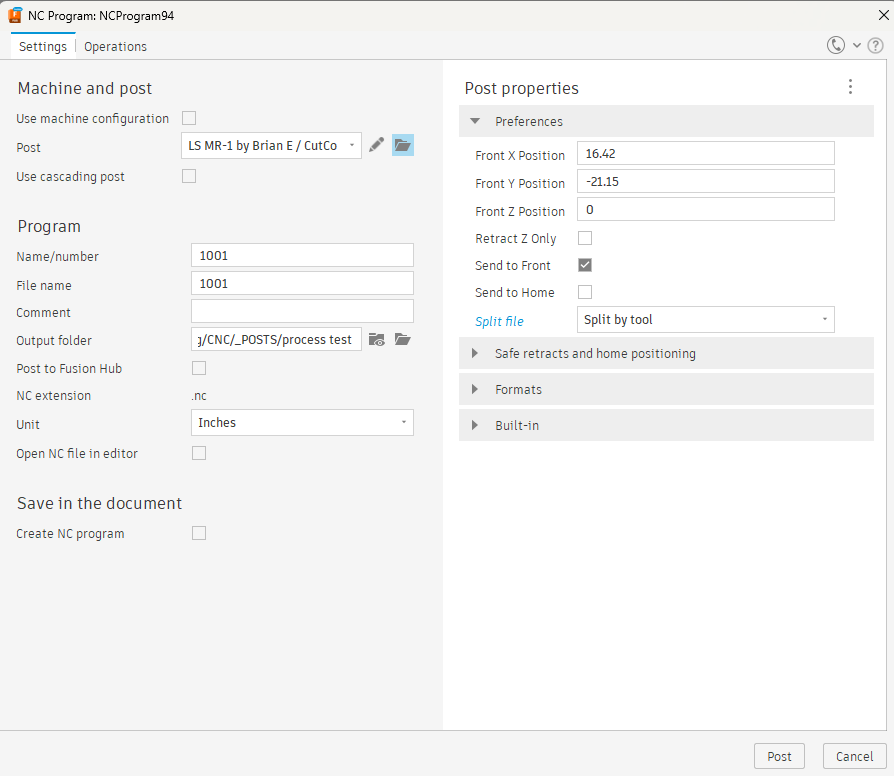

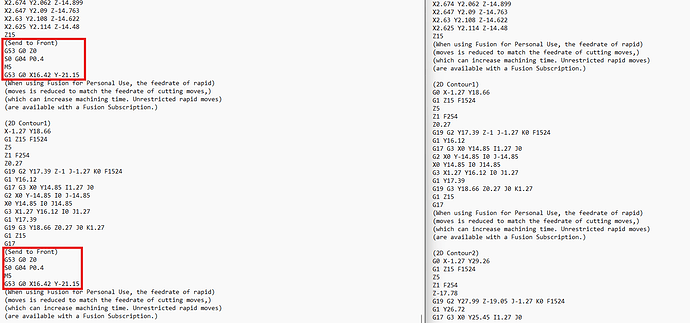

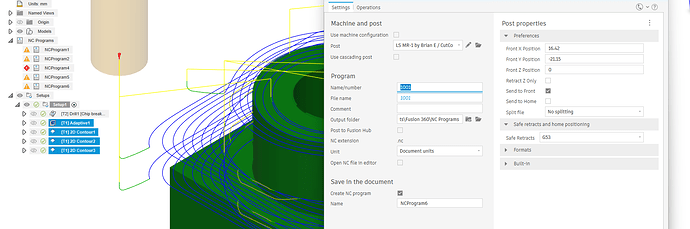

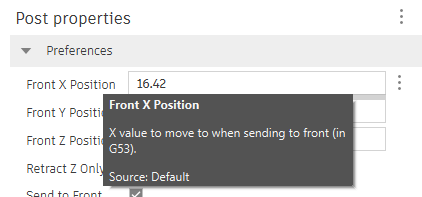

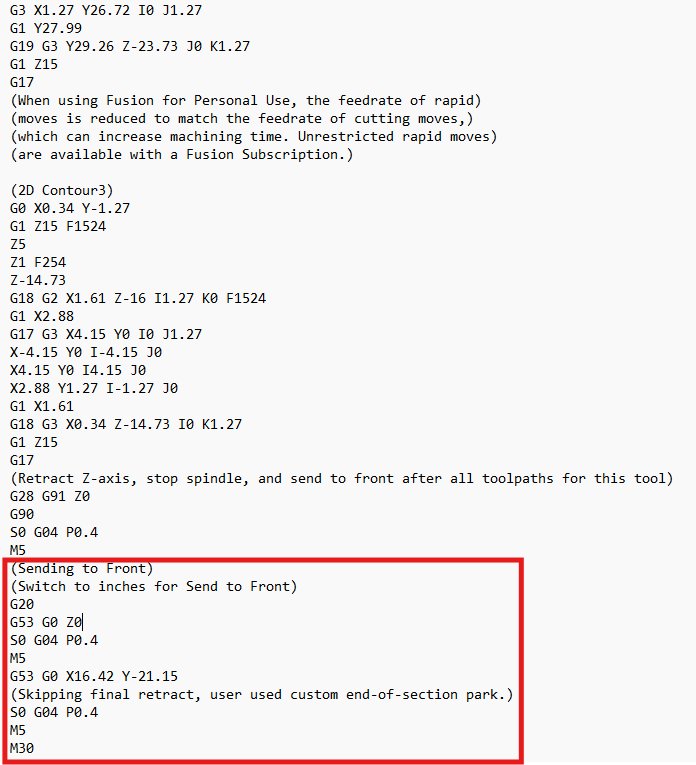

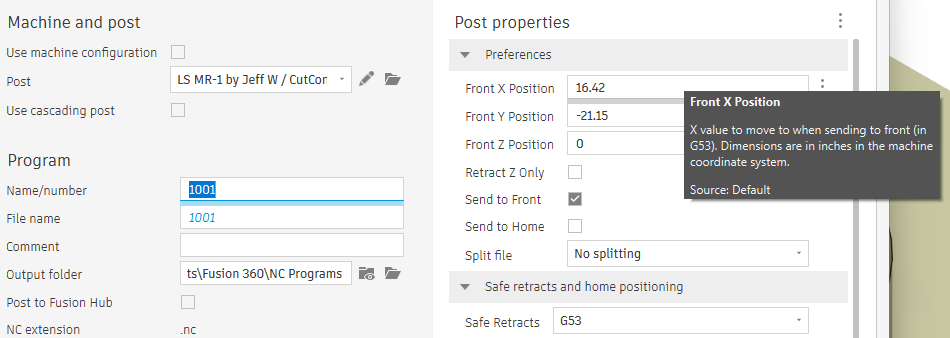

I’ve noticed that when using the supplied Fusion 360 post-processor for the MR-1, the G-code for setting the plane, units, etc., is not always included in the subprograms when using multiple tools with the “Split File” option.

To fix this issue, you can add the following lines to the post-processor script below the call to redirectToFile on line 413:

function onSection() {

// ... existing code ...

if (splitHere) {

// ... existing code ...

redirectToFile(path);

// ADDED: Reset modal variables to ensure G-code outputs in new subprograms

gMotionModal.reset();

gAbsIncModal.reset();

gFeedModeModal.reset();

gPlaneModal.reset();

gUnitModal.reset();

// ... existing code ...

}

// ... existing code ...

}

For those who prefer not to edit it themselves, you can download the file from my GitHub: Modified PostProcessor for Fusion360 for the MR-1 · GitHub