Then I made a blade…

Your lines are going off your table or work space bc the tool path is too large. For example if you were to make that outside cut a an inside cut or a no offset you’ll see your lines come in. Or just nudge over the whole image. Now also make sure the kerf settings are correct (dep on your plasma cutter, check the specs on your consumables and the kerfs). you can also move the whole piece there in sheetcam with the nesting icon (its a 4way arrow) . also you can set the workspace start corner in sheetcam, I always do bottom left. But what is nice about FControl is you can orient the start cut position and also flip the file an any degree you want. Last little note, your lead ins and out are a little large, esp in the eyes. You can tighten all that up so the torch isn’t cutting in thin air bc of all the overlap (once you train your ear to the cutting, you can hear when the torch has too much leads or overcut etc)

I have industrial floor drains in my shop, so this may not be ideal for everyone. I rigged up this pump for a little today bc I over filled my table. It claims to do 5g a min so at 65 gallons would be 13 min to empty. I’ll rig up something neat to keep the pump and proper hoses. But might give some of you another option rather than modifying the water pans. I figured there is no way Im dumping 65 gallons out into buckets that have lift over the bottom braces of table. Pump came from hobo freight, about 60-70$.

And one more articulating screen project. Really simple:

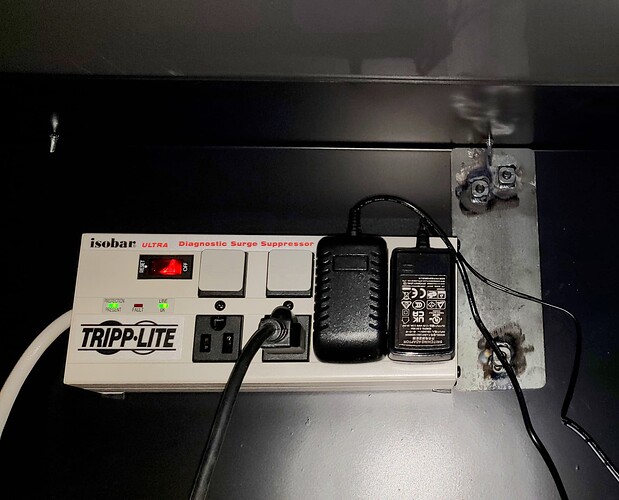

Got tired of all the shop space the fixed mount consumed. Kind of a waist high trip hazard. We fabbed up a steel backing plate with weld nuts and added a power strip to keep things tidy and surge protected. Everything went on nice and straight.

Pretty clean and sturdy. Actual cable management. Not quite as far away from the table (and the splashing) as the OEM but we figure we can make some sort of shielding.

Pretty compact when not in use. A little more cable management and we’ll be good.

where did you pick that mount up would work great for me as well

Amazon. Try Huanuo (but there are at least 1,347 versions of the same thing). Looks better now that we finished the wire management.

The real trick was the backing plate I think (though Langmuir spec’d a pretty robust gauge of sheet metal and it’s a C-channel so maybe not absolutely necessary).

The more we’ve used it the more we like this install. When we have extra long (like 4x10) sheet metal we can run the monitor down low enough it doesn’t get in the way. Like this:

But keep it stowed really compact when not in use so we don’t break anything during material handling of large/heavy plate: