I was able to make my first cuts last night and had some mixed results. First order of business was to make the holes larger in the water tray for some bar sink drains. I was really happy with how well it cut.

Then I moved on to try and cut some 11ga and that’s when I started having issues. Pierces seemed to be OK and everything seemed to be working the way that it should until it came time to cut the perimeter.

The only thing that I can think of is smart voltage showed nominal as 85.9v and the book settings (running powermax 45xp) said 78. I wasn’t able to measure the pierce of cut height, but is it safe to assume actual cut height was too high based on the smart voltage? I did try running one with THC off and it didn’t seem to make a difference (left cut).

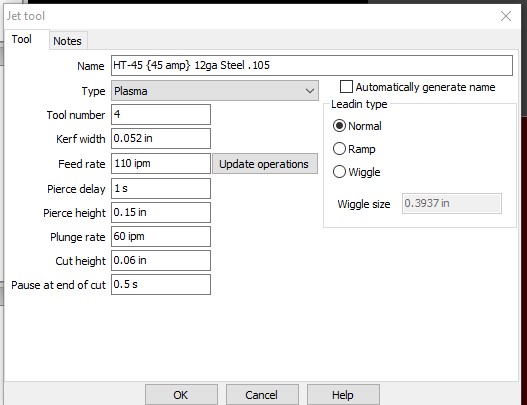

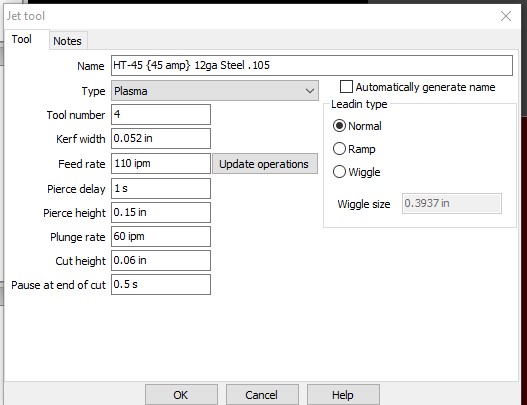

Here’s my sheetcam tool showing my settings.

And a video of firecontrol / video of actual cut.

Few things:

- pierce delay is too long, I know that we need to set it longer because of the two differing ways the delay is measured (Langmuir vs Hypertherm), I’ve been adding .2 which so far has been enough.

- you are getting a fair amount of springback, your sheet is tipping during IHS. Slow down the video at the 19 second mark, watch the end with the clamp. Throw something heavy on that end.

- top dross usually means going too fast. That combined with the fact you are not cutting all the way through would seem to reinforce that.

To check your cut height independent of THC. Turn off your plasma, disable THC, then run, and pause while it’s “cutting” and measure.

If that checks out, try lowering the speed a bit more.

See section on top dross

1 Like

Looking at your pictures, I see one corner is a beautiful cut, this tells me your traveling too fast, the comp slows the torch down for corners and that is where you had a nice cut.

From here I would take my head apart and examine the consumables very closely if not change them. It is possable you have a piece of slag stuck up in there messing up the cone of death.

Then I would cut the speed down to about 60 ipm and go up from there.

The charts are built with perfect power to the plasma cutter, you may not have that especially if the compressor kicks on durring the cut.

One other thing is touch your piece with the flap disk where your work clamp is on it. Always try to put your clamp on a nice clean, raw spot. Maybe you did, I cant tell.

You will get it, these small hiccups make us better later.

2 Likes

After messing around with some 14ga this weekend I decide to try and figure out this plate. Turns out the plate was closer to 3/16" so I set up sheetcam for that using hypertherm 45xp book settings. I checked the consumables and they were fine but I took the finecuts out. Here is the results.

Also knocked out a new taillight housing for a trailer, shelf for the plasma and a mount for the motorguard.

4 Likes