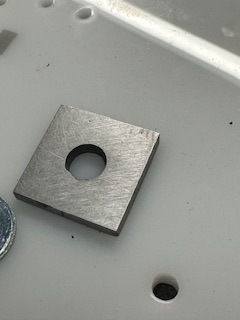

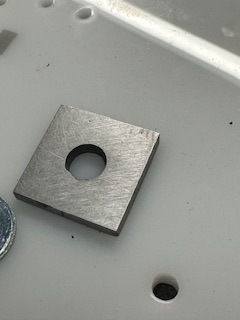

Finally got a cutter in today. Cut 45. First test is exciting. Just made some square with a hole 1x1. It’s amazing how this thing cuts steel like a hot knife in butter. It’s only a few seconds on a belt sander to make this look very clean.

Finally got a cutter in today. Cut 45. First test is exciting. Just made some square with a hole 1x1. It’s amazing how this thing cuts steel like a hot knife in butter. It’s only a few seconds on a belt sander to make this look very clean.

One thing I need to solve this if I walk away from the computer and the screen shuts off and it goes to sleep when I come back and touch the keyboard and wakes back up the machine has reset where the nozzle is to 00. As if you just homed to the last place you left the nozzle.

Go to Windows settings and click on Never Sleep.

All fixed…

Also, look at your power management settings and ensure it’s not on eco. God, I hate that word. ECO means it doesn’t work.

Even if my screen does not shut off, FireControl seems to lose connection with the table and I often need to just close FireControl out and reload the program. Don’t know if that is an idiosyncrasy that only I am having but I have just gotten accustomed to making sure that my program origin and Work zeros are in the right spot before I hit [START].

I am really glad you did this simple test. And, you were even excited with the results. You might have even been AS excited as if you had done a complex design. It is so hard to convince new users that it is the simple pieces of knowing how the design becomes a gcode and then the table follows those instructions. Once you have everything dialed in, not only are are satisfied with the outcome but you understand how you got to that point.

Congratulations.

One thing that bugs me is I want to select parts in an order want to cut. But I want to drag the selection up or down if I want to change the order. It will not let you drag.

Ok easy workaround. Put separate items on its own setup and you can drag setups around

Exactly. Yes, I don’t know how to predict how Fusion decides to cut on a given tool path. SheetCAM allows a numbering system. One thing Fusion lets you decide, and that is not 100%, is the entry for the lead-in. Sometimes it ignores that request as well.

Fusion is sort of buggy to me for this type of machine. I need to look at sheet cam.

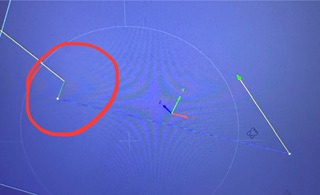

I created a rectangle. Put in a line. New setup. Select the line as open chain and choose center instead of left or right so it will follow the center. Turnoff link( no lead in or out). But no matter what I do there’s this .084” leadin on this straight line. It shows as green and the simulator does this move. Where is this lead in coming from ?

Set your Pierce clearance to zero in the linking tab of the 2d profile menu

Thanks! I thought pierce clearance was a z thing.

Is there a benefit to sheet cam? I kind of see how fusion works with the machine now but interest in opinions

On firecontrol is there a way to enter XY values and press go?

Honestly, I sighed when you wrote you were going to look into SheetCAM. Not because it is an inferior product…far from that. But, you are just a few lessons away from learning how to CAM things in Fusion. Up until now, you have just been getting a drawing thru and not really learning the nuts and bolts of what is happening.

There are lots of us that will help you get going with Fusion. Also lots of people that will help with SheetCAM.

It is just that it took me about 2 months of really striving to learn Fusion 360 and with some key input from Tin, he pulled me out of the gutter and a light switch went off. Now I have the CAM portion of Fusion but I have also continued to learn a massive amount of what Fusion 360 can do in the design spectrum that you won’t get from possibly no other single program. I use the free version and can make it do just about what ever I have a mind to design…except artsy stuff.

The benefit of SheetCAM, is that once your tools are set up and you you know how the menus work it is quick to CAM your design.

But I can say the same thing about Fusion 360. Maybe SheetCAM is a few minutes quicker but I have time. And I have Fusion 360 for designs. If I want to change something in the design and take it to manufacturing immediately, I have now gained back the extra time that SheetCAM would have saved.

But…and here is the big BUT: No one would fault you for going toward SheetCAM.

I know…I am a Libra…can you tell?

I use fusion hours each day for 3d design, only now looking at how to send gcode which is coming together. I’m past the main sticking points. It’s good to know if there are benefits with other methods. I will for sure use fusion just looking for what else there is to take advantage of. I still use bobcad for tons of things for laser and CNC mill for basic things, extremely fast.

Theoretically there is a FireControl post processor for BobCad. Use the search tool to find it. However, if you use SheetCam for your Plasma CAM, then you can use any CAD/drawing tool that can produce SVG or DXF files.

I use fusion and use its CAM for real 3D machining. I use SheetCam for Plasma cutting, however, as that is fundamentally a 2D process and, like I said, I can use virtually any tool as input.

Once you figure out your workflows any one of these software choices would be great to get the job done.

Fusion is many pieces of software jammed together, it’s an elephant to eat.

Enjoy it one piece of time so you don’t choke on it.

I have no doubt that Fusion is only going to get more capable slowly and drowned out everything else over time.

As Tin Man slowly eats the competition… ![]()

I have the mouth for it .

Fusion has “some” ability to follow a cut order.

Preserve order in the Linking tab will have Fusion cut in the order you have selected the geometry. Note - This really only works when you have chains selected, as a Face selection doesn’t have an order, per se.

Re-ordering after selection is another thing altogether. If I needed to change cut order after the fact, I would probably delete portions of the geometry, and create an additional 2D Profile with those selections. The Profiles can be moved within the setup, then the Setup is Post Processed.

Thanks. I saw that before. But I dont like the idea of face selection. I see some guys doing it because it is fastest and simplest. I would always work based on selecting the order of cuts I want. It is simple enough to put cuts on their own setup and or 2d profile, with their own lead in lead out, speeds etc. I would name the final outside cut as “Outer” and it will be last, and it is easy to drag setups up and down. Small holes need their own lead in’s that are different from large outside cuts.