I’m having a few problems with my first cuts that I can’t figure out.

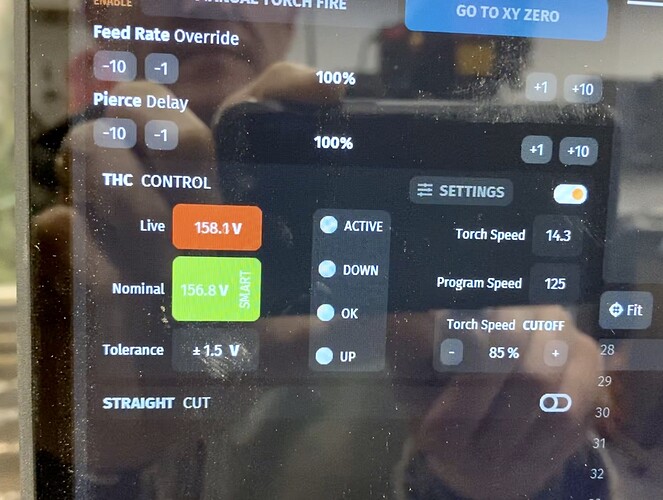

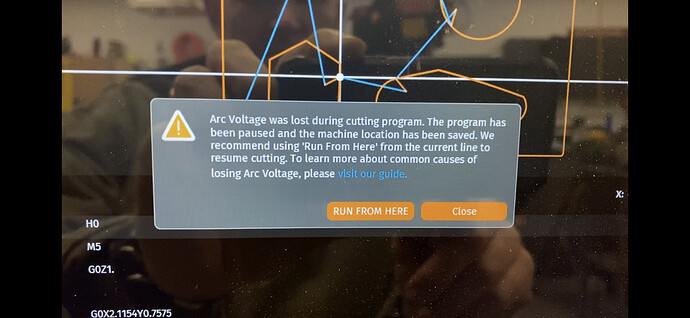

1st. The cutting stops at the end of each loop and gives me “the Arc Voltage was lost during cutting program” error message. I can resume but it stops and the error repeats after every loop.

2nd. When I try to cut with THC turned off in FireControl, The machine starts traveling before the torch fires. The program completes but all the loops are incomplete because of the premature travel.

3rd. The first inside cut of the two files I’ve tried, are super slow, like 13 ipm when the cut speed is set to 125 ipm. The second, third, etc. cut at the programmed speed.

I’m using a Hypertherm Powermax 45 XP with CPC port and the machine is as far away from computer and table as the painfully short output cable allows  The cut files were designed and gcode generated in fusion 360.

The cut files were designed and gcode generated in fusion 360.

Any ideas you guys might have for me to try are greatly appreciated. Thanks

Hi @Blue_Steel glad to see you are up and cutting! The good news is all three of your issues are easily fixable. Please see the responses below.

1st Issue: Hypertherm plasma cutters have a tendency to lose the arc at the end of the cut when using a lead out. We recommend either removing your lead-outs from your program entirely, making your lead-out speed faster (keep lead-in the same as cut speed), or just using smaller lead-out sizes.

2nd Issue: If your machine is moving before the arc can fully penetrate the material then your pierce delay is too short. You need the machine to pause longer after the pierce in order to fully penetrate the material and establish the arc. In addition, if your pierce delay is too short, you can also get an Arc Voltage Lost error from FireControl. I would recommend trying a pierce delay around 0.5-0.7 seconds and seeing if the situation improves. Additionally, you can use the pierce delay override feature to change the pierce delay as well.

3rd Issue: The first loop being slower than the rest is actually a bug in Fusion 360. Another user brought this to our attention over the weekend and we’ve re-written our Post Processor file for Fusion. We are going to test it more tomorrow and then issue this V1.4 release onto our website once approve. You are welcome to try this new Post Processor yourself by downloading here and it should fix your issue: http://assets.langmuirsystems.com/firecontrol/posts/FireControl-v1.4.cps

Let us know if you have anymore questions and good luck!

3 Likes

To build on mike’s suggestions, Langmuir posted a couple of video series on their youtube channel about a week ago that goes over the cad/cam workflows in fusion 360. Being pretty new to fusion CAD, and brand new to fusion CAM, I found their recommendations (crossfire and pro specifically) to be invaluable. I highly recommend putting those videos on a screen while you have fusion 360 up, so you can walk though it all.

For reference, I didn’t have any of the three issues you’ve articulated, Blue_Steel, after following their video guides, and I have the exact same plasma cutter as you do.

1 Like

Langmuir-Mike,

Thanks for the quick reply.

I did see that long lead-outs can cause problems and if you look in the background of the pic I posted of the error message you can see that I had eliminated the lead-out entirely. (although with the first test (F-bomb) I used a super short lead out of .06 with the same result)

I will upload a video I took during the first test (same result on second) showing the movement. I just did a low amperage re-cut of the design to see what was happening. I slowed it down to 1/4 speed on my phone and it looks like the pierce isn’t happening and that the torch fires after travel begins. Pierce delay was set at .04 sec. Interesting to note that with THC turned on the pierce and travel work fine (well, for one loop at a time…)

I will try the new post processor tonight and try again with a new design, and maybe a new computer.

Mike

Your pierce delay is far too short. You need to try something like 0.7 seconds.

I mistyped. My pierce delay was .4 seconds- Hypertherm’s recommended pierce delay for 10 gauge at 45 amps. I’ve cut dozens of pieces of 10 gauge with .4 sec. pierce on the CrossFire OG😜. But I will experiment tonight with longer pierce times.

Thanks.

I installed V1.4 and cut a new test piece. The first loop was even slower than v1.3-about 5 ipm. So I changed back to v1.3 and the first loop was still slow but back at 13 ipm. The remaining loops cut at the programmed speed.

And some good news- I was successful cutting the new design both with THC and THC off. The test piece from yesterday still cut funky with THC on and off with the longer pierce time. So I don’t know if I did something wrong in fusion…

I’ve got pics and video of each step if you’d like to see them. I can DM you if that’s more appropriate.

Thanks.

We released a new version 1.4 (previous was unreleased) of the Fusion post that should resolve this issue. Please download it from our Downloads page.

It looks like toolpaths generated in later versions of Fusion contain a linear move at the start of a cut that moves to the location the previous rapid move (hope this makes sense) and as these are modal values (don’t print if they don’t change) it doesn’t display the line but did set the feedrate output modal such that the next time it was printed (the actual start of the lead-in or loop) it assumes that value was already printed and left it off.

The solution in V1.4 is to reset the modal after the first cutting g-code line is printed. As such, in the event Fusion doesn’t send the extra linear move, you may see an extra F### value on the second line of the first cut loop. These feedrate values should be identical and nothing will change because of it.

TL;DR: The new V1.4 post for Fusion should solve this issue.

We also reduced the secondary IHS sequence to 5 IPM (which should no longer be affecting the first cut as there will now be a feedrate) and will increase the accuracy of the IHS system.

1 Like

I’m having the same problems with ‘Arc Voltage was lost during cutting program’ after each loop and with THC turned off, the torch is moving before piercing after the first cut. I have the Powermax 45 and CPC as above, but I’m using SheetCam. I’ve reduced, speed up, and eliminated my Lead-outs to no avail. Is there an updated Post or a fix for SheetCam? Has anyone found a work around?

Sounds like you have two issues? First, if your torch is moving before piercing, then you need to increase the pierce delay by a suitable amount to ensure that the torch does not move before the pierce happens.

The second issue sounds like you’re getting an arc lost error at the end of the cut?

Also I see that you have the THC turned off? If that’s true then FireControl would not be monitoring at voltage and thus you would not get that error. You can certainly run with the THC off, but be sure to toggle it off on the FireControl screen.

1 Like

Really just one issue. With the THC on, I can cut normally w/ the exception of the Arc lost error after each loop/cut. I can finish the cut but have to go through the restart at position for every cut. The pierce delay is accurate and normal for what I’ve used in the past. The arc lost error is at the end of each cut and the problem I’m looking to solve here. It’s almost the identical issues earlier in this thread.

I did a separate cut without the THC and the torch moves before the pierce delay has completed.

Would you be able to attach your g code file here?

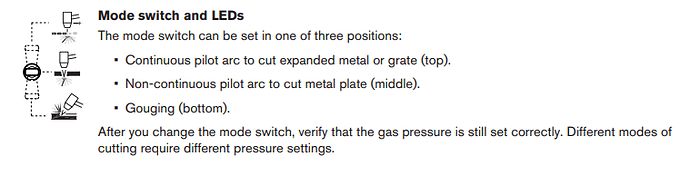

@wvredbeard You might want to try cutting in ‘Continious Pilot Arc’ mode on your Powermax 45. This can be changed by flipping the mode switch on the front of the machine to the top position (see below).

Also, I noticed that the program you attached has a (PS450) value at the end of the program but your actual cut speed is 135 IPM. Did you edit this by any chance? This could be a bug in our Post Processor. If you could attach your .dxf file here we would like to reproduce and try ourselves if possible. I have attached a fixed version of your program for you that has the correct (PS135) value. The reason that this value is important is because the THC monitors real-time speed and turns THC on and off based on a speed threshold.

Old English D.tap (9.1 KB)

I’ll change the mode and see what happens. Thanks.

I did not edit anything.

Is it possible that’s the 300% leadout modification I made in sheetcam?

Old English D.dxf (21.9 KB)

I changed the mode on my plasma to continuous and ran the tap you sent back. I’m still having the exact same problem.

Im also having the same arc lost issue, I did notice in the video I uploaded it seems to do just fine on the first cut and then doesn’t even start piercing before moving on the second try. I had this same cutter and setting from the OG CF and never had pierce delay issues.

Next issue is I added a folding cut line on this version and ran into IHS issues and torch staying on while moving from 1st program to 2nd and giving me a IHS fault

Z-Axis Shield.nc (3.0 KB)

I just looked through your code, and .15 seconds is just not enough time to establish an arc when it’s postflowing. If you fire your Hypertherm with the trigger you’ll see that there is a good 1/2 second delay between when you squeeze it and when it actually fires. You need to compensate for this delay in your pierce delay. I’d recommend just using a generic 1 second delay and then using the pierce delay override in Fire Control to fine tune the pierce delay.

I just looked through your code and there are M5 (torch off) missing which is a known issue with the post processor. We plan on fixing that tomorrow and posting the new version by COB.

Another note- the CrossFire PRO uses a much more robust electromechanical relay as compared to the CrossFire which uses a reed relay. I’m not sure if there is a difference in switching time between the two, but its possible. If you turn your plasma cutter off and hit the manual torch fire button in FireControl, you’ll find that the ‘click’ from the relay is pretty immediate. Compare/contrast this to delay in trigger firing the torch when it’s postflowing.

1 Like

Can you let us know the method that you used for the 300% lead-out modification so that we can fix this issue with our new post update?

As for the arc voltage lost issue, we have fixed this by updating the THC firmware. We are going to sticky a post to the forum today that will provide a guide for how to flash your THC with the latest version of firmware which will fix the Arc Voltage Lost issue.

Thanks!

4 Likes

Under path rules

Rule: On lead out

Feed Rate: 300%

Start Code: none

Distance before: 0in

End Code: none

Let me know if you’d prefer pictures.

![]() The cut files were designed and gcode generated in fusion 360.

The cut files were designed and gcode generated in fusion 360.