So, to preface, i’m not really sure if this is an actual bug, or just a poorly named feature. also I’m trying to type this with my phone and it’s not cooperating, so please excuse any errors and I’ll go back and correct them when I make it to a desktop.

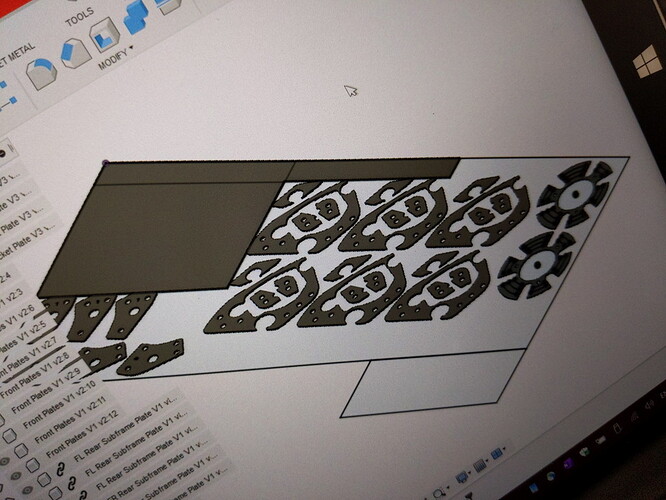

I loaded up a 4x3 sheet with more than a dozen parts to cut and nested as tightly as possible, and since my air compressor is only a 20 gallon running 4.1SCFM at 90 psi, I knew there was a chance I could begin to run low on air.

when the time came to pause the cut, I hit the pause button and the machine stopped instead. and by stop, I mean the machine immediately stopped cutting and just sat there. a pause feature should allow the machine to finish its current cut and then pause after lifting. that way when you resume it will just go to the next touch-off point and begin the next cut.

essentially what I’m seeing is the pause button is more like an emergency pause button, where it’ll stop the machine no matter what and then allow you to resume.

then the stop button also does not seem to function correctly. when you hit the stop button the machine should stop immediately but still allow you to resume. however this is not the case as the stop button functions like a cancel button.

essentially:

when you hit pause, the machine stops.

when you hit stop, the machine cancels.

I’m honestly hoping that this is just a bug and is already in the works to be corrected?

if this is a feature, then I’d like to ask for it to be changed.

there should be four buttons:

start/resume

pause

stop

cancel

for example if you hit stop, the machine should make a note if it was in the middle of a cut or not, then when you hit resume, it should be smart enough to come back down, start the torch, and begin the cut again. (if you hit pause, it should finish the cut first)

I almost lost a $30 piece of steel because of the confusing and inconsistent naming of the pause button. no other machine I’ve ever used (I work as a Quality Engineer in the Auto industry), has ever stopped in the middle of a cut, just because you hit the pause button. luckily, I was able to use Fusion to draw a new cut path and have the machine go back and recut that one specific failure.

if anybody has a workaround for this pause feature, essentially letting me press pause and then the machine will finish the cut and then pause, I would love to know the workaround, because I can’t cut a full sheet without running out of air. what I ended up doing to make it through the rest of the day, was to smack the pause button when the machine was in between cuts, to stop it before it starts the next cut. although this is very hectic and requires a lot of attention, so I can’t keep doing this everyday.

p.s. no, I’m not buying a better air compressor, or a reserve tank, etc, I am way over budget already