Hi all,

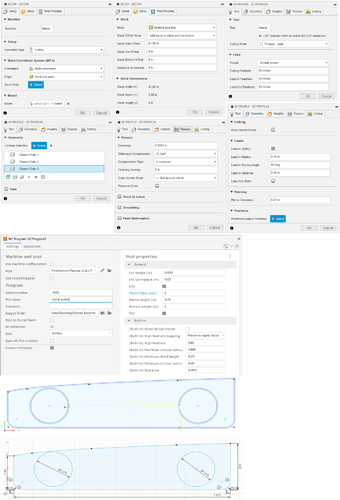

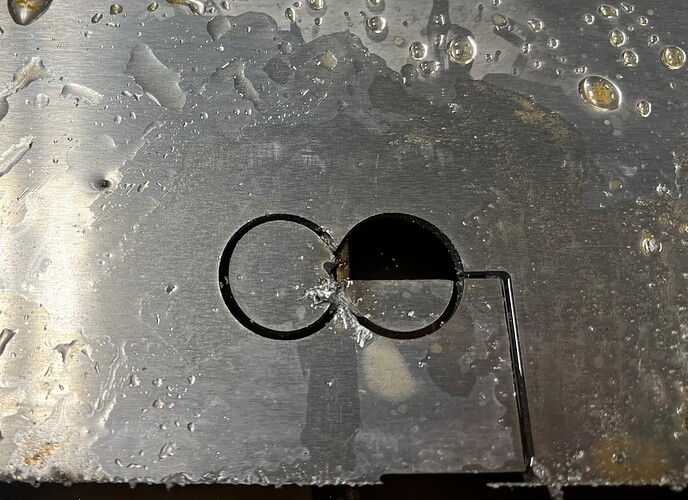

I’m getting a strange issue where the torch will follow the program perfectly while the Dry Run feature is toggled on, when I toggle it off to actually cut the part it no longer follows the program correctly. While it is cutting it will overlap the two circles instead of having them spaced like in the picture below. In Fusion 360 when I click simulate, it follows the cut path perfectly as well. Even the X,Y coordinates in the G-Code seem to be correct for the two circles, yet the Crossfire will overlap them when cut. Any ideas how to fix this issue?

Very interesting…one difference between Dry run and regular run is IHS. I’m wondering if you remove IHS & THC from gcode and just manually set the height it works. This is always great troubleshooting step to understand if one of these might be the issue.

I was confused by a few settings but guessing your showing on thin aluminum but plan on cutting thicker pieces once it works.

Another thing to consider is 60deg lead in/outs and to slow down just a little less than your straight line cut speed. Using 90deg is OK if needed for something small or really tight area but ideally you want less angle to keep torch moving and not such a hard turn.

Welcome to the forum. I want to complement you on such wonderful documentation. I have never seen the detail that you provided.

Now to the issue. FireControl is simply not behaving correctly. It is either some electrical interference because the dry run does not have any energy to contend with or it is corruption of the software. I would suggest a complete un-install of FireControl. Delete the file folder that the program resides and re-install.

I would make a new drawing that is smaller so you won’t use up so much material or you could offset your cut slightly on the same piece of metal on subsequent tries. As soon as you see it is not cutting correct, hit the space bar. That will stop everything.

Do you have the work lead, USB cable from computer to enclosure and/or the torch cable close to either of those cables? Try to reposition them and see what effect that makes. The USB cable should have the ferrite coils on each end.

Watching the video again and almost seems like your running out of travel on IHS and maybe it’s binding up.

2 options -

- Change IHS to 0.5” instead of 1”

- Adjust your torch if hitting top. This would normally give you an error so not sure if this is issue.

Thank you for the reply. I’ve had some issues with electrical interference in the past and have since switched to only cutting with my laptop on battery power with the clamp directly on the work piece and now get a consistent 116ish V on my THC.

I have Windows installed on a partition of my Macbook Pro with Bootcamp and have been running FireControl with that. I tried your suggestion and switched to the Mac OS partition today and installed a fresh version of FireControl and got the same result.

Next I tried making a basic model on a fresh install of Fusion 360 on a desktop computer inside my house with a small rectangle and 2 circles inside. Sent the .NC file to my laptop and ended up offsetting everything all weird again.

I’m beginning to wonder if maybe this is a hardware issue inside the Crossfire enclosure?

I will try a test cut with THC and IHS turned off and see if it at least follows the program.

If the dry run works flawlessly, it is not likely a FireControl issue. FireControl is interpretting the gcode accurately during the dry run. Adding the torch/z-axis movement would not make FireControl lose track of where it was on the table.

Think back on any changes you may have made recently. I am assuming it was working correctly.

Unfortunately, I think you have some electrical interference issues again.

I tried DonP’s suggestion and did a test with both IHS and THC turned off, manually set the height and to my surprise I got the correct cut.

I moved the torch in the holder to get more Z axis travel because it does almost sound like it is binding in the video and now have over 2"s of available travel. Tried cutting the part again with THC and IHS enabled and it went back to an incorrect cut. It still makes a slightly weird noise when transitioning between circles even though it now has plenty of Z axis travel. I know I’m not having binding issues because I can jog the table around at any speed in any direction without issue as well as the dry run with no binding issues.

Next I tried leaving IHS on but THC off and it also made the incorrect cut. Now I’m not sure if I have a setting incorrect in CAM or if there is something wrong with my hardware. I’m pretty novice still to all this.

You might try lubricating all of the screws: x, y and z. I recommend silicone spray but be careful with the z-axis to keep it off the IHS electrical contacts.

I still don’t think that would make such a radical movement pattern. Electrical interference can be intermittent so you might be going down some rabbit holes.

Have you raised the torch to around the IHS setting of 1” and tried moving the torch. Glad we got you cutting again.

Just fyi…You can shut off your torch now and do regular runs so your not ruining stainless or metal. You might need to turn off THC but you want to leave IHS enabled so you can see what is going on.

Hopefully the problem is solved. I was able to cut my test piece twice with both IHS and THC enabled and got the correct cut. I cleaned the Z axis screw, rails and then took a Q-tip and cleaned the lifter switch contact and brass screw contact for the IHS and they were both dirty.

I’m going to move the plasma cutter as far from the enclosure as I can get it tomorrow as well. Hopefully all these issues are behind me.

I appreciate the help Don and Jim!