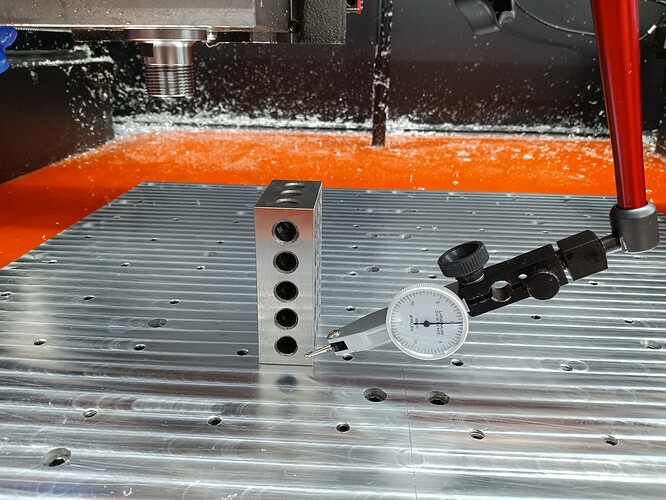

Did my alignment test on the z tonight. I’m out 2½ thousandth. I’d like to get it a little better than that. According to the calculator and my test cards I needed three shims in the lower position. Question is do I take it apart and pull two of them out or would you just add two to the upper locations?

There’s not much to take apart. Just take out the three 5/16 cap screws, slide the lower carriage over, remove the shims, and then slide it back into position. Should just take a few minutes.

OK sounds good thanks! Never thought about sliding the bearings over😂. Must be tired!

Hello, I’m in the process of adjusting my z-axis, but whether I add shims or take shims away I see very little change on my dial indicator. Currently there is approx .005" misalignment.

Any advice would be appreciated.

I had a similar issue with adjusting the nod. When assembling, the LS shim calculator called for 3 shims on the bottom bearing blocks. After a few projects, I decided to fine tune the nod and tilt. The nod was leaning back by a few thou so I added shim(s) to the top bearing blocks to try and even it out, I was avoiding pulling the shims from the bottom, but I added up to a stack of 3 shims with almost no change.

I ended up pulling all the shims from the bottom and still had a lean back on the nod. I examined the shims from the bottom and there were screw indentations on the inboard upper corner of each shim stack. These lined up with the bottom screws to the linear Z-Axis rails. Apparently the screws were too long and impacting the bottom bearing blocks. I ended up removing the screws and grinding them down a bit.

Even after all that, the nod was much better, but still had a slight lean back. I had to put a couple of shims on the upper bearing blocks. I think my deviation tag(s) may have been mismarked as negative instead of positive.

Not sure of your exact issue, but that was my experience. Sorry for the long story.

Hello, thanks for the response. Yes, I noticed the indention in the shim as well. I will take a look. Hopefully that will resolve my issue, because currently nothing changes when I add or remove shims. ![]()

Those super fine shims for the Z axis were pretty much useless for me. I used leftover Y Axis shims. One course, one fine, and one or two of the ultra fine Z axis shims got me to 0.000 from 0.011.

One Y axis shim can be cut into two Z axis shims with tin snips.

Thank so much for the tip. Sounds like a great idea. Will give this a try as well.