What are all of your favorite tools that compliment your cnc plasma table? Im thinking about buying more tools to make more use of my table snd was wondering the order of importance/value that you guys put on different tools that compliment your setup. Right now im debating between a bender and a cement mixer/ parts tumbler setup, but im open to ideas and interested in everyones take on this subject.

I expect answers to vary greatly, all based on one’s needs.

For me, two MIG welders, one TIG welder, two plasma cutters, oxyfuel setup, a small press brake, some fixture tables, and a ton of clamps.

I currently have a decent selection, including an xmt304 with mig,tig, and stick setup, crossfire pro with powermax 45xp, basic shop equipment like table, vice, 20 ton press, vertical and horizontal bandsaws, all the normal stuff like clamps grinders and what not. I have a few areas that could be improved though, such as i have a powder coating gun but need a better oven. I was thinking about the swag press breaks for bending, but a box and pan break might be better. At work i built a slip roll, would be nice at home. A tumble/ blasting setup… the list goes on. Im just trying to see what people get the most value out of.

You really need some way to bend metal because not everything will be flat. I suppose you could be a great welder and that would suffice; but, they say “nothing is stronger than the parent material”.

Cleaning up the material after cutting is a bit more complicated since no one process solves all problems:

- Acid bath (vinegar) will remove mill-scale and some dross

- FireBall slag removal tool is very helpful and quick (less than $100)

- Grinder and a plethora of discs to choose from

- Burnishing tool

- Magnetic vice (I would like one of these but really only works with steel)

- Sand blaster

- Tumbler/vibrator cleaner (like you say)

Then there is the painting process:

- Spray paint

- Powder coating

The list will keep growing

Personally, I didn’t care for the Swag Off Road kit on my old 20 ton press brake.

This is what I use most.

The list never stops. It is a disease. The length of the list solely depends on your bank account.

I agree that the question is difficult to answer since it’s so dependent on one’s current needs.

In your case it sounds like a bender is the best choice.

You can’t bend parts with a cement mixer, but you can clean up parts using various methods.

“The list never stops. It is a disease. The length of the list solely depends on your bank account.”

+1 ![]()

Not that I ever get dross ![]() … but since several of you are talking dross scrapers, I use a brick chisel from Lowes. One trick I’ve learned is that if you gently strike at about a 15-25 (just not quite 0) degree angle it often pops off easier than being scraped. You don’t want to hit too hard and leave witness marks on you piece. If it’s going to pop, it only takes a gentle strike.

… but since several of you are talking dross scrapers, I use a brick chisel from Lowes. One trick I’ve learned is that if you gently strike at about a 15-25 (just not quite 0) degree angle it often pops off easier than being scraped. You don’t want to hit too hard and leave witness marks on you piece. If it’s going to pop, it only takes a gentle strike.

It’s chipping vs scraping. I’ve had some that refuses to scrape off and I just lightly chip it from the edge and it pops right off. Sometimes fairly long pieces come off by striking in just that one spot.

Demo of the angle/chipping technique:

Along with Bret’s idea of striking the area, this device will be able to access tight areas after welding but will leave “witness” marks.

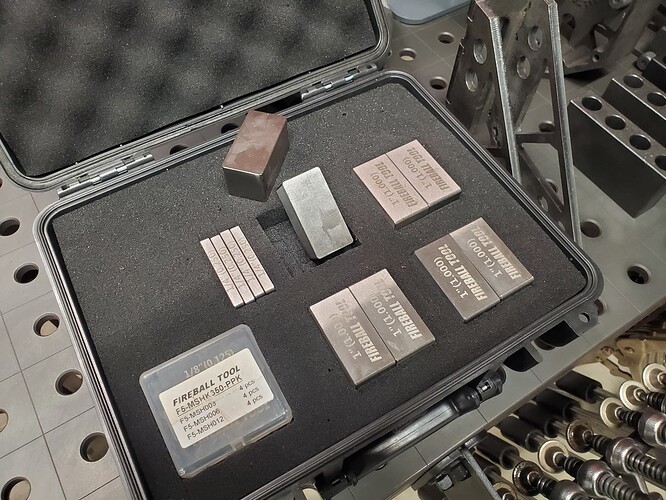

One tool I only recently bought into last year are shims.

I bought the small shim kit with 1/32", 1/16", and 1/8" shims and have used them quite a bit. In fact I think one of my shims needs replacing because it got burned through.

Earlier this year I added the 1" blocks and use them all the time only to recently add 1/4" shims.

I’ll need to add some 1/2" shims to complete my own little set.

I have one of these. Thats a good idea, i usually use a piece of flat stock with a sharp edge and slide it from the center of the piece out. It works really well on larger pieces, we do it at work all the time on structural steel. The reason i was thinking about a cement mixer is I’ve been making alot of motorcycle brackets lately and they are small and tedious to remove the dross. I think ill give the chisel a try. ![]()

Key stock works pretty well for this application as well. Do you mainly use the shims for fixtures?

I am a welder, but bending is much more efficient.

My favorite addition/addiction to my table was this magnetic vise.

TECHTONGDA 12in x 12in Fine Pole Magnetic Chuck CNC Permanent Magnetic Chuck Powerful Sealed Chuck w/ ≥200 N/cm² Magnetic Force Amazon.com

Pretty much

Whether something needed to be offset a specific amount (welding up a frame knowing material will be placed on the face) or something similar

I used to rely on scraps I had in my scrap box, but the odd shapes/sizes of those cutouts made the whole thing unappealing since I’d have my scrap picked up once a month

I bought my shim pack and have used them a lot ever since

You know I really want one of those magnetic vices. ![]() (that is for envy)

(that is for envy)

Only thing better than posting about a useful tool is adding a link to said tool; going to have to order it one of these days ![]()

If you are talking about the magnetic vise. It is amazing. You lock down a piece of steel, and it is not moving. Period. I use a burnisher barrel mounted on a DeWalt 7-inch grinder. Bam, you are finished. The darn thing weighs 100lbs easy.

I mounted it on an old radar arch from a scraped boat. It sits at about waist level. It is so powerful that my fireball slag tool will stand straight up on its end.

I felt the same way, not because it didn’t work, but because it was so dang time consuming if you wanted to make multiple bends on multiple parts and have them accurate.