Yep. I believe Erik supplied that in another thread and may have directed it toward me! After all, it IS all about me (in my mind)! ![]()

![]()

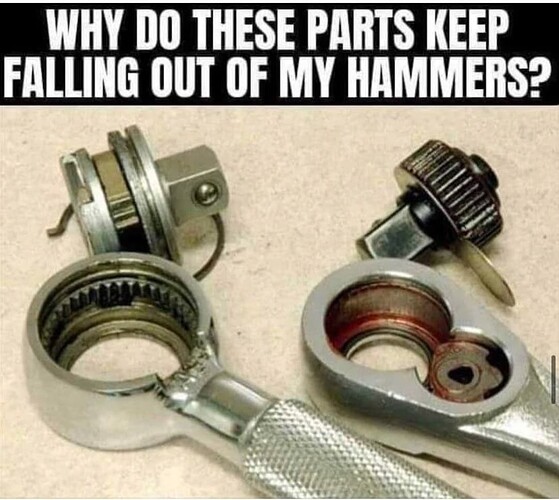

@holla2040 I am president of the grinder club. If you want to join, I can send you a membership card.

I have been doing allot of research on how to improve my welding… I am hoping to get to a point I don’t have to use the grinder quite so much. ![]()

![]()

I am mostly self-taught working on farm equipment when I was a kid. My dad used a 200 acre hobby farm to raise his kids.

@72Pony send me some up close pictures and specs on you equipment. No judgement or laughter. We will get you through grinders anonymous quickly…

No joke if you have the basics a short time with a seasoned Welder would make a world of difference.

I have a Miller 252, Primweld Tig 225x, Miller 211 inherited from my FIL and a old stick welder also from my FIL… not sure what it is, I’ll have to get a pic.

The 211 has the auto wire feed speed and I don’t like it much. I am sure I am doing something wrong, but it starts out super slow then speeds up and melts the wire into the tip often. Now that I have My 252 in my FIL’s shop I don’t really have a reason to use the 211… other than it is a dual voltage machine and it is smaller and more portable than my 252.

I tried doing a little tig welding Saturday but failed miserably. I think I was getting impatient waiting for the pre flow and pushing down too much on the pedal. the tungsten kept melting into a ball. This didn’t happen to me last time I tried with the same settings and same material… I just didn’t have enough time to really get into it(short hall pass from the wife) so I just went back to the MIG welder. Ill try the TIG again when I have more time.

I am the last person who should give advice on wire feed welding but it could be the feed wheel is worn and needs to be replaced. Mine is especially susceptible to wire feed problems if there is just too tight of a turn in the torch line.

I am with you here… always looking to see what the lead looks like alignment wise before I start.

I might cut out one of these for the outside wall of my garage:

I smile every time I see this one.

Those Superstition cut off discs are Wonderful.

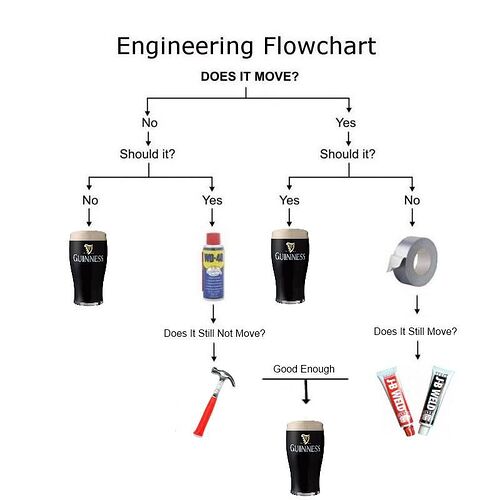

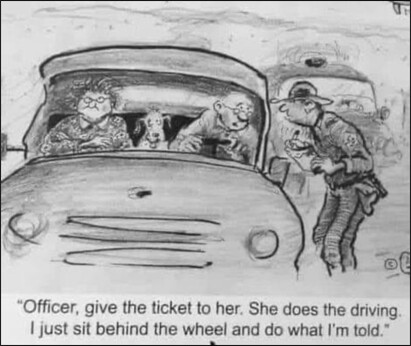

Wife just sent this to me!

That was funny! Thanks for posting

A diesel mechanic flow chart will have one more leg to it. If it still doesn’t move get a bigger hammer. So says a joke I have always heard.

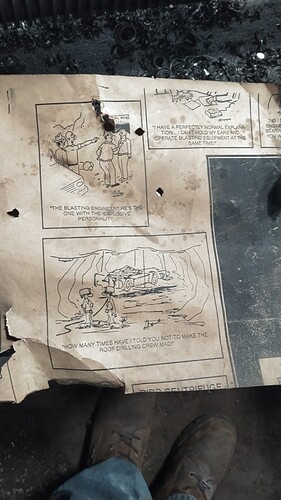

My previous employer had this on the office wall. I always thought it was kinda funny. Maybe just a coal miner’s thing though.