Hey everybody, just signed up here! My name is Brian and i just received my plasma cutter a couple days ago and it looks like the cnc table and water table are being shipped. I will be receiving everything in the next couple weeks! I fabricate security doors mostly here in Vegas and usually source custom plasma cut pieces through our supplier but saw this sweet set up a few months back and said GOT TO HAVE IT! I am pretty excited and have started doing some research. Before posting up my questions i do try and read through topics to get ideas and learn the steps to set up my table! Currently working on running a dedicated 50 Amp 230V plug for the table. I believe we are running an 8g wire to power it up, well my buddy who is an electrician. Im just pointing out were i want it and pulling the wires for him, haha. I believe 8g will be sufficient. Will the table need its own dedicated 120V plug or will i be able to run off of one i currently have that power a refrigerator? Thanks in advance guys!

50A for your Plasma cutter is definitely sufficient. The table electronics doesn’t need much, probably around 400W, so yes, you can share that 125V line without a problem - your beer will remain chilled!

Exactly Tom!  Thanks for the input … currently working on what program we will be using with a buddy. He does house plans so would like to use something that he is familiar with just in case i have questions. I plan to cut a lot of 22g steel so am also looking for some tips and tricks for a thinner metal. Any input would be awesome!

Thanks for the input … currently working on what program we will be using with a buddy. He does house plans so would like to use something that he is familiar with just in case i have questions. I plan to cut a lot of 22g steel so am also looking for some tips and tricks for a thinner metal. Any input would be awesome!

Any 2D CAD program should work for you so what he uses could be ok (if it can do something other than Feet and Fractional inches)

There may be more optimum CAD programs, which you can learn over time, but, IMO, having someone nearby who can help you is probably the most important feature!

The key thing is to be able to export DXF, SVG, or HPGL files. All of these can be imported to SheetCam, which is my recommended CAM program (used to convert drawing files to G-Code files for the Table Controller).

Brian,

welcome to the group you’re gonna love your crossfire I’ve been using one for the last year and I would be lost without it.

Just watch all the videos on YouTube and with the help of this group you will not have a problem because when you do have a problem somebody on this group has the answer.

Learning curve is a little steep in the beginning and you might make a lot of scrap but it’ll be worth it.

I have used Kubotek (Cadkey) for the last 25 years so Cad is not a problem for me but all you need is a simple CAD program that can make DXF files.

I use sheet cam to convert the DXF to G code

Then Mach 3 to run crossfire

Ok thanks both of you! I forwarded this info to my buddy! Yes definitely have been watching all the youtube vids i can find on this and keep watching them over just to try and let it sink in. See you guys around!

Brian

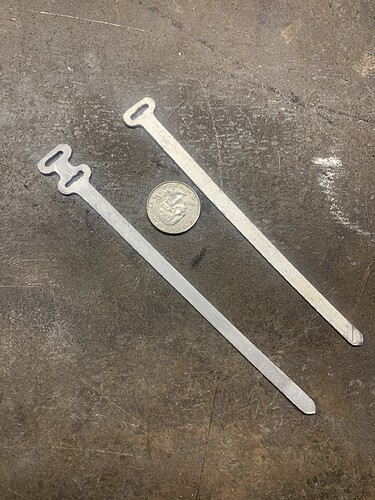

here’s a couple pictures of projects I’ve worked on and I’m still learning.

first one is cable straps made of .05 5052 aluminum

And the next one is a tubing bender made out of 3/8 plate

Tom

Nice Tom! Those straps man, it will be fun seeing how small i will be able to go into the details.

OMG!  Finally assembled my crossfire! Super stoked until i started looking into everything that comes after assembly. Downloaded fusion 360 with the year subscription for free but its pretty overwhelming. I will be seeing my buddy tomorrow so we will have about an hour to work which obviously wont be much. I will most likely be on my own so any more info you Toms/guys can provide is really appreciated. I have watched tons of YouTube the last 2 days having now more question than answers

Finally assembled my crossfire! Super stoked until i started looking into everything that comes after assembly. Downloaded fusion 360 with the year subscription for free but its pretty overwhelming. I will be seeing my buddy tomorrow so we will have about an hour to work which obviously wont be much. I will most likely be on my own so any more info you Toms/guys can provide is really appreciated. I have watched tons of YouTube the last 2 days having now more question than answers  you mentioned steep learning curve and that you did not lie about! I may be starting a new thread for additional guidance in this process.

you mentioned steep learning curve and that you did not lie about! I may be starting a new thread for additional guidance in this process.

Glad to hear you got your machine together like I said before you’re gonna love it

I get my DFX files from a cad program that I’ve been using for 25 years so there’s no problem with that for me. then I use sheet cam which I love it’s so simple you import the DFX file and boom it creates a G code well maybe not that simple but definitely easy.

Just to see if I could do it I was in Harbor freight and I saw a little wooden model or puzzle of a butterfly so I brought it. I scanned it on the office scanner printer the diagram on the back of the box imported it into ink scape made a DFX file imported it into my CAD program cleaned it up then went to sheet cam for G code then bang I had an iron butterfly I posted it somewhere else in here (you can generate a DFX file with ink scape but for me it’s faster in my cad

Tom

Tom, i have started a new thread. Just wanted to let you know just incase you have any more input for me. I am going with inkscape and sheetcam look like. Thanks for all your previous help!

Soooo not sure how much you make a year threw you bussness a year brother but Fusion 360 is free if you dont make over like 100 Gs a year threw the company your using it for outside of that It deos have a few limitations not many but it is avalibel to startup companies an hobbyist. I personally down loaded it at the wrong time kind of preemptively and it expired and neesless to say I was a little frustrated cause I though I lost my free trial. But a friend told me to just go back in redo my info an it let me right back in. Its a great program there is a bit of a learning curve but well worth it should give it a shot.

I make less than 100k but revenue is more than that. When i downloaded it, i did it as a hobbyist. I got a call from then and they said i only qualified for 30 days without any of my information. I asked him about the 1 yr sub for free and he (Alex) said there would be nothing in the program and i would have to purchase it if i wanted to use it for my cnc. I told the guy if i would be able to get the 1yr sub i would be determined to learn the program and would not need any reason to search or learn for another one so after my year would be up i would automatically want to renew it for the same reason of not wanting to search or learn a another program. Then all he did was try and sale me on it which frustrated me a little, so i just deleted the program and let him know i was not going to purchase. I could def see myself doing more with that program, wish i would have known i could have still got the year for free and would have gone that route but there no turning back now. Thanks for your reply

Not anymore. They changed the licensing model several times over the past year. Now effectively if you make money selling stuff you’ll need an annual subscription. The free model is also reduced functionality to the parts they have decided a hobbyist will need which does not necessarily match what you really will want.

If you’re doing simple 2D designs, Inkscape is probably fine. If you want full 3D then Freecad is a good option.

Freecad SheetMetal workbench is pretty good for folded 2D designs.

Thanks for the input guys, im glad i wasnt lied to James haha but for now inkscape is fine. I just want to start cutting! I would like to think 6+ months down the road i will have these programs down pretty good and may start looking into other programs. As always TomWS, you have been so helpful and i appriciate it! ![]() I did start a new thread and your input is always welcome, my set up is inkscape, sheetcam and fire control. Feel free to chime in! .

I did start a new thread and your input is always welcome, my set up is inkscape, sheetcam and fire control. Feel free to chime in! .

For a long time that was why I was using Fusion. Their sheetmetal tool is hugely helpful and why I moved to Freecad vs other free or inexpensive 3D CAD applications. Freecad’s sheetmetal tooling is just about as good as Fusion’s.

Where can I find the plans for that tubing bender?

What are your settings for cutting 3/8"?

Nice work!