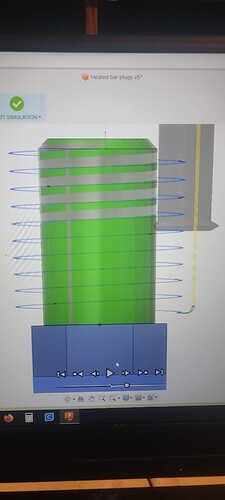

First go of it, got guidance from the NYC CNC page for internal threads and came out great first try. Can’t seem to figure out external threads though. F360 wants to plunge the tool at almost full depth on the first pass and i can’t figure out why. I’ve tried changing the major diameter of the model, verified the tool is setup correctly, played with PDO, passes, and I still can’t seem to come up with a different result. Its just aluminum so I’m sure its fine but its also a small part that i dont want to rip out of the vise and risk damaging the only thread mill I have. Any pointers?

Set it to conventional cut instead of climb and see what happens?

Same result just starts at the bottom

When you selected multiple passes in F360 di you also change the stepover? When cutting 1/4-20 threads I use a .004 stepover with 6 stepovers (passes).

Yes I’ve messed with that also, and it only seems to change every pass after the first. This is a 5/8-11 thread