I have had my crossfire pro for nearly a year now and I initially set it up and was using it with a hand torch and a Miller spectrum 375 x-treme and it was working good and getting good results but I wanted a dedicated plasma cutter with machine torch so when I finally got a better plasma cutter I decided to redo my entire setup and I have been so busy I am finally getting everything back together. I now have a Thermal Dynamics Cutmaster a120 with the SL-100sv machine torch on the table now. That torch has the solenoid valve in the torch so it is pretty long and with it being so long the play in the z axis becomes much more apparent. Basically the torch creates leverage on the z axis and when the gantry moves the weight of the torch cable hanging overhead makes the torch move around while cutting. The vast majority of the play is coming from the roller wheels on the z axis. Is there any way to adjust that play out of the z axis, there is a picture below.

Yes there are adjustments, this is an excerpt from the assembly instructions. You can go look at that if you need additional info. CrossFire PRO Assembly Guide | Langmuir Systems

I have a long torch as well and I sometimes have a little issue with the weight throwing things off.

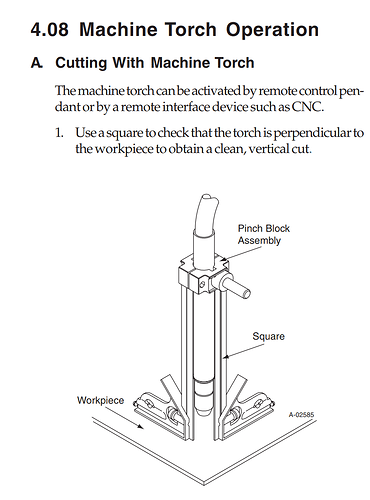

What I’d like to do to ultimately fix the problem is build some stanchion risers so I can have the mass of the torch mostly mounted below the clamp instead of above it.

You’ll see in many other CNC table designs that this is the case.

In the manual for your machine torch and also in the manual for the hypertherm it doesn’t say it but it you normally always shows the torch clamped with the majority of the body below the clamping point.

Next time I do a major overhaul of my table I’ll be adding some very tall stanchion risers so I can mount the vast majority of the mass below the z-axis.

And for sure check your z-axis bearings for play. They can be a bit of a trick.

Too tight and they’ll chatter and bind.

To lose and they’ll shake and wobble.

The spot it matters the most to be tight is at the pierce height and cut height level.

If there’s a little bit of slop above this point it’s not as critical.

I am going to adjust the rollers when I get back to my shop from lunch. Raising the gantry with extended stanchion plates is actually the next thing I am going to do and I have wanted to do so since I got the table. When I searched the forum for raising the gantry I was actually surprised how many people have done it. I know the table was originally designed for use with a hand torch and that is why the gantry is so low. I wish Langmuir would offer a kit to raise the gantry, I was planning on extending the stanchion plates 6". I was thinking about welding the stanchion plates together with a piece of tubing between them or just 2 pieces of flat steel to help eliminate any movement at that height. Raising the gantry will definitely help with keeping the gantry cleaner and it will give me the ability to cut openings in larger square and rectangular tubing.

My biggest issue is a lack of time to work on the table since I have customer vehicles to work on. I was almost better off when I was actually using it when I had a hand torch and the miller 375 x-treme hooked up to the table. I have a weird issue where I won’t use something if it is incomplete or not the way I want it so I end up hand cutting which takes up even more of my time. I was originally planning to wait to assemble my table until I got a dedicated plasma cutter for the table but I was too impatient and set it up.

The one downside I see with using a machine torch is the ability to break the torch if it is crashed, with the hand torch it is clamped at the end so there is nothing to really break. A replacement head for my torch is $350 which is half the cost of a new torch. I also hope they release the limit switch kit soon as that is one more thing I want to complete the table.