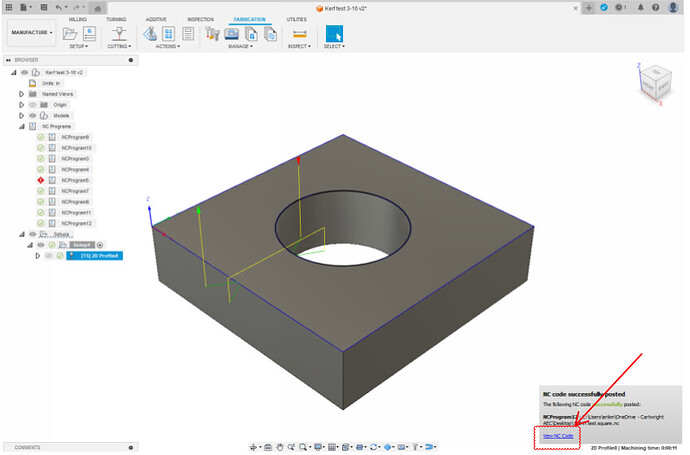

After you post your Gcode a popup will appear in the bottom right corner. click “VIEW NC CODE” it will create a text file that you can copy and paste here.

F3D is you fuision file. here is how to post it to the forum.

Export f3d File and Post to Forum - Software / Fusion 360 - CAD - Langmuir Systems Forum