I’ve searched and can’t find a cut chart for the everlast 62i. Does anyone have one they made?

You can use the Primeweld cut 60 chart as a starting point.

I have just started as well , I have the Everlast 62i and would like to know what you have learned so far. I have only cut .125" so far but it seems to do well at 45amps and 65ipm

I have a 62i…

keep air pressure always the same…60psi on flow check

11g I run at 43amp at 90 ipm

14g I run at 33 amps at 90 ipm…

it all dpends on your air quality and HR or CR metal…I only run HR…can’t afford CR

Thanks @toolboy

I will add to my list

I just cut some .250" Stainless steel at 60 amps and 40 ipm with good results

I got to cut some 3/16" today I used 50 amps and 45 IPM . It did great almost dross at all

Do you have pictures of cuts at these speeds?

Seems really slow for 45 amps.

the first is the 3/16 at 50 amps@45ipm the second is the back side

the third is the back side of the 1/8" cut 45amps @ 65ipm

Please don’t take any of my post as creditable. I have just started this hobby and I am experimenting as i go. If you have suggestions to try PLEASE share.

They look good!

I cut 1/8" at 155 ipm at 45 amps .058 cut height 70 psi air pressure at machine torch. Titanium 45 plasma cutter.

3/16" 75 ipm 45 amps.

Cool

Sounds like I should speed things up a bit Thanks for the input !

Update ! I just cut some .375 at 60 amps and 40 IPM that did pretty good. The upright piece has the slag knocked off with a chipping hammer the rest is as it was cut slag side up

Wow the quake symbol sure brings back memories.

I have the 62i, I have used it a little, cut some 16 GA mainly, last night I try cutting 1/4”, the first piece, cur lost of it, except the top part, the second piece which is the picture, only cut a few inches. Setting are per the chart mentioned here, 45 amps, 60 psi. At times the torch was spitting air, any ideas what this could be ? The speed was 45 ipm.

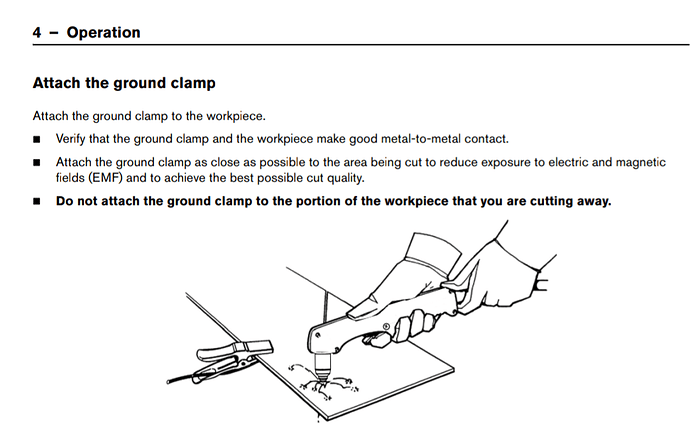

it was clamp to the actual steel plate, not the table

I would check the conditions of your consumables.

Are you running smart voltage or nominal voltage?

What color is the electric arc? Green? Is your electrode hooped?

I did not took a picture of the consumables, but they appear to be fine, but will do later and post it. I am running raw voltage, I follow the recommendations that are on this site

As far as the color, did not pay attention to it.

What do you mean by the electrode hooped?

Does the level of the water can cause any problems like these? I believe the water was about 1 inch below the bottom of the plate.

Also, when I cut the first plate, it started fine, but when it got to the first horizontal cut (which is the top of the picture) that is where it started malfunction, then as it started going south, it cut fine again, I had to use a grinder to cut the top part.

I would scrutinize the quality of your consumables.

Take a good picture and post them if in doubt.

The electrode is where the arc comes from in your consumable pack. The nozzle focuses that arc into a proper stream.

If it’s burning green it means that it’s actually burning the copper because the hafinum emitter (which is a element that can withstand very high temperature embedded in the electrode where the arc begins) is gone.

When I asked the question whether it’s smart voltage or nominal voltage you’re using those are your options in fire control under the THC.

Raw or divided voltage is how it’s measured.

Smart or nominal voltage is how it’s implemented.