Hello George,

Thank you for the great information.

Can you tell us where this chart is located. Is there some kind of general plasma cutting manual it is in that we might access for better copies?

Respectfully,

notmeofficer

Welcome,

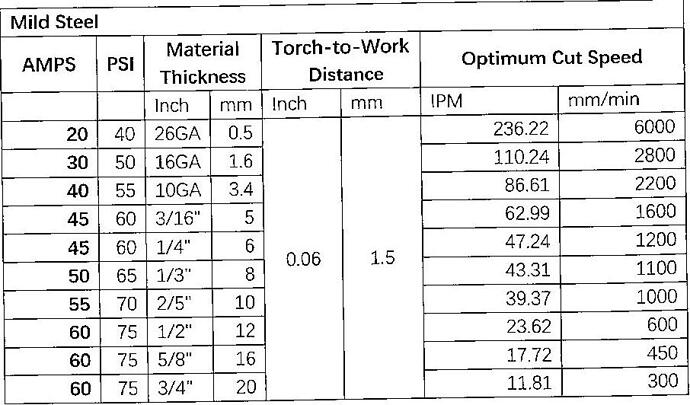

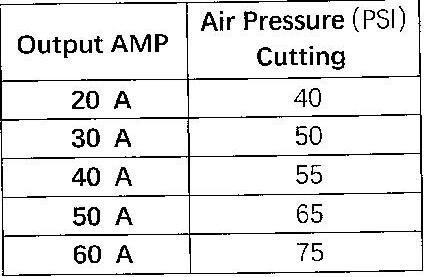

Lets try this and see if its better. Keep in mind these are only start settings. Also some plasma cutter will not pilot arc/work at air pressures below 50 psi.

Thank you Very Much Sir.

there is some great information in this thread for Everlast users…I would like to bump it up so we can share motre information on our own cutting settings that we have found work best with Everlast and the Crossfire and crossfire pro…

Just reading through some posts today and came across this one… I will start by saying I’ve got the Everlast 50s here in the garage and honestly, I’ve only fed the torch one PSI since the very beginning… 75 to be exact… This has worked for me in cutting anything between 16ga and 5/16" material…

For sake of discussion, I see where the tables above call for 50PSI as a starting point for 16ga mild steel… I currently cut this at about 32A and believe it or not, at approx 165IPM… .8mm tip and 75PSI… (I realize these in the table are only starting points and you should fine tune them from there.

Aaaand there are going to be those that say “Hey man, if it works for you…” Yup I agree…

I think I will give a little time to playing with pressures to see what happens… I can certainly see where having the pressure too low will be a problem… But, is there a point where it can be too much?? And what effect does/would it have… Just curious about this today…What do y’all think?? I’ve never toyed with this part of the equation…

Opinions welcome!!

Yeah. It can blow out the arc or spatter the molten metal before the arc can eat it. You can see the first when cutting really thin stuff (like 22ga or thinner). The latter sometimes will show up on aluminum.

I tend to play with speed more than any other factor. Then power. PSI is the last thing I mess with.

Thanks @jamesdhatch for the response… I guess at the very least I’d find out if by turning down the PSI perhaps my compressor wouldn’t cycle as often which is not an entirely bad thing… I’ve got some drops here I’ll mess around with next chance I get… Time will tell…

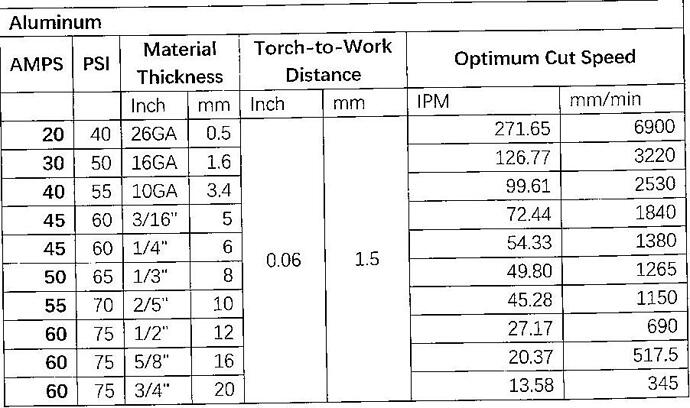

Good morning ! I would like to buy good quality tips and electrode for PTM-80 machine torch 1.3 mm and later 1.2 mm . I check your online store but was not sure what is the best for my use ,shield unshield , cap ect… to have a good setup .I have a Everlast 82i plasma cutter ,torch machine PTM 80 . I need to cut steel up to 5/8 inch ,stainless steel up 5/8 inch ,aluminium up 1/2 inch .I am biginners ,and I try to find maximum information who can help me ,chart cut ,all good advise , to be on the right track . this forum bring lots of good informations and all user are Longmire team are super If you would send me information by e-mail at : atelier.gillesvigneau@gmail.com