The Everlast 50S, 60S and 80S are good plasma cutters. But you may want to check out the Primeweld Cut 60 its CNC ready and on sale.

Well, The 60s I ordered came in today. It seems well made, the clear cover for the control panel is a little flimsy and not well designed but the rest seems ok, I was glad to see the CSA approval but i’ll double check the bonding anyway. it uses a breaker (supplemental protector) as an on of switch (wouldn’t be my choice). They sent me a “starter kit” and the consumable package I ordered but all the nozzles are the same size and I think they are wrong. They are all 1.2, the one in the torch is a 1.1 and I think the biggest they list for the 60amp is 1.1. All the nozzles seem to be for the 80s

Those are what they call flat tips. 1.1 is the 60 amp tips. 1.2 are 70 amp tips they will still work at 60 but not as well as the 1.1’s will.

The tips will not fit the 80S they are different.

I emailed them, hopefully they will change them out for me. they have no charts for this machine so I was hoping to make my own but now I don’t have a variety of nozzles to do it.

0.65mm - 20 amps

0.8mm - 30 amps

0.9mm - 40 amps

1.0mm - 50 amps

1.1mm - 60 amps

1.2mm - 70 amps

1.3mm - 80 amps

After this it all depends on the torch or plasma cutter on the size.

well that was less than encouraging. They only carry the 1.2 tips and basically told be to go somewhere else for anything else and to use Trafimet part numbers to get the right fit. but I wonder if all the electrodes work with all the tips?

thanks for this I will have this list in front of me when I call praxair

If you need consumables for your plasma cutter I carry them all, call me.

Trafimet consumables do not fit your torch.

Lol… well… Why would they give me such bad information ?I think one of the girls there tried to tell me about not mixing consumables because they don’t work well but a flat out doesn’t fit is a bit of a surprise. Do you export to Canada ? because I will need consumables for sure.

Yes I can ship them to Canada

You have a IPT60 torch made by Tecmo

Ok maybe you could send a price list ?

send me an email so I can find out what you may need as there are a lot of consumables for that plasma cutter.

Do you have a chart or some info on how thick you should be cutting with each of those tip sizes? I ask because I was cutting 14g with the 1.1 at 25 a fine at 100 ipm but when I switched to a 1.0 size it wouldn’t cut through it at 90% speed.

I haven’t gotten my table yet but i’ll start making one once its here and running. Also everlast is not supplying all the diferent nozzles so I only have 1.1 and 1.2 on hand so i’ll get the other sizes on order and build a chart as I go. I haven’t found anyone thats made a chart for Everlast.

A 1.0mm/50amp shouldn’t have made any differences over the 1.1mm/60amp tip running it at 25 amps.

1.0 and 1.1 tips at 75psi flow should be for cutting 1/2" +

0.8mm/30amp tip at 60psi for 14 gauge should be more then needed.

This is very important always make sure your work clamp is connected to the metal being cut. If you hook it to the table then use a jumper from the table to the metal

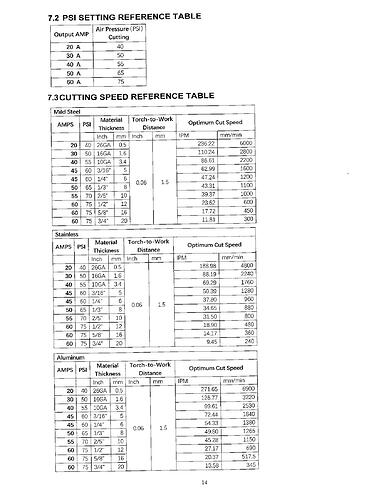

This cut chart should be close.

what happens if you run 75psi on 20a cuts ? does it blow the arc out causing restarts ?

Basically yes, the amperage can’t sustain that much air pressure.

Will this chart work with the 50 amp machine?

Yes the chart will work with most plasma cutters. The chart is just guide lines. You may need to change the settings a little to get the best results.

Thank you George!..