hello i bought a brand new 82i and a used crossfire pro. the plasma is cnc ready which is the best way to hook up the system. any pointers are appreciated thanks Jon

You will need to look up the instructions off of the Langmuir main website.

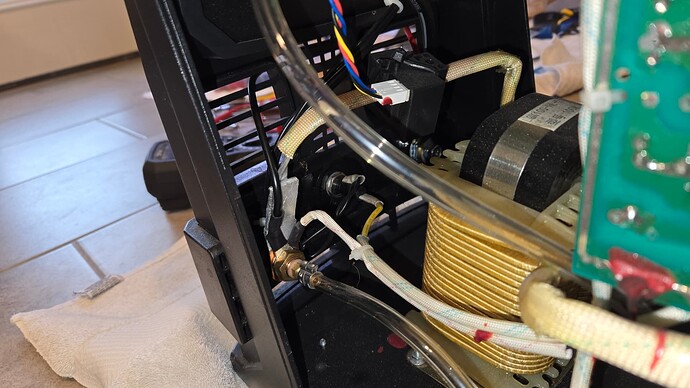

You want to hook up raw voltage off the plasma cutter to the Vim box on the plasma table.

Then use the CNC Port connected to the control box to fire the torch on and off.

This. Only use the CNC port for the on/off signal.

DO NOT use the CNC port’s reference voltage for the THC system. Go straight off of the main outputs

The 82i has a 50:1 voltage divider, stock. Why wouldn’t you use the CNC port? I’m about to start wiring for my 82i, so this is of keen interest to me.

Just wire it for RAW voltage from the terminals for a lot less trouble. CNC port for the trigger wires is OK.

Thanks, @mechanic416 This is my first CNC plasma and I’m trying to do things right the first time. I have read a few posts about inconsistent performance when using the Everlast CNC port voltage signals, but nothing real definitive. A lot of variables there. Bad solder connection, wires picking up other EMI, etc.

Hate to open up a brand new machine and likely void the warranty, but the direct wiring seems very simple. Besides, I’m not thrilled about having to solder onto those microscopic pins on the CNC connector. So, the less pins I must solder, the better. I have one of those lighted magnifying glass things on an arm, but it’s difficult looking through that and using tools. Might be easy if you do that everyday but I sure don’t.

Your not going to void the warranty. Just run the wires through the air vent holes.

Thank you. I’m in the process of doing that now, in fact. Trying to figure out some strain relief for the wires beyond zip-tying them to the air vent slats. I’m toying with the idea of drilling a hole for a gland/strain relief. But drilling a hole in the front fascia will 99.99% void my warranty. It will likely be zip ties for the win. Zip ties and duct tape have held my life together for years now.

And done. THC is hooked up to the 82i via raw voltage. I chickened out on my idea to run a gland through the front panel. I’m just not going to drill a hole in my brand new plasma cutter and void my warranty before I’ve even used the thing. Maybe later though as the wires running through the front grill triggers my “that don’t look right” anxiety.

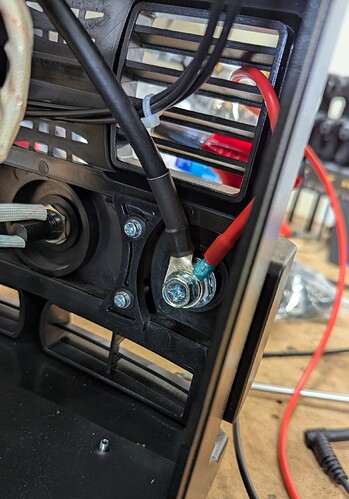

The black/positive lead is more secure than it looks. That is a large ring terminal with just the top of the loop cut off so it fits around the bolt.

The silver nut on back of the positive/clamp bolt is 13mm and it’s stupid easy to get at with a socket and short extension.

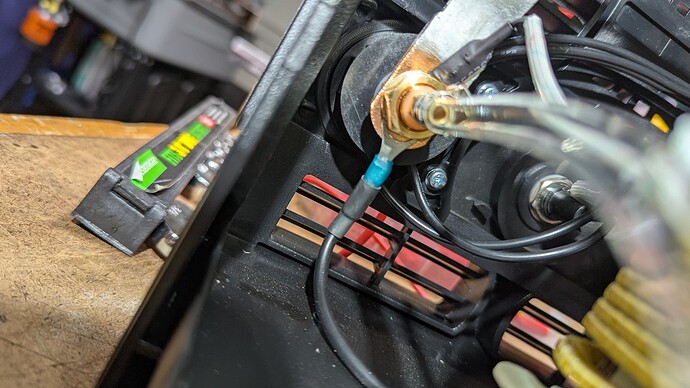

The negative/torch lead bolt is a different story. It is 11/16" (or that is the wrench size I could fit on it) and unless you want to risk breaking stuff by using a pair of Channel Lock pliers to get it off, you will need a crow’s foot wrench. That connection is easily visible but not so easy to get your fingers in there to turn the nut.

I can count on one hand the number of times I’ve used my crow’s foot wrench set in the past 5 years. Today was one of them.

I thought about trimming the THC leads to length for neatness, but I decided to keep them long in case I ever need to disconnect and re-run them for any reason.

Oh, because someone will ask: The blue painters tape over the lead connections is to keep dust out while the leads are disconnected. Yes, I do in fact OCD a whole lot. ![]()

Good Job Mike. I have the 62i and can tell you that you can’t be shy about working on these machines. I’ve already had to replace the solenoid once and have taken it off and cleaned it a couple of times. I think I’ve taken the cover off of my plasma 6-10 times already.

I don’t know what your air drying/cleaning system looks like, but do not underestimate the need for dry clean air. Unless you are in west Texas, you are going to have the same humidity issues that I have in Baton Rouge. Get the air as dry as you can afford to.

Have fun, welcome to the forum/community,

Adam

Thanks, Adam! One of the reasons I went with Langmuir was this forum. It was really impressive to see the level of community and manufacturer support. Made the decision easy for me.

Funny you should mention the air system. I’m in the San Antonio area so the humidity here is lousy, just like where you are. From roughly this time of the year through November, the temp in the garage never drops below the low 80’s with anywhere from about 35-50% humidity. You just die out there in Jul/Aug/Sep.

I didn’t buy the Crossfire Pro or the 82i until I finished my new air system. I just spent the last 2 months redoing the air system in the garage shop and I think it’s finally done. I don’t have a bunch of drops all over the place, but I do have a system plumbed to a manifold that feeds a hose reel, a laser engraver and drops for the plasma cutter and water table drain/fill system. Well, as soon as I build the Crossfire and the drain/fill system, anyway. Working on it.

I bought a new 80-gallon/5HP compressor, a good filter/regulator setup and a proper compressed air dryer. A huge investment for me, but good tools are not cheap. I use a lot of compressed air and water has ruined many tools and rusted out air lines over the years. I ripped it all out and started over from a clean sheet.

Over the years I’ve had everything from the 3-gallon pancake compressors to a home-built 80-gallon compressor that ended poorly. Also had the home-built air dryer from 50 feet of copper pipe, the aftercooler made from a transmission fluid cooler and everything in between. Nothing really kept all the water out of the air. Best I ever got was probably a 50% reduction in moisture. Not good enough for plasma cutting and not good enough to keep from ruining a compressor pump, a bunch of tools, rusting out air fittings etc.

I’ve wanted a plasma table for a long time and know the crucial role that clean, dry air plays. I know next to nothing about automated plasma cutting, but you have to start somewhere and I want to learn.

Dang, that all looks familiar… ![]()

![]()

At least you’re not in Little Louisiana like me… ugh, Houston.

Yup. ![]() I looked at your pictures and was surprised at how easy it was to connect directly to the torch/ground terminals. I’ve never opened up a plasma cutter before so really didn’t know what to expect. On a scale of 1 to 10, this was squarely a 1.

I looked at your pictures and was surprised at how easy it was to connect directly to the torch/ground terminals. I’ve never opened up a plasma cutter before so really didn’t know what to expect. On a scale of 1 to 10, this was squarely a 1.

Most people using a plasma cutter have some technical skills or background, so taking off a bunch of screws and putting in a couple of wires is easy stuff.

Thanks for sharing your pics, BTW.

I’ve been to New Orleans a few times as well as Shreveport and those places are the humidity capital of the USA. San Antonio is not exacly “dry” but it’s definitely not southern LA.

I lived in Shreveport for about 6 months when I was in my early 20’s Unfortunately for me it was from May to October. ![]()

![]()

![]() Somewhere I have a picture of myself sitting on my bike in front of the bank sign. If i remember right it was over 100 degrees and over 90% humidity… Those bank signs always exaggerate… but it made for a good picture!

Somewhere I have a picture of myself sitting on my bike in front of the bank sign. If i remember right it was over 100 degrees and over 90% humidity… Those bank signs always exaggerate… but it made for a good picture!

Lifelong resident of Southern Louisiana here. Every year around the first week of August, the world is literally dying around us. Two summers ago, we had a high-pressure system that stayed over Louisiana for about 2 months. We had 20+ days in a row where the highs were over 103f, with very oppressive humidity. It never rained either, severe drought with 80%+ humidity is weird man.

Too hot to allow it to fall out of suspension in the air, and stays hot because of all the extra mass from the moisture. People think that CO2 is a bad “greenhouse gas” really don’t understand water.