Has any one every had this happen? I was running a cut when the torch kinda started gouging for a section then went back to cutting. So I thought the electrode might be worn, so I replaced the consumables and started to cut. Machine went about 6 inches spewing out sparks before I could stop it. When I did the checked the torch head and the electrode was welded into the the torch head. Tried to take it out but broke off. Fortunately my machine is under warranty and they are sending me a new head. My question is what would cause this, and how to prevent it happening again. Cutting 16 gauge a 40 amps 110 ipm 60 psi.

Probably not the answer you’re looking for as I only have experience with the screw in electrodes from Lincoln plasma cutters (Tomahawk) and PrimeWeld (CUT60).

Haven’t experienced that issue happen to me, but it did happen to a friend on his Tomahawk. Happened likely due to a loose electrode. I always check my electrode before cutting, as sometimes they can work themselves loose. I was with him when it happened and I remember asking if he checked the electrode before cutting a bunch of stuff; he admitted he didn’t.

My friend experienced the exact same on his CUT60 some 2 weeks back, but he blames having run the electrode on too long. Although when I asked him about the electrode being torqued down, he admitted to only going hand tight and never checking it between long intervals. I’m almost betting that was what happened with him.

I’m sure someone with more experience will chime in though.

Thanks for the response. Mine is also a thread in type. I use the wrench that came with the machine to snug it up. So loose is not on the list.

You can not repair it, many, many, many people have tried and failed… You will need to replace the torch head.

I recommend getting a 5mmx0.8 thread plug tap and die to keep the threads clean and the die to clean the threads on the electrode.

I have had that happen to me but not to that degree. I believe that it is blow back when the torch does not pierce 100% of the metal. Now I know I will get some more hate mail for this… If I’m going to cut a $250 piece of steel or stainless, I put in a new tip and electrode. Cheap insurance policy. Just my two cents. Now if you are cutting out small widgits than fine keep rolling.

I agree 100% with that ![]() for $10 or so for a tip and electrode its not worth messing up a nice sign or big cut out.

for $10 or so for a tip and electrode its not worth messing up a nice sign or big cut out.

@bigjeff you are lucky as in most cases torch’s are not under warranty.

It was a new tip only cut for 6 inches. Now have to get a new torch head. The one I have is bran new. Was hoping for a solution to prevent it happening again. I guess there are none.

Yes there is as I posted about the tap and die. Also if the electrode does not screw in by hand and screw out by hand you need to clean the threads electrodes only need to be snug no more then that and never leave them loose as it will arc between the electrode and plunger and you will never get it out.

There are people on here as well as others that have had their torch’s for years and never broke off an electrode.

I run a 62i…and have for almost 3 years on my table…

I have run into all kinds of issues…from water infiltration to torch head…warped torch head…

most of these problems are often lack of post flow air in my experiance…Everlasts like a good 30 seconds of post flow…

BUT…

looking at the photo in blown up mode…that is one dirty head…the threads are covered in dirt

I see you had opened the torch…what does the rest look like?

what does the tip look like…?

I am thinking there was water or somethimng in the air line that shorted out the electrode…be is splashback…something in the air…

could you post more pictures?

It was dirty because I was rolling it around trying to get the electrode out. Which is welded in and broke off. Every thing inside is good as if that matters at this point because the whole torch head has to be replaced. Even though it only a couple of weeks old.

You can buy just the end Jeff. It won’t be that bad. Just contact mechanic416. He will get you going real fast.

It does matter in trying to help solve your issue.

do not take what I am asking as hunting for witches…all I want to do is help you from having this happen again…I know how frustarting this is…

I know what you are going through…I have killed 2 heads over the last 3 years…

1 was from water splash back…and 1 was from lack of post flow cooling.

how much cutting had you done before this happened?

I have learned to check the electrode for being snug at the start of each day…and after putting in new ones I will check it after a few cuts.

and when I feel even a little resistance from threading in the electrode I grab my tap and give the threads a little cleaning…

this has helped me stay burnout free for almost 2 years…

lastly…using good quality electrodes…not the ones you buy off Amazon…get ones from the dealer of from someone like @mechanic416 …George sells quality stuff.

Thanks for your input. I seems no one really reads what I post. What I was referring too when I said it doesn’t matter is the torch is toast and a new one is on the way. Plus it was a brand new electrode and tip when this happened. What everyone is saying you have to replace the consumables every cut and re-thread as well. I can see having to do that every so often. My machine is several weeks old. I will take the water splash back into consideration. Like I said in my posts only made about a 6 inch cut when this happened. It’s starting to appear that I should not use the crossfire table or plasma cutter because it’s so delicate and should be put in the corner for display.

Thanks again for everyone’s input, this is now closed

wow…you are reading this all wrong…

I am sorry you feel this way …

I am wondering if your issues with the broken z axis wire/ Firecontrol freezing issues, may have contributed to the problem? Did you change your consumables after you resolved the problems you were having with the THC? When the arc freezes on with nothing to cut it can fry the electrode pretty fast. I can’t say it’s the same as what you described above but I have had an electrode burn through the hafnium on a cut and it gets a little exciting somewhat similar to what you described. Did it start burning green before the sparks started to fly?

It happed to me at the end of a fairly large cut file. I was able to salvage the piece using the run from line feature, but after that happened, I make sure to check my electrode before every session as others have stated. And I probably change them out before I really need to, to avoid the excitement.

I know you marked this solved but reading through it, I remembered your other issues earlier on and thought this might be helpful.

Good luck going forward. I am sorry you have been having so much trouble. Hopefully once you get the new torch you can get to cutting and not have further issues.

I learn something new every day with this hobby. Still working on improving my air quality nearly 2 years in.

Erik

I have never had to run a tap in my threads.

There has got to be a joke in that declaration! But I won’t make it. ![]()

Got new torch and consumables from mechanic 416. Tried to cut a project everything went well till the last cut. Go about 3/4 of the way around then pulled up and gouged the metal. At least this time it was a straight cut and I was able to cut off with shears, so didn’t ruin the piece. Now I am being told it’s moister even though I have 2 dryers on the system and keep my tank drained all the time. My drift it has something to do with THC. Have contacted langmuir support and will see what they say. I have read a lot of posts about the THC doing that so we’ll see what they say.

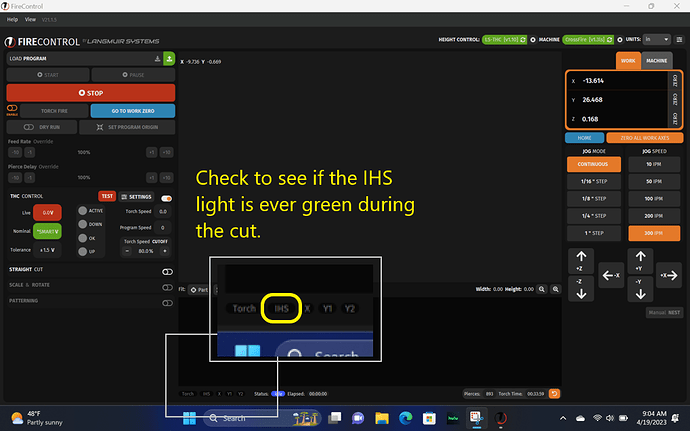

So sorry that happened. You did not happen to see if the IHS light turned green during this moment when the torch was rising?:

Learned this from @ds690. If the light turns green it is because the contact in the z-axis thinks the torch hit the metal. This can be from a loose wire, connection, break in a wire, or dirty contacts of the IHS switch in the z-axis. This will send a signal to raise the torch 0.06 inches and keep repeating that command until the light turns off.

The light, in question, will be green around this “IHS” symbol.