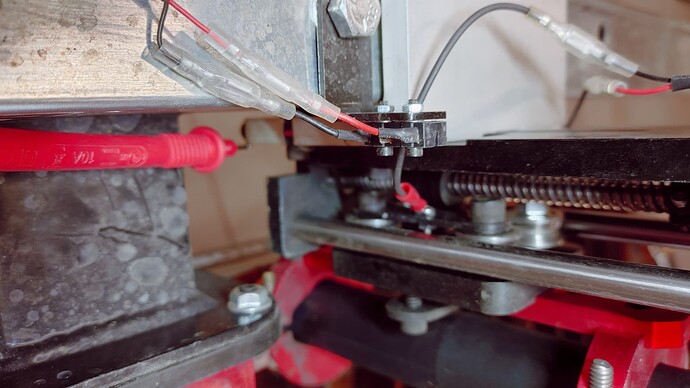

It happens so fast it’s hard to catch. I have been checking things and have a curious thing. On my Z axis the black wire (see pic) connects to a plate between the 2 bolts. I am assuming it’s a ground. The curious thing it appears that the plate is plastic and there is no continuity between the screw and the plate. I have looked on the forums and found a few pictures that show a brass like plate. Why would it be plastic and non conductive? Also when I test the screw back to the plug on the other end ( plug at controller box ) 2 of the pins have have continuity. Not sure if that’s right or not. Have sent this to support to see what they think.

That IHS circuit is a simple open or closed loop. It is normally open until the torch is lifted and closes the contacts to complete the circuit.

If it is working correctly, you can watch the IHS light turn green when you lift up on the torch and then turn off when you let the torch drop.

Your right about it being a simple open and closed circuit. The problem is it does not work most of the time. I have found wire problems from the factory. It has ruined a few hundred dollars worth of materials. Every other project I try to cut it will burn up the tips. It will cut fine then rise up about 2" and score the metal and warp it. then go back to cutting and when it gets to the warped part it drags the metal in the direction its going. Last project it went halfway through then plunged the tip to the steel stopped and the new electrode was melted and tip plugged. All the lights showed a okay till it melted down. Put and new tip in new consumables started to run a new project, went along for a while then did the same thing.

I know I will get a bunch of crap that its my fault or ground loop or 5 gallons of water in the air line. May also be Trumps fault. My solutions is to scrap the crossfire and find a better unit. I have had a plasma cutter for years and have never had tip problems like this. Have run straight tests like everyone suggested goes fine till I try to cut a project. Just a bad machine OH wait I’m to stupid to run it.

Sorry you have had so much trouble. Good news is you won’t have to scrap it. The used market on these is pretty strong. Put it on KSL and you will prob get close to what you paid for it.

You aren’t the only one to have problems. Interestingly it always seems to be the smartest most experienced people who have the most issues. I had 0 CNC experience, can barely run a multi meter and had very little plasma experience beore buying the Crossfire Pro. There was a steep learning curve in the beginning. Probably dumb luck but somehow I have had good results with my table. In fact, I really like my cheap bad machine. There are certainly better burn tables out there… just not in my budget so I feel pretty fortunate that my bad machine has worked so well. Really it has very little to do with me tho. The only thing I had going for me, I suppose, was I didn’t know any better so I sought out and listened to the bad advice I was given here on the forum. If I had 40 years of experience to lean on perhaps I would have seen from the beginning all the problems with my budget burn table and I would have scrapped it long ago for a better more expensive model.

Wow that’s a expensive solution, you don’t want to try and figure it out?

The reason you might get a bunch of crap about that stuff is, time after time its the same story on here.

This stuff gets overlooked, Then at the end it turns out it was one of those things that was causing the problem. Its pretty hard to trouble shoot things with out being there to see what’s going on.

Another problem that happens on these long post’s is you get a lot of information from people.

Sometimes they are in a hurry and don’t read what you posted and miss things. So sometimes there advice is not correct.

If I were you and you still want to find a fix, start a new post. You now have a better idea of what info people need, and you understand what might be going on better.

I will share somethings that will help you, you can take them or leave them.

1 - Quit cutting projects until you get it fixed.

2 - Quit venting on the forums (I like my table and it kind of pisses me off when someone says its a piece of junk) We know your not happy, lets just get it working!

3 - Think about the information you get from here, there are some very very sharp guys in here (not me) and then some guys who are just so-so (me) Figure out who the smart guys are and listen to them.

4 - Remember everyone here is just trying to help, if it was not for these people in all the forums online think of where we would be today!

I Go online everyday and get info, ideas, help you name it and 99% of it is for free

Now are you going to fix this or sell it?

Look for local high school to give it away. I’m sure they’ll be happy to receive it. Hopefully you have better luck with different unit.

It seems like everyone on here is way smarter than me. Maybe someone can explain why this keeps happening. halfway through this cut the torch goes down and melts the electrode and tip to the metal. This was new tempco consumables at start. I have spent a lot of money because it takes 2 of these most every cut. I have been told that you have to replace them every cut. Seems crazy as my other hand plasma cutting the tips last a long time. This keeps happening over and over. Not every time but most of the time. I have run this by support a couple of times and they just give me some excuse that does not really work. So if one of you has a solution that works I would be glad to hear it. I have been trough all the trouble shooting checked every thing that can be checked. No one seems to want to say that there is something wrong with the machine.

First question. Have you tried to cut without the THC on? If so how did it act?

Seems to be a THC issue. How have you pulled voltage from the plasma?

It seems to cut fine with THC off. I have raw voltage. I keep saying its a THC issue.

Thanks for you feed back.

you may want to dig into the pinned thread in the thc section it is a trouble shooting guide for the thc.

Some good information on THC here…

https://www.hypertherm.com/en-US/resources/articles/torch-height-control-for-plasma-cutting/

That thread posted by Donp is explaining how THC works, so it does apply to you …No matter what plasma cutter you have, The THC is dependent on what the manufacture is using on their table not what plasma cutter.

What cut and pierce height are you running ? too high = too hot

What are you doing to separate the water from the compressed air?

Re-mount your torch so you are not clamping on the lower plastic. (most people have to flip the red part of the mount) Maybe the blow back is not opening to a wide enough gap because of the clamp.

During these tests keep your air at 85psi also have a gauge that you can verify the 85 psi at the back of the plasma during cutting.

I did read the hypertherm thing okay I understand that. Okay back to water in air again. I have a separator at the compressor a 3 stage dryer on wall @ hose connection, and the one that came on the back of the Everlast 62i. There is no water in my system. And please don’t explain again about compressed air.

Thanks

pierce height .15 I have a machine torch which is brand new as the THC welded the electrode into the old one. My cutter has a gauge showing pressure. My compressor is 12 CFM and runs at 175 PSI hose is 3/8 ID so I have plenty of air.

So what are the THC settings supposed to be?

looking at your last picture a few possibilities.

what is your cut settings? material amps ipm.

another possibility if the torch holder is holding in the wrong place and or is too tight. it will restrict the blow back feature from working. looks like you are running on pilot arc only.

another option is shot consumables.

Post your .nc file

This how you ask for help? Good luck pal!