so i have been using the razorcut 45, has worked really well so far. i upgraded to an everlast 102i and was wondering if anyone has come across or put together anything for a cut chart. Nearly all the cut charts i have found reference arc voltage instead of amperage. is there a conversion formula for arc voltage to amps? sorry in advance if this isnt in the right place. any help is greatly appreciated. thanks

Welcome to the forum.

So if you went to the 102 that tells me your going to be cutting metal 1/4" and thicker as the smallest cutting tip is 1.0mm/40/50 amp.

Cut charts are only a starting point. The best cut chart is the one you make as your setup will be totally different from anyone else’s.

If you were looking at the Hypertherm cut chart, you have to under stand those charts are made in a lab with a $50k or more setup and Hypertherm plasma cutters have about 20% more wattage power output then all other plasma cutters out there.

You can cut 1/4" mild steel with 40 amps at say 45 ipm, you can also cut 1/2" at 40 amps at say 20 ipm. Now if you want to cut the 1/2" faster you need to up the amps so you go to 80 amps then you can cut it at say 72 ipm.

Voltage readings will also change with torch height/TH. Say you set your TH at .060" and 50 amp, volts may read 128. Then you set it at .085" and it will read 137 volts as the longer the arc the more volts it will put out to close the gap. This also puts a lot more load on the plasma cutter and will pull more electric amps.

Don’t get these voltage readings mixed up with the THC voltage readings. But they can also affect the THC.

TH is also changed with amperage 20 to 30 amps work best at about .045", 40 to 60 amps at .060", 70 to 80 at .07, 90 to 100 at .080".

I would also recommend using CNC shielded consumables on your Everlast 102i on the table.

I hope some of this will help you out. If you want you can contact me and I will be happy to help you out with your questions.

thank you for the response. i am going to run the machine torch. i still have the razorcut 40 for the small stuff. i kind of figured that i would have to sort out a cut chart on my own. but it was worth a shot. i am guessing by cnc shielded consumables you mean a machine torch etc. thanks for the offer to assist me further i will most likely hit you up again as i travel down the rabbit hole.

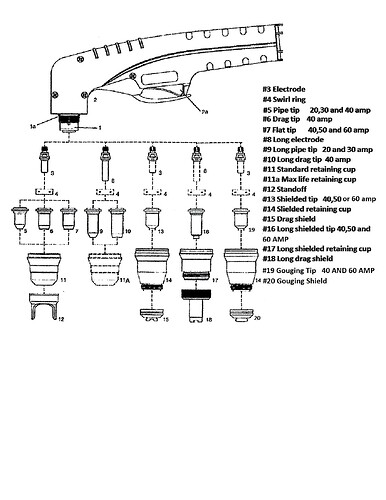

These are all the consumables you would use if you were hand cutting.

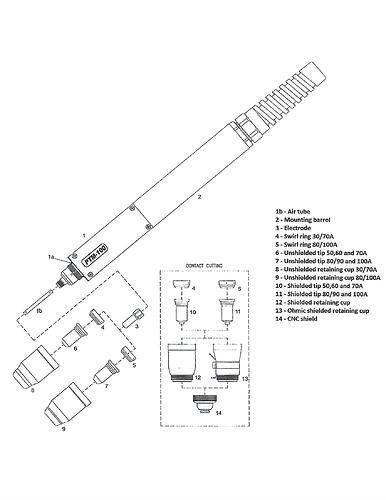

Here are the consumables you would use on a CNC table, using a hand torch or a machine torch.

I carry all the consumables for the PT100 and PTM100 torch’s.

one thing to keep in mind with Everlast plasma…always…always…run your post flow for at least 30 seconds

You need post flow on all plasma cutters and 30 seconds is a good setting.

Note: Plasma cutters over 80 amps like the Everlast 80s,82i and 102i should be set at 45 seconds to cool the consumables and torch after a cut.

also…Everlast recommends that you try to put a pause in cutting after every 3 minute continuous cut…