So after the concrete cured for a week I brushed on the tack-coat and waited 6-hours. Did the flood-coat and it came out awesome. Shut down the shop and called it a day, little did I know it would rain (never rains in AZ) and had a roof leak! Part of the flood coat is hard as a rock, and some was just pooling. I took a puddy knife and rags and scrapped off all the gooey stuff - took a while to get down to reasonably stiff stuff, but it’s been tacky for a week now, tried heat gun and have garage temp set at 80 - no progress. Probably took off 3/32"-1/8" - can I reflood coat and will it cure underneath??

I recommend removing any epoxy that isn’t fully cured. Scuff up what’s left with sandpaper, and then repour. It will turn out fine.

Also make sure you REALLY mix this stuff well. It really needs to be be mixed perfectly otherwise you’ll get areas that aren’t cured properly.

The fact that most of is hard - even in the mixing container - suggests I got toughly mixed. I did try to remove the softest stuff in a small area and got down the concrete. But man i actually so stiff i had to cut it with a multi-tool - only the tact coat was dry, piece i took out was sticky. So, scrap it really well, sand the hard stuff and reflood?

Make sure when you mix your epoxy that you do so for a couple minutes in one container, then transfer to another container to continue mixing.

You’ll find that even in a few days, container #1 will have sticky (not fully mixed) epoxy in it, while the remnants of #2 will be nice and fully cured.

My 2 cents. I wouldn’t recommend using multiple containers. I would mix you parts A and B into one proper mixing container and mix it well occasionally scrapping the sides and bottom of the container to get the stuff that may be stuck there. During my final pour, I may have mixed/stirred for about seven minutes. (Speaking as someone who poured the epoxy and had to completely rip it up… poured again, got a tacky surface had to sand/scuff and pour a third time.) I thank God that ordeal is over and my MR-1 was saved!

Many articles on this topic - most will recommend the 2 container method to avoid the situation you describe. There is no downside to using two containers, only a much higher probably that the mixture will be consistent when poured.

Where in AZ are you?

North/central Phoenix

Part 2 - It’s been 10+ days now, so I dug out the soft-gooey stuff - in one place about 2"X4" down to the top of concrete. Scrapped as much of the tacky surface I could with a scraper hoping it would cure - notta. So yesterday I mixed up about 3oz and filled the hole and did a 2" square patch over some tacky stuff and today, it’s hard, no sticky. I guess I’ll order up another kit and sand/scuff and refloat the base.

amazon has some deals with prime shipping for the same stuff with mixing containers included, gray liquid dye was hard to find tho, but a layer of clear over the top would probably look great if you got 100% coverage.

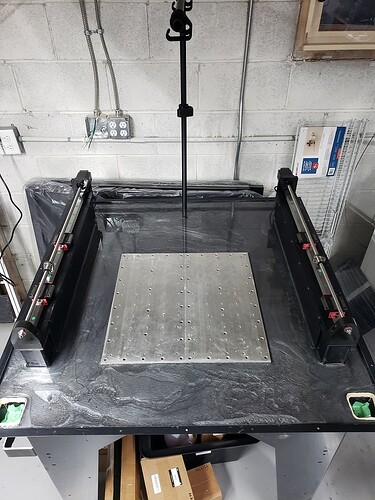

Thanks VGT - I went that route. First I tried scrapping off the sticky surface areas hoping it would cure - no luck. So out came the multi-tool, first with the scraper - not effective - then with a bi-metal blade and got off all the sticky/uncured epoxy. whipped off dust with acetone and sanded slick spots and reflood coated yesterday. Now i have a hard/clean surface and move on the the Y-rails.

In doing the repour I found out what happened. While I’d like to blame it on the roof leak, it looks like my screwup. Doing the repour, I mixed up about 8-oz of 1:1 in a large container. I needed to mix up a little more to fill in a few spots and used a new/smaller mixing container - I almost did it again - I poured the first part up to “1” and then added the hardener to the “1” on the 2:1 line…arrggh, caught it in time, whew. today we’re hard slick and level.

I have the same issue, tacky epoxy in some areas and hardened properly in others. Did you remove only the tacky areas? I was anxious to continue so I have built the machine up to almost the point of starting the cutting

I had the same thing happen with a couple of spots on the surface. I am pretty sure that the epoxy mix was a bit too cold to get a full mix. Winter in Minnesota. I ordered the same epoxy from Amazon and picked a color that would completely cover the grey. I dug out the soft stuff, mixed a new batch, spot filled and then did a pour over the complete surface. I made sure that everything was above 75F and I set the temp in my shop to 80F (can’t wait to see the bill for that). The upside is that the drains are now a bit below the surface so I can squeegee over the top of the drains without hitting the grills. Plumbers putty and a bit of mold release was used to build dams around the drains.

Where you at in Minnesota, I’m in Medford still awaiting mine

Independence, just west of Minneapolis.

Mine should be on a truck to Minnesota this week