I’ve seen people talk about it but haven’t seen anyone do it yet. I have some measurements planned out to move the drains slightly toward the center in order to have a drain path straight through the concrete in order to clear any possible blockages. I have some measurements, just need to model some new brackets. Anyone gone here yet?

Nope was was planning to use some 3/4" pex and drill new holes to go straight down - it also gets the lines out of the center in case you want to do a cabinet etc. I am slow, still working on welding up my base…

I don’t understand why those drains don’t just go straight down in the initial design. A bunch of 90’s with small diameter tubing and fittings enclosed in concrete (not serviceable) seems like an odd/expensive design decision.

The drains wiill have to be moved slightly to drain straight down as “straight down” runs into the sloped edge of the pan

-6 bulkhead fittings and some 3/8 fuel line hose and some 3D printer time would likely do wonders.

I am thinking they put the drains at the corners to keep the cement thickest around the crossbars going to the posts on either side for y-axis rails.

The corners are essentially a non-structual place to put things. The tubes running horizontally to the drains could potentially help reduce tendancy for concrete to crack within that length.

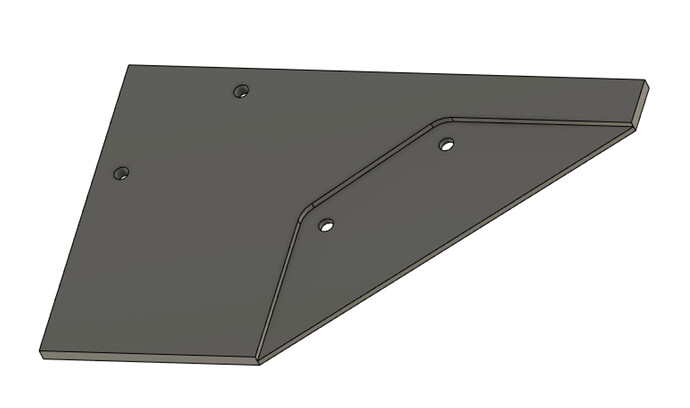

Have a model prototyped, printed a couple skins for hole position tests still have a little tweaking to do. Here’s a photo of what I’ve got. I plan to add some cutouts for print time reduction, would appreciate any further ideas… You are looking at the bottom of the bracket. There’s a .100" relief to put the drain at the original height. Relief dimensions are only estimated right now as I don’t have a caliper with me (out of town). The tiny 1/8" hole in the pan about an inch above the leg mount bolt (front of machine is to the right) should allow for enough room to use the original drain hardware and nut.

Position was chosen to keep location the same for front and rear. Not really enough room to move the drain hole out of the profile of the leg in the rear.

Looks like you are aiming to go through the pan right at the corner underneath where the legs attach, but not through the leg metal right?

I do not link relocating the drains that much will do anything bad on the machine, and its certainly a space that is not being used. One could argue that it makes the concrete slab stronger since its not thicker at the edges and does not have a long diagonal pipe running through it.

Cheers,

MIke’

The drain will go through the leg, not enough room in the rear to go around. If you look at the middle photo it shows the proposed hole just above one of the corner leg fasteners.

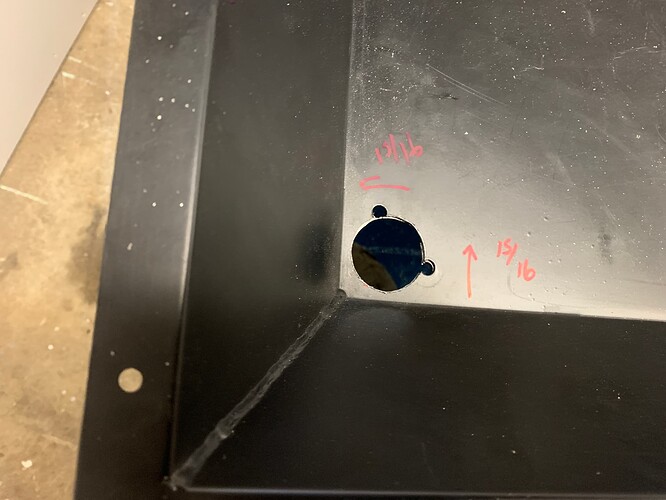

Already drilled lol. Managed to tuck it right in the corner. Used 3/4" tubing and cut up some through hull fittings foe the bottom of the drain.

Will send some more pictures.

Cheers

Mike

i moved the attachment bolts for the legs and put the drain tight as possible in the corner - that gives a straight shot down and minimizes how far to move the drain. It basically sits just inside the existing bolts, so those bolts are moved.

Here is the assembly - I am using a conduit bushing for a “strain” release and to protect the tubing. It will be caulked but given it will be encased in concrete anyways …

Cheers

Mike