My CROSSFIRE PRO suddenly cuts in places where it shouldn’t be cut, it’s as if it just doesn’t know where it is

What is it rinsed

Have you been successfully cutting before this happened? If yes, maybe one of your couplers has started to slip.

Yes I have, I’ll just check it out Thanks

it wasn’t clutches. I have tightened them and marked them so I can see if they are turning, and run a program and that has not fixed it. I can see my screen flickering once in a while when the plasma cutter turns on

What plasma cutter? Sounds like electrical inteference.

Stamos S-Plasma 85 CNC

That appears to be a high frequency start plasma cutter and is not compatible with Langmuir motion control boards.

can I insulate the water table so it has no contact. or is there nothing I can do to get it to run with it.

I’m not an expert, but Langmuir says that their table will not work with a high frequency start plasma cutter.

There have been reports of motion control boards being destroyed by high frequency plasma cutters. Most of those were cheap Chinese machine and probably not as insulated as yours, but it’s still not recommended.

The communication failure between Firecontrol and the table is a good indication that the plasma cutter is the reason for your problem.

which plasma cutter would you recommend that doesn’t cost too much since I have a plasma cutter I can’t use

The primeweld cut60 or the everlast are probably some of the cheapest option that seem to work really well on these tables

If you need cheap cheap the harbor freight titanium will work. You can search the forum some seem to use it. I believe the torch off is a little slow. Buy the best you can afford so you don’t cry as often.

Yep…

Sticking with your current machine… The juice isn’t worth the squeeze.

See this post.

Get a non HF plasma cutter. Maybe sell the unit you have to recoup some money?

As suggested. The Prime Weld unit is not a bad machine. I keep one next to my lift.

Keep in mind. If you do keep your current machine and use it for other (hand held) projects. That machine will still cause issues with electronics.

As soon as you plug it in its connected to your entire electrical grounding system.

Yo would have to install an RF filter on every outlet just to try to mitigate the noise created by the machine.

Thank you for your help.

I have been allowed to borrow this CUT 85CNC : PLAZMA cutter on Monday for a week to see if it can run with my CROSSFIRE PRO, with a view to buying this here https: //bourzougas.spartus.info/plasma-cutter/cut45pfc

Why buy a $ 1000 Eros $1150 us machine without any support? Buy an Everlast 62i for less than $900 and get support.

I was just saying. I know for a fact that it will work perfectly.

But the problem is that I live in Denmark and should I buy the PowerPlasma 62i in Europe, it costs around 1400 dollars

That unit claims to cut 25mm with 40 amps. It doesn’t list the material, but even mild steel I’d be skeptical 40 amps will cut 25mm.

I’m also skeptical about that, but I only have to cut 1-4 mm for the most part

how can I check if there is a signal on the burner switch cable to the plasma cutter when I turn it on manually from firecontrol, because it will not turn on the plasma cutter

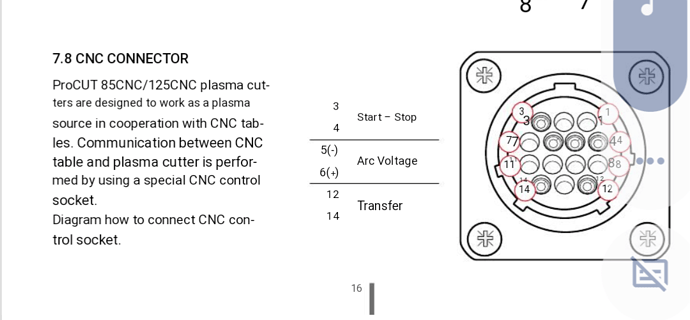

Do you have the torch on/off wires hooked to pins 3&4 on the CNC connector?

You can test the relay by checking for continuity between the inner pin and outer barrel of the torch on/off port on the electronics enclosure. If it is working correctly, you will get continuity(a closed circuit) when you press the torch fire button in Firecontrol.

You can test your wiring to the plasma cutter by jumping the inner and outer parts on the barrel connector with a wire or paper clip. Unplug the connector from the electronics enclosure and jump the connector at the end of the cable. The torch should fire.