I’ve got a 62i that’s going to be excommunicado from the XR… I think my expectations were too high… It works… As in it cuts, but the plasma delivery is not consistent. It’s running the IPT60 machine torch and consumables from George’s Plasma Shop.

Because everyone has a different idea of “good” … Here’s my definition of a good cut… Material example 1/8" mild steel.

*Near 90 deg walls on cut.

*Symmetry of cut, so circles are true.

*Minimal backside slag

*Kerf width consistency

I’m doing fairly intricate cutting and need accurate tolerance and repeatability. Intricate work means lots of pierces… Average pierce count before failing to meet above standards is around 200 in 18g mild and only 100 in 10g. That’s just not what I was expecting… I am using the same basic parameters in file creation… 0.8s pierce dwell. 0.12 pierce height. 0.06 cut height. 0.16 arc lead in and out…

One of the worst issues is the flame will diverge easily and contact the nozzle, resulting in torch exhaust angle from the burn out. I can see it happen, torch starts blowing green as it cooks the copper… Dry fire demonstates significant flame angle out of torch. I get 2nd arcs often… When these happen, failure is from blowback start piston favoring one side of nozzle and erosion balls up, shorting the electrode and nozzle together… Lightning show ensues. I’ve swapped the original machine “IPT60” torch for the aftermarket IPT60 machine torch from George’s… His functions a little better… Piston seems to be more consistent on fires. The internal wires size and sheath quality of the machine torch from George is notably heavier duty…

The Everlast 62i is on my XR Table… The XR is absolutely amazing, wish I would have put another Razorweld on it. I have absolutely zero issues with the Razorweld X45 on my PRO table. The speed, accuracy, and consumable life is superior. For comparison, I had 1400 pierces on the original consumable set that came with the Razorweld X45. Kerf widened out a little, so I changed out… 1600 and counting on the second set. Kerf in 20g started at 0.047 and is now 0.053. Never once have I had a misfire… Not once! It’s never second arced. The flame is always 90 deg and cut material walls are not tapered.

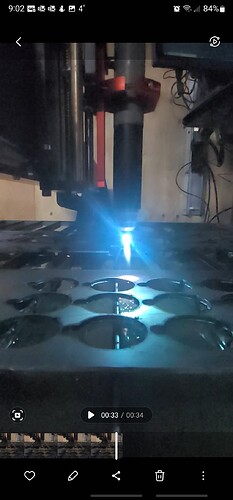

I finally had enough of the Everlast drama yesterday. I was trying to get through 50 2" circle event medallions out of 10g mild. 100 piercing points total, ate 6 nozzles. Blow outs were the problem… Incase you’re thinking I overpowered… I was running 30amps. 20 or so unusable cut outs… The ones I did use all required excessive time grinding edges. What should have been a 30 min cut and a few hours with Cerakote and engraving took the entire day and minimally met my standards for delivery.

I’m sharing this with you all to help guide your purchase plans… The Everlast 62i plasma machine itself is solid (loud) and tough. I bet it rocks with a hand torch and freehand cutting. Probably good for thick metal cutting that will require post cut processing. Consumables are cheap for it, so frequently changing them out isn’t the bank breaker.

I think the “62” being a bigger number factored into my mind when I was buying the Everlast. $1300 typical price… Seemed like a reasonable increase over the $995 for Razorweld CNC with X45 machine torch. What you need to remember is that even though you’re plugged into 220v on both… It’s not a straight comparison of 45 amps to 62 amps. The DC voltage delivered to the torch is different. Cutting power is better compared with watts (volts x amps). My Razorweld 45 gives 118 volts DC… That’s 5,310 watts. The Everlast 62i only deliveres 96 volts DC… 5,952 watts. That’s just over a 10% increase in available power… Delivery of the power is the second factor… The 62i just isn’t getting it to the metal cleanly and effectively. So don’t fall into the same bigger is better trap I did. Quality is better.

So what am I going to do? I ordered a Hypertherm 45XP for the XR just before posting this… I’m wishing I went that way originally… I know I’d be happy with another Razorweld. The Razorweld X45 is a great copy of the Hypertherm 45… And I’ve read only possitive posts about Hypertherm from the expert guys here… So I kinda want to try one out and see if there’s much difference between those two. I’ll post some Hypertherm 45xp VS Everlast 62i cut comparisons when it arrives.

Here’s what I was working on… Disc golf ranking tags for the local league.