Hey everyone,

I’ve been using my pro for a couple months now and was wondering if anyone has figured out if there’s a way to eliminate the divot on the backside of the parts where the lead in/lead out is located?

I’m currently using a Hypertherm Powermax 600 paired with a duramax retrofit torch using fine cut consumables. The cut’s are pretty clean with the age of this machine but I can’t seem to find a way to eliminate that divot on the backside if it’s possible.

Sheetcam Settings:

Material: 14G steel

Consumable: Hypertherm finecut

Kerf: 0.055"

Feed rate: 125 IPM

Pierce delay: 0.6s

Pierce height: 0.09"

Plunge rate: 100 IPM

Cut height: 0.06"

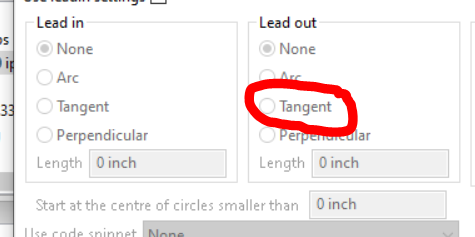

Lead in: Arc @ 0.125"

Lead out: Arc @ 0.125"

I’d appreciate any suggestions that may work! Thanks