don’t use that option… i believe its only for outside perimeter cuts to make sharp 90 cuts.

Yeah I had it clicked on “none”. Ill have to try “no lead in” when I try it again. Thats the only other thing I can think of that would cause the little cuts. Every picture I takes is too big to show here too haha

are you added a lead out? if not, then try it with one. not having a lead out will finish the cut where your lead in enters the outline instead of finishing in the scrap piece of material so it might leave a lil divot.

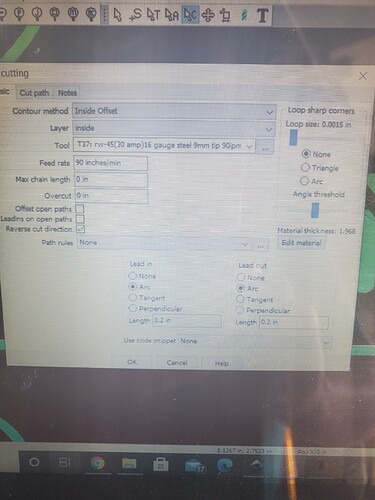

I have “lead in” and “lead out”… i just noticed I have “overcut” at 0.2 inches. Maybe that might be the problem?

could be… i don’t use that either on mine

Wow, I’m going to try that single layer method now. I wonder if there is a setting that lets it do that. That will save me some time.

OP, have you done any further tested with the changes suggested?

i don’t think there’s anything special on doing it that way… i just think it’s smart enough to put everything in the right place.

I think the overcut is what you want to get rid of… As the cutter passes your starting point, it’s going to be “looking” for metal to burn… And, it finds some so, widens your kerf for the distance of your overcut.?? Possible I guess… Good troubleshooting going on here!

I think it might e the overcut, I have the “overcut” at 0, I’ll try tomorrow and see if that helps.

I cut out a few more designs and I think it was the “overcut”. It seems to be working better now. Thanks for everyone for helping.

That’s great Shane!! Glad to hear it’s working out…

I never use overcut especially on small pieces that are going to drop. The arc tries to follow the drop or jump over to the main piece trying to finish the overcut flaring out leaving a divot.

I thought i fixed it but I’m still getting little blow outs in my lettering. I tried lead ins and lead out, no lead ins and lead outs. I dont know whats happening… theres no extra nodes or anything

showing in sheetcam or anything like that. Its weird.

show some pics of the cuts and your settings

show a pic of the cut path and turn off the arrows and kerf/cut width. does make sense that it’s still leaving the divot. only thing i can think of is to increase the lead in/out and/or use a tangent or perp entry/exit.

Hi Shane… So, I know you’ve said you’ve tried no Lead-ins along with all of this testing… I think no Leads would give you a divot where the initial pierce is made before cutting… AND if when you use lead-ins, they are from what I can tell almost a quarter inch in length… (.20) ??

This is a long shot…

Could it be possible that the pierce for the lead in ends up so close to the other edge of the letter to be cut that the pierce once again ends up close enough to the opposite cut line that it leaves you with a divot that way as well?? Looks like the letters are thick enough that this wouldn’t be a problem but, take a look at that as well…

I replaced the consumables and it all seems to be working well, im guessing i might have kind of ruined the old ones when i had it set to the hypertherm settings and cut a few small detailed things out, i only used a half of a sheet of 16 gauge but it still runined it.

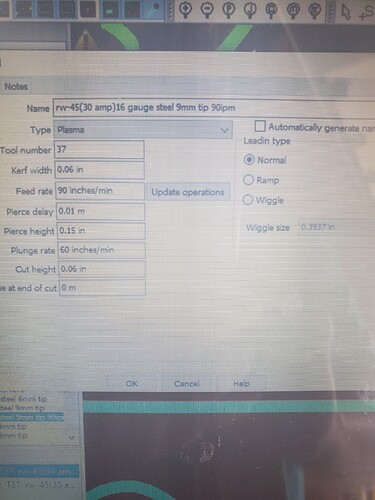

What are the units on your Pierce Delay? It looks like “0.01 m”, hopefully you don’t mean milliseconds, that’ll never happen. Is that supposed to be 0.01 minutes (AKA 0.6 seconds)?

yeah its 0.01 minutes, its the lowest it would go unless its 0.0, but people said dont have it at 0.0