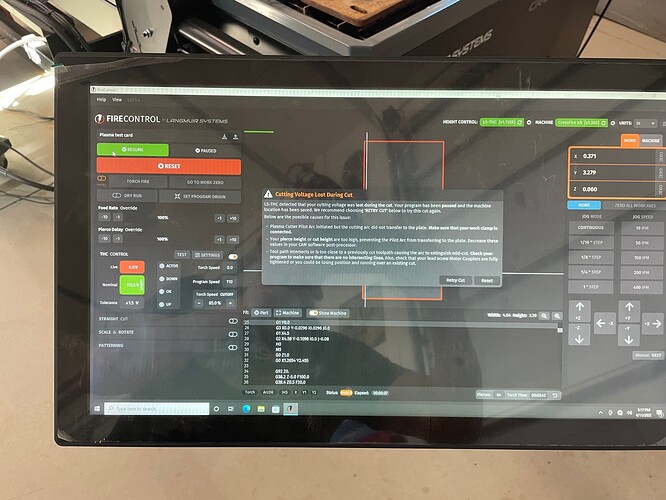

I keep having the same issue and have not been able to correct the problem. No matter what I try the same thing happens. I can usually get about half way through the cutting process when the torch stops firing and the program pauses. Any ideas would be greatly appreciated.

I am running a HTP MicroCut 875SC v2 plasma.

Do you have your material clamp on your material during the cut?

Sorry have to ask.

Does the torch begin to rise off the plate before it terminates, during the cut?

Your air pressure is being maintained throughout the cut?

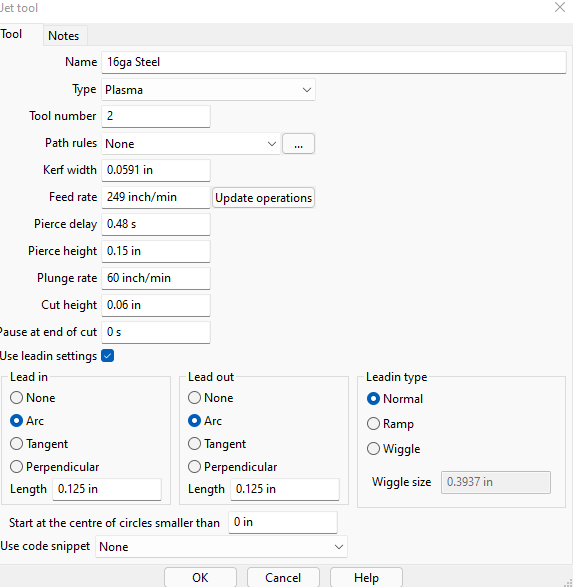

Your voltage seems decent what’s your cut height set to in the program?

And welcome to the forum

Thanks for the quick response.

Yes, I am clamping directly to the material.

No, the torch does not rise of the plate before it teminates.

Yes, air pressure is constant and clean.

The cut height is .06

Next pull your consumable pack apart ,inspect it thoroughly both for condition, placement and to make sure they’re the right parts.

Here is a link to the manual for anyone in the future that’s playing along.

Pulled the consumables apart they look great, I did find the contact cutting tip is 70amp. The replacement pack I have are 45amp. the manual shows them at 20-50 amp. I do have the cutting mode on CNC,

If you use the straight line cut feature in fire control will that successfully cut?

What are you cutting there at 110 in per minute? Is that 3/8 or 1/2 in plate?

What are you cutting and what parameters are you using?

Could you be running too fast for the material that it looks like you have on the table from the picture one your first post.

I was cutting 16ga and trying different speeds to see if that changed anything when I straight cut the same thing happens I get about half the cut before it looses voltage. a couple times when trying short straight cuts the torch would cut out half way and the program would still finish. The thick plate in the picture was used to weigh down 22ga that was a little warped.

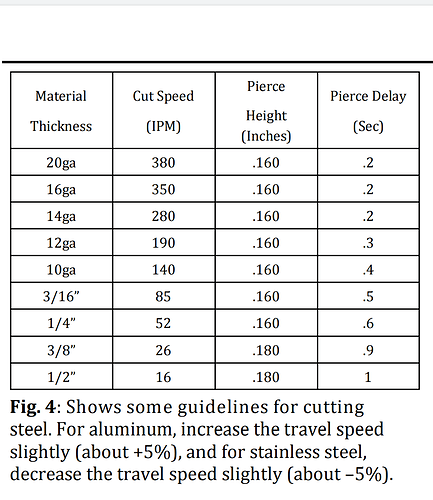

16ga parameters:

So in your first post the screenshot shows that you’re running at 110 in per minute what were you cutting then?

Is it always is the same amount of distance or time when it fails?

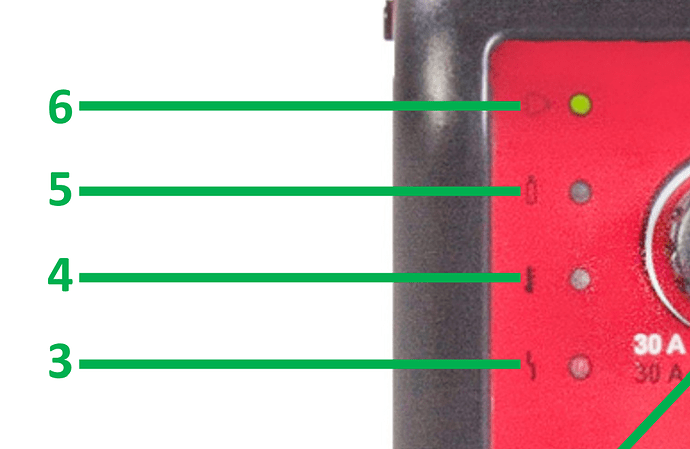

The next time you make a cut for test hit start and then wash the front panel up your plasma instead do any of these lights flash or illuminate for even a second when it stops?

I would focus some attention to scrutinizing the air volume do you have a pressure gauge very near the plasma torch inlet you could film while you cut?

What is the quality of the cut that is being cut?

Could you take a very good look at your torch trigger circuit again and make sure all the connections are tight.

Another long shot idea would be some pilot arc transfer issues with the HTP?