Without going into all of my settings, I have to say, for my first cuts, i was impressed. So i made several of these brackets which cut flawlessly. 14ga, minimal dross, i was fully satisfied…until i rotated the part 180 degrees to reduce waste. Then it cut really crappy. My question is that if i jogged the z axis and rezeroed it, before cutting this rotated part, would that affect my cut height with thc and ihs “on?” Tip looks perfect, i changed nothing in the program, just rotated, the program and rezored x,y,z. Z was still about .5" above part at zero. Seems like it was too high because now i have a decent bevel on this part.

Is the ihs light staying on?? It shouldn’t if so. Pictures of you z axis will help.

Rotating the part shouldn’t have any effect on the cut quality. The position of the Z axis doesn’t matter either, as long as it wasn’t touching the metal when you started the program.

I don’t know how many cuts you made, but moisture can destroy a set of consumables very quickly. What kind of air drying setup do you have? The moisture trap that comes with the plasma cutter is useless for this purpose.

I did notice, that it was on at the time.

It should only be on when the torch is touching off. You may need clean the z axis or check your wires. That is the reason it was trying to cut so high.

The lower plate appears to have a kerf width that has increased slightly compared to the top plate. That could mean the nozzle has excessive wear. It could still be a round hole but if you compare it to a new one, the old one is probably worn past the point of focusing the plasma stream.

Just getting back to troubleshooting…error cleared out fine. Noticed when i manually jogged z, there was a slight catch, maybe triggering the switch prematurely. Adjusted the eccentric bearings on z, and now that part works smooth, with thc off. I can make a manual straight cut just fine.

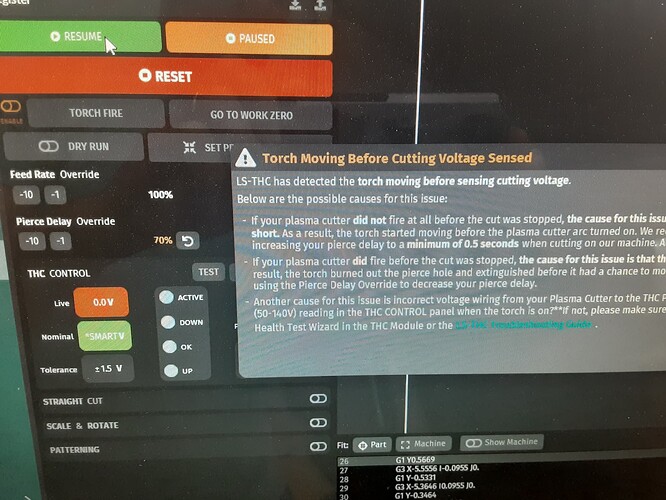

Thc on, i am getting the following error.

have you checked the recommendations in the error? what delay are you using? what is the shape of your consumables? post a picture of them for us to look at.

Update, working through the THC troubleshooting flow chart, and my voltage during straight cut is 95.0v. I wired the Cut60 divided because i didnt see anything pointing me to Raw voltage wiring. But frustrating now because in the flowchart, it says that they have experienced problems with Primewelds being wired divided! So now i am going to wire it Raw based on the flowchart. Am i on the right path???

i do believe most people have better luck being hooked up raw

Switched out consumables, adjusted piereced settings per error recommendations via firecontrol. Same results. I will post the actual value in a bit.

Again, I am very new to this…so hopefully I am making the correct adjustments in the right areas. Recap on equipment and settings (all has worked fine until I cleared the IHS error as mentioned earlier);

Crossfire Pro (I have cut about 12 parts to date, satisfied with all, THC working.)

Cut60-Divided voltage

F360 (trial)

14ga, 110ipm

Post Properties; CUT HEIGHT .059" (.10 measured during cut, decreased to compensate, didnt change), IHS SPRINGBACK .02, IHS-selected, PIERCE DELAY .5sec, PIERCE HEIGHT .15", THC-selected.

All cuts fine with THC disabled.

I would start by going raw on the voltage. For some reason you are not detecting good voltage. If you do a search for prime weld and raw voltage you can find where people was having issues and the discussed. May give you better insight.

Have you done the THC test in fire control?

yes, resting 0.5v, line voltage 0.0v. I will continue to search the forum. thank you for the insight.

the cut60 works just fine with divided voltage. i would up the pierce delay to .8 secs as that is the optimal delay i have found. anything lower and you’ll get intermittent firing issues.

I use Cut60. I never go below 0.7 because I have gotten the same error as OP when I do. It’s been mentioned in several posts OP, give it a try.

The recommendation for raw voltage on Cut60 was for the early (1st generation) units like mine. LS even temporarily took them off the “recommended cutter” list. If your CNC plug is in the lower right corner go raw. Upper right, divided is fine.