I would definitely try clamp on the material. Also to keep waste down find a small piece to cut as a practice.

Judging by the bevel of the cuts, it appears that your torch may be too far away. And the added power that is needed to cut when further from the material may be resulting in the destruction of your letters.

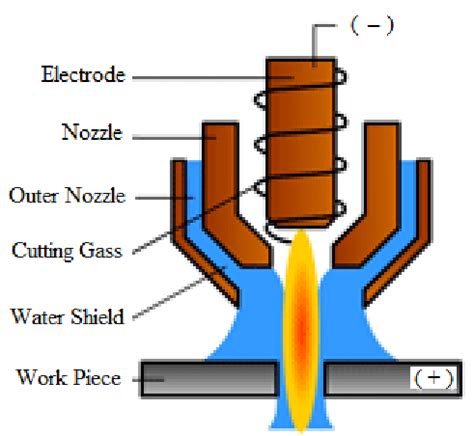

Edit: Corrected to say your torch may be too high. And, ignore the “water shield” in the diagram.

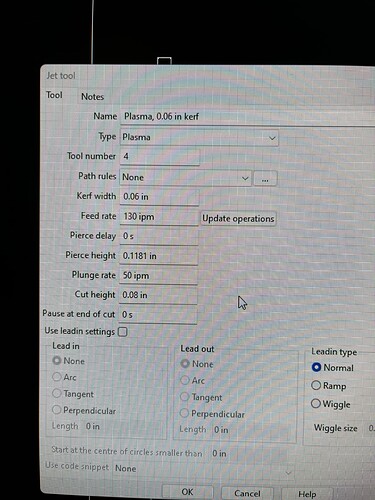

How is that adjusted in sheet cam ?

First off, you would want to confirm exactly what height the torch is during cutting.

- Do a test cut and while cutting, press the space bar while FireControl is running the cut. This will stop the cut, torch position and height.

- Measure the height between the metal and the torch with a feeler guage.

Then, if you confirm that the cut height is too high, you give a cut height smaller than you have been in the “cut height” setting of your tool in SheetCAM.

Will do. What is the proper ht anyone know have a razor weld 45

0.06 inches, I believe, will get you in the ball park.

But keep in mind, I would not monkey with those settings until you know that you are using the correct consumables.

I need something adjusted cause I have my lead in and lead out at .08 and I still see them in my cuts

These came from Langmuir with the machine

Yes. I saw that in a few places. Sometimes you can speed up or shorten you lead in to make it less noticeable. Others like to use a radius lead in versus an angle lead in and have success that way.

Many people advocate to eliminate the lead out. If you are concerned about getting a complete cut, you can CAM the cut with a “finishing overlap” of a micro amount like 0.02 inches [that is what it is called in Fusion - not sure the term in SheetCAM]. But, in most cases, you can eliminate the lead out.

So is your plasma cutter a Hypertherm or a RazorWeld?

If you are saying Langmuir sent you Hypertherm consumables, maybe you have a Hypertherm torch. That is possible. Or, perhaps there was a mix-up.

I am not comfortable giving input on changing your settings if there is a possibility that you have the wrong consumables.

If you have the correct consumables then definitely check and adjust your cut height. I have been cutting fine and all of a sudden my cut height is wrong and I am getting lots of bevel as well. I have not got back in the shop to investigate.

I have a razor weld that came straight from Langmuir with the table

Actually the older model 40 amp hypertherm. Look just like the rw45. I have heard of so measuring the and say they are the same.

A lot use the all the time.

I do pierce at .150 and cut at .06. also I always try to do a lead in and out that is at least double my kerf

Looks terrible

Can you take a up close picture of your nozzle and electrode?

At 45 amps you will need to go faster

@Phillipw - just asking: He has pierce delay set at 0.0 seconds?

I know with Hypertherm, we need at least 0.6 seconds, I need closer to 0.65 seconds. I am not familiar with other machines and SheetCAM.

@Jarett : definitely you cut height is set too high and is consistent with your slope on the cut.

I never even noticed that. With My rw45 .5 on thin stuff.

I also do the same.5 with my ht65 have never had a issue either.