Hello, I need to fabricate something out of 33gauge (0.010", 0.25mm) galvanized steel. Has anybody any experience and can share feed rates and plasma cutter settings? More or less, then I’ll have to fine tune for my setup…

be very careful of Galvanized steel plasma cutting…very…very toxic fumes…

clip from the web…

" Subsequently, question is, can you get sick from cutting galvanized steel? One danger of cutting galvanized steel is metal fume fever, a condition caused by the released zinc fumes. Metal fume fever comes with a number of flu-like symptoms that include fever, weakness and fatigue, aches, nausea and chills. Coughing is another common side effect, often accompanied by a dry throat."

Not recommended. Zinc gas expelled during the cutting process is highly toxic.

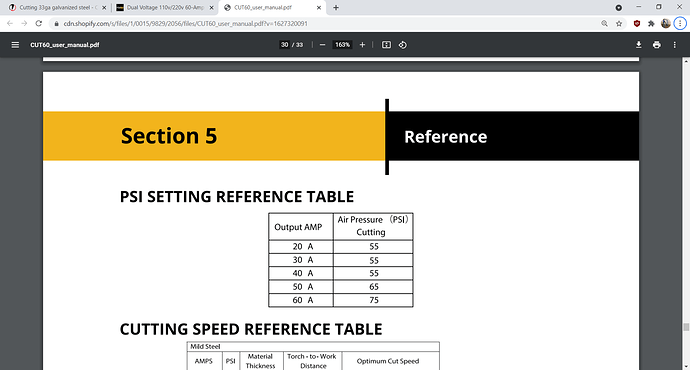

OK so I cut it but it was a bit of a challenge. I set the speed to the maximum, 7620mm/min (300IPM). Set my CUT60 down to 20A and 30PSI, the arc would NOT start. I had to bump up the pressure to 45PSI and 25A. Very strange? Why would that be?

Cuts are remarkably clean, even though I used pretty random settings

It’s not strange at all. Your air pressure was too low to blow back the electrode and start the torch. I’m surprised that it worked at 45psi.

You are absolutely right, I … don’t know what I was doing. As the material was so thin, I guess I extrapolated going way out of the range. This explains it all, now I know.

I had serious warping issues when I tried cutting it last. I was considering using it as prototyping material for testing new designs before cutting the thicker expensive material.

Mine came out surprisingly good. The water splashing underneath might have helped. The THC was working to keep it in the range as it was “moving” while cutting. Disclaimer, I cut a large area, about 24x36, to make a conical shape so I never localized heat too much, and I was going max speed.

A lot of the HVAC guys are using the 0.65mm/20amp and 0.8mm/30 amp consumables for cutting out duct work it gives them really fine cuts.

Oh that makes sense. I used the regular consumables that I use for 1/4" material

In the future I will stock in a wider variety of consumables.

I tried again at 20A 50PSI max speed (7620mm/min (300IPM)) and it’s perfect