Im back… again…

The good news is i’ve been using this thing nonstop and its paying for itself.

The bad news is, with constant use, I frequently encounter murphy’s law.

I originally assumed my cuts were beveled pretty substantially because my consumables were wearing or moisture issue etc etc.

After taking a closer look, I noticed by cuts were beveled in parallel directions on the X axis but cuts made on the Y axis are square.

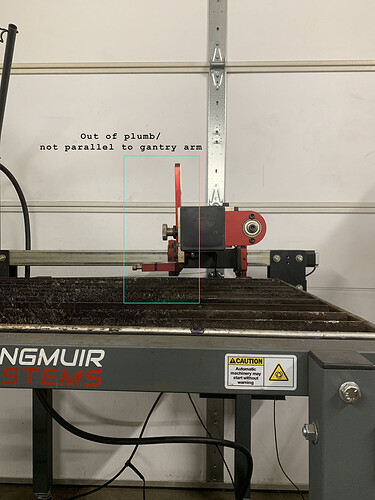

I looked at what could be the issue and arrived at the torch holder/carriage assembly is actually out of plumb to the table/slat bed, which may actually be because the X axis gantry arm is twisted in relation to the end that rides on the main assembly.

I don’t see an immediate means of adjusting this on the carriage or the arm unfortunately so I require some guidance before I just start making things worse with trial and error. I looked through the alignment videos and this issue isn’t addressed.

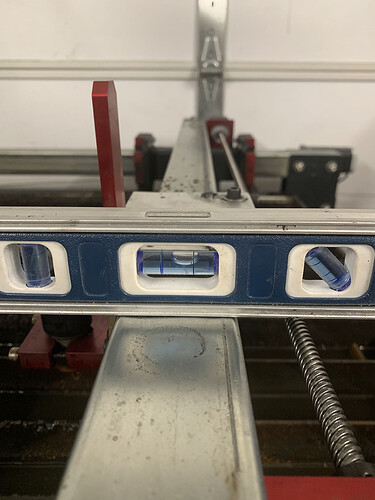

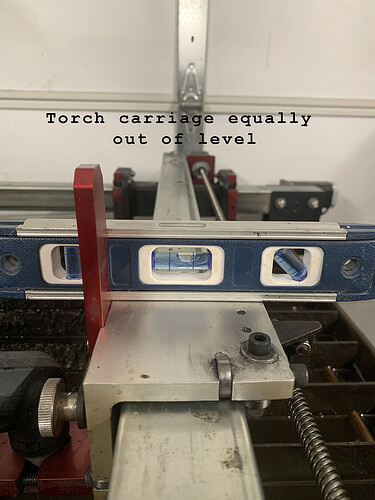

If you look at the photos, the gantry rails are level but the gantry arm itself is out of level, in the direction my cuts are turning out beveled.

Furthermore if you look at the torch carriage assembly, you can see a larger gap at the top than the bottom between the carriage and the gantry tube.

Hi @BrooklynBravest Thankfully the squareness is adjustable. Check out this thread and let us know how it goes:Torch square to table adjustments

1 Like

Fantastic. You guys really thought this thing out.

Thanks for the quick help as always.

I think the stock LS mount is terrible, especially with a machine torch like I have. It is super basic and offers zero adjustment in the interface between the torch/mount. I bought some of the mounts @Lil_Abners_Kustoms is making. What he designed and machined should allow for precise adjustment that won’t change as the torch moves through it’s range.

It’s funny you mention this because after making my first cuts the other day I noticed the same thing on my parts and then looked at the angle of my torch. You won’t notice the bevel on something thin (or something where precise accuracy doesn’t matter), but if you try a thicker material it is pretty obvious, especially if you cut any holes. The only way I can see in solving the torch mount alignment issue would be to use a better mount.

1 Like

How does the torch mount not have adjustment? You get a straight edge, check that your carriage is square, if not you adjust the adjustment screws and the bearings, and call it good. Should be a one and done deal. Don’t see how that’s a terrible design at all.

3 Likes

It is adjustable… Daniel posted it above.

I think the overall table is very well thought out. It isn’t going to be perfect for $1300. They have to cut corners somewhere to bring you the most affordable yet functional product they can.

1 Like

The only issue with the machine torch is the leverage it poses to the stock mount, thus the double mount.

I personally don’t have a machine torch and have it adjusted and holding well within a degree. Happy with everything LS has done to date.

4 Likes

I should clarify that the mount isn’t really the issue - it’s the clamp on the mount that holds the torch. The mount is easy to square up but the clamp is another story… And perhaps this mostly an issue with machine torches as the clamp is really designed to hold a modified hand torch. I’ve got everything level but there is no way to adjust the clamp that holds the tip of the torch (mostly toward/away from the gantry). My torch is held at a slight angle in comparison to the mount no matter what I’ve done.

I think a big part of the problem for a machine torch is that by clamping the end and not the body, it effectively creates a bit of a fulcrum point at the business end for it to shift since the torch itself is so long. I see absolutely no way to fix this without having a more solid clamp on the mount that holds the body of the torch - which is how machine torches are designed to be held.

Now for 90% of work maybe that’s fine, but I’m doing some precision cutting and I need the whole thing to be true throughout its entire range of motion.

Langmuir has done a great job maximizing the quality of this machine for the price point. It’s a fantastic value and I’m very happy with quality of everything overall. But it’s still very much a budget machine. Luckily all the areas they seem to have cut cost are easy to modify/change which is awesome. They definitely prioritized things correctly during development and designed it in a intelligent way.

For me the torch mount is one thing I’m going to change in a effort to improve the accuracy of my cuts because the stock clamp simply doesn’t work very well for what I have.

3 Likes

Ahhh I got ya. Ya I do agree that the torch mount that the one guy on here makes, would definitely be your best bet for a machine torch setup

1 Like

Update: Following the instructions Daniel posted I was able to correct this issue. Was a little bit of a pain took 30 minutes to really dial it in level.

1 Like

Have you adjusted the carriage left and right? Have found instructions for front to back adjustment but not for left and right. Front to back you press down on the red bar and make adjustments. Do you press somewhere when making the adjustments for right to left? We have a parallelogram bevel trying to resolve.

Kristi