Seriously, I hope something happens soon.

@Hoonigan (Dan) @langmuir-mike, Langmuir Systems would greatly benefit from better customer communication on roadmap. Perhaps it’s time for you to hire a community manager.

I don’t think I only speak for myself when I say, sentiment from your MR-1 customer base is growing frustrated with radio silence - especially in the context of a product that shipped with a some features that aren’t totally baked.

Customer loyalty and community goodwill are hard earned, and may be a bit less immediately rewarding compared to monthly sales conversions, but they will keep you afloat in the long run.

I 100% agree.

Radio silence does more harm than good in an age where we have an instant feedback loop in our pockets.

Having customers become irritated with your product and lack of communication doesn’t just affect those customers. Think back to the infinite wisdom of Wayne’s World. “They tell two friends, and they tell two friends”

An update that software development is in process, halted, or shut down completely would give customers an answer. While it would be disappointing to hear the software was k.i.a. it would quell the growing number of people wondering about features yet to be implemented or bugs yet to be resolved.

Hi All,

We always appreciate the feedback. We’ve been hard at work behind the scenes making improvements to a bunch of things related to MR-1. Below is a just a quick summary of things that have been completed/in the works for near short term release. We apologize about about the radio silence or any perception that we’ve forgotten about MR-1 because that is definitely not the case!! We firmly believe there isn’t a better bang for your buck on the market when it comes to CNC milling for metals; we have 3 MR-1’s in our shop that are almost running constantly making prototype parts for new products and shop tooling and it has quickly become our engineering team/machinists go-to machines for making anything in the shop.

- Improvements to machined components from vendors to limit QC inspection time and rework.

- Improved Touch Probe QC testing on a purpose built inspection fixture.

- Bug fixes to some Probe routines that randomly affect repeatability.

- Development of tooling and infrastructure to allow us to mass produce Epoxy Granite assembled base machines in our factory. We have now started shipping assembled units and this really opens the door to getting MR-1 into shops that don’t have time to put it together and just want to get it running ASAP.

- Instruction Videos for adjusting Tram. Every MR-1 machine can be adjusted to near perfect tram and it makes tremendous difference for surface finishing.

- Offering a Premium Limit Switch kit for those seeking even better repeatability (plug-n-play with existing wiring harness).

- Moving over to Fusion Coolant that offers better cutting performance and doesn’t stain parts.

- Offering an optional 5th larger coolant drain that sits behind the base plate. Assembled machines currently ship with this larger drain already pre-installed and it works great!

- Expansion of our cutting tool library including a better online store presence for finding and ordering tooling.

-

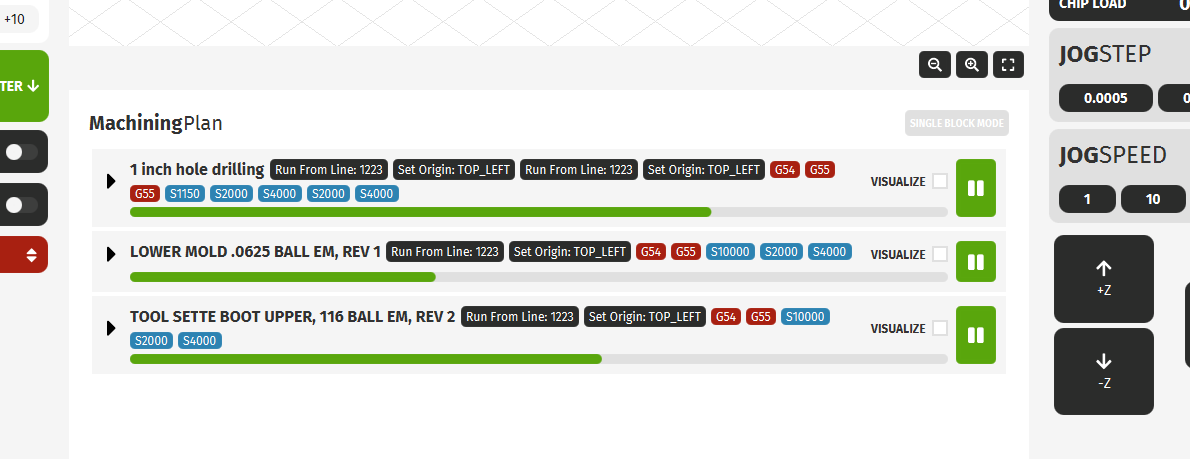

Implementation of the two most sought after CutControl features: Run From Line and Multiple Program Loading!!! The multiple program loading is going to be awesome because it will allow you to make (optional) tool changes in between programs that work off of the Auto Tool Set routines of the tool setter. Below is a quick screenshot of these features that will be releasing soon.

I never lost faith ![]()

Can’t wait for the improvements, keep up with the updates to make thus a more awesome machine.

Oh I have questions now!

S10000?

And Set Origin? Does this mean we could program a probing cycle into an operation at some point?

Any chance of an MDI (Manual Data Input) making it into a release?

Also, please see the thread I created on G and M codes. Some of the non functioning codes should be addressed.

Good to see an update though. Keep em coming ![]()

MDI would be great

A pre-processor (as I know GRBL doesn’t really want to do it) for things like variables, and maybe even macros/subs

I mean, I have a fixture that does 24 identical parts - even the ability to say “#101=-6.25”

And then later in the code be able to

X0.2672 Y[#101+.000]

and the further down

X0.2672 Y[#101+1.000]

I mean, pre processed we’d have

X0.2672 Y-6.25

and

X0.2672 Y-5.25

I just had to hand move a whole bunch of code over by .032. Not fun

(Oh, and M1)

I’d like to request a decrease in pop-up messages. I just ran a batch of 32 parts and I very quickly got annoyed at the “Program has ended” pop-up. All the other status indicators are already more than sufficient to tell me the machine is done running or is in standby, it doesn’t help that I’ve got coolant on my button pressing finger and now there’s two coolant streams running down my touchscreen.

When a home switch is triggered, I have to acknowledge the home switch trigger message, move the axis away from the switch and then acknowledge the message again when the switch deactivates.

Change the touch-probe routine to eliminate dragging the stylus across the part. When using Corner or Boss routines following each of the fine touches the Z axis is retracted while the probe is still activated against the part, dragging it off.

Add canned cycle functionality, specifically drilling cycles.

Post/publish all the currently recognized G and M codes for those of us that need to write our own pre and post processors. As it is right now I have to search these forums to see if a specific code is currently implemented or is at least working.

Add Distance to Go as one of the DRO displays.

Is Spindle RPM able to be displayed as actual RPM or is only commanded/programmed RPM able to be displayed?

Add Feed/Speed/RPM override sliders.

Enable chip load calculations to read tool parameters from the program for auto flute selection.

Another frustration of the pop up windows is sometimes you’re supposed to press the red button and other times the black one. Makes choosing the right answer and developing muscle memory way more difficult, slowing everything down.

I’m really curious about this @langmuir-mike . I had a limit switch failure shut me down this weekend. Turns out it’s really gunked up on the inside so I’m going to clean it and try and get going again soon. Can we get some details as to what the limit switches will be and if they are more coolant resistant than the o.e. ones.

Thanks

Any update on when the new cut control software will be released?

I’m starting to think I should do a controller conversion the way this is shaping up.

I have zero regrets with doing my controller conversion 3 months ago.

How about increasing the travel speed for boss/bore probing operations. I frequently machine large diameter aluminum bar stock (10") and the probing routine takes forever due to the travel speed between sides. Just a thought.

Please fix all the bugs before you implement anything else. Stop forcing the reboot of Cut Control every time a safety is set

Rufus, You have something failing that has no showed its face yet. I use my mill everyday without any problems. Now I did have limit switch problems till I changed the out to the button style type. My CutControl does not freeze up and all my probing operations work as normal. I truly sorry you are having so many problems. I take it that the stepper controller didn’t solve your problem?

Now, I am going to bore a 3.5" hole in my concrete next week sometime to add a drain behind the base plate. Just waiting for a epoxy kit to arrive from langmuir.

I’m not sure if it’s the same in your case, but I’ve had a few times where an alarm caused the ui to become unresponsive. I was able to use the soft reset inside of the software most of the time, which still requires homing the machine again.

I’ve also been jogging using the touch screen and had the ui become unresponsive and the “button” on the screen is still colored like it’s being pressed.

All together, while those times are a bit annoying, they haven’t happened really often or during a programmed operation. But I do hope if it’s a software problem it will be corrected in the next update, whenever that will be.

Skipshift you are on it. I have had the same issues but mine is more often then not. Every time you hit the safety, a lot of times when probing, and like you said when using the button on the screen. If I use this machine for 3hrs I have to home it half a dozen times and then you are scared of repeatability.

Hi John, I am extremely frustrated so in no way is this aimed at you but I don’t believe this machine is worth what I gave. Had I known I would need to spend another 2k to make it work I would have passed. Look at just this page there are guys completely converting the controller for some reasons. The limit switches are literally .50 cents (garbage). Didn’t you also change out the drivers?

I had to put together 3 remote pendants to make 1 work.

I went to home the machine 2 days ago and the X axis started screeching and beating the side of the gantry so I e-stopped it only to see the arm fell off of the switch because they are so cheap.

I am skipping steps on the motors and I am using the softest feeds and speeds I can think of. I am down to 8-10ipm with .050" deep cuts. These are less than half recommended numbers.

The worst thing is that Langmuir’s support sucks. Jake is an extremely nice guy but this has been going on for months now. I am in customer support for a large company and could not imagine one of my customers having to deal with this garbage. I don’t have the time and quite honestly I did not expect another R+D project. I have tried to go thru hundreds of Youtube videos to figure some of this crap out and I’m over it and really don’t know what to do. I have ordered extra’s so I can only pray they will make a change on how this thing runs.

I am very thankful for you and a few others on here that have helped but this machine is much less than what was promised!!! I suppose if I was cutting butter in all my projects I would be OK but I am not.

Trust me when I say I could go on. I hope the new holes you have to drill in that expensive epoxy because the drains are garbage works out.

Again thank you for the help you have provided to me as I could not have gotten this far without you.