Good afternoon,

This is a few days late as the official download for CutControl 25.1.2 released last Friday, but I wanted to make a post here to highlight some of the new features that were added to CutControl.

The first big feature that we added was Manual Data Input.

Manual Data Input:

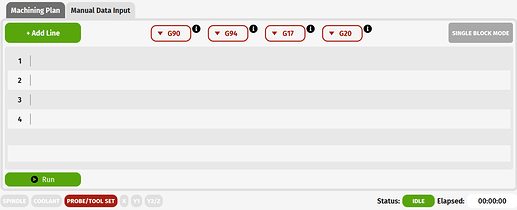

Shown here will be the new Program tabs, with Manual Data Input being the second tab. This will allow for the manual creation of small programs.

On the top line there will be the four safety line parameters these will be automatically included in every program that runs through the MDI tab. There will also be a M30 at the end of every program as well.

By selecting Single Block Mode you will also, just like Machining Plan, run each line separately. This will be ran just like a regular program using the Start Button on the top left.

The second feature that we added is the alert bar.

Alert Bar:

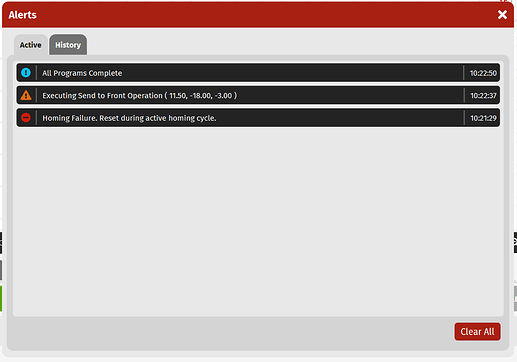

This feature will populate with the most recent alarm that has been triggered, or any alerts such as a program being completed or an operation is started, like the Send to Front Operation.

This bar will be accompanied by a new popup that you can access with the up arrow on the far right of the bar.

This Alerts popup will both have a currently active alarms tab that can be cleared, as well as a History tab that will only clear when CutControl is closed.

With the addition of this feature it has allowed us a way to alert the User to alarms without popups, so if desired you can suppress these popups using the new popups menu in the menu bar. Any popups suppressed will still populate to the alert bar, and if needed, stop the machine.

There are also other additions such as Auto Tool Set Safe Z-Height as well as a few much needed bug fixes.

Here is a link to the download as well: CutControl 25.1.2.3

If you have any questions about the update feel free to ask below or reach out to support@langmuirsystems.com.