Just got the XR up and running a few weeks ago and now able to start playing. Paired with

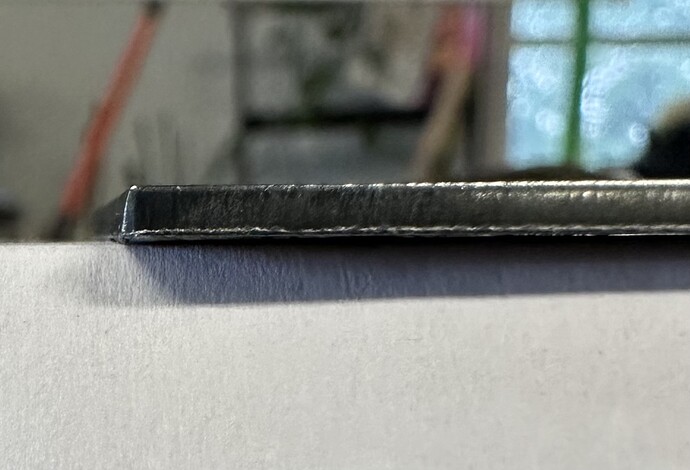

hypertherm 65 sync. Cutting some 16ga hr and edge looks decent. Question is what should I be expecting for a bevel? I cut some test squares with fine cut consumables at 40amps 90ipm .12 cut height is pictured below. Bevel looks to be about .007 a side. Measured with in .002 accuracy at the top of the cut. Just looking for opinions.

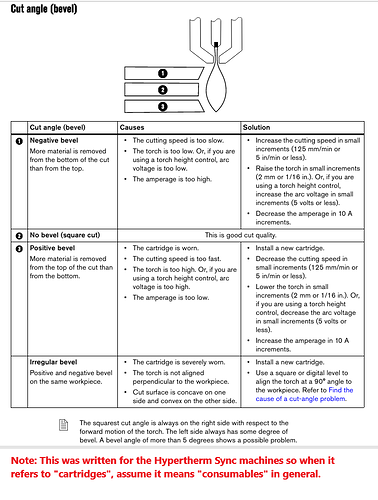

Based on your pics, I’d consider that your cut height is too heigh. I’d try lowering your cut height by .020" and see how your bevel changes.

I have also had a bevel like that when my nozzle was starting to wear. Compare a new nozzle to your current one. (And I coincidentally have Hypertherm 45XP).

If the orifice looks larger on the old one, swap in the new one. If it does not make any difference, swap it back out…that is not your issue.

Agree with Terrance that the torch being too high is likely an issue.

I reluctantly show this image: Brownfox has given tacit approval ![]()

Edit: I see that the OP has changed in this thread. Sorry Mike @FSFI. (Gary has the Hypertherm 45XP) I see you do have the Hypertherm Sync so you won’t be able to just swap out the nozzle. But that could still be the issue and it would cost the entire cartridge to fix it, if it is indeed just the nozzle. Same advice would be to swap out the cartridge and see if the bevel improves. If not, swap it back out.

Gonna check consumables and try to dial it in. Thanks for the chart!