Explain why wood and other products are being hyper inflated? Its not necessarily a tariffs issue IMO. The biggest excuse Im hearing is lack of truck drivers, which boggles my mind. We have plenty of illegals here now that might want the job! There are so many jobs available its crazy. All my steel is USA and rarely some Canadian. Almost every manufacturing arena was open all last year and this year, but all the sudden we have nation wide shortages of the dumbest things. I got 4’xs the orders last year and still into this year. All my customers seemed to have had work. Something just isn’t adding up. I called a place today where i usually get my 18g. almost 200$ a sheet. For kicks I asked how much for 1/8 and he said 389$ for a 4x10. I told him I get 4 sheets of 4x8 for that price and thats waaaay more than I was paying in December. But whatever reports you are hearing, hope its true. Lots of people being effected by the wood and metal fiasco.

Im really hope there isn’t issues! Im literally just finishing up some shop upgrades. Time is none so its been taking months to do the smallest thing. I got my other PRO hooked up and jogged. I got my Screw compressor hooked up. Now I have to bring in my other 80g and hook it up, run some more wire and I can have both machines running at same time. I can just barely fit the XR and a PRO in my one cut area. I don’t need the big platform at all really, I just want to see if the speed and accuracy will be better. I do like the added features too. I’ll basically only get a month or two use outta my dual setup until XR arrives then I’ll have to find time to set it up. Not sure if I’ll sell my other PRO or not but I will be running dual machines.

Lots of reasons. We live in a just-in-time production and delivery world now. The stock you see in your supplier today was raw material just about one production cycle ago (for example lumber takes about 3 months to go from tree to finished boards - the 2x4 you’re buying today was standing in the forest in Feb).

For lumber it’s because of supply not meeting demand since the 2008 recession. Sawmills got burned back then with extra supply and ratcheted back production. The demand post-2008 did not catch back up until 2019 and sawmills didn’t just run out & expand. Prices slowly increased over that time with production slowly increasing as well.

2020 demand skyrocketed. People stuck at home and not spending money started doing millions of home improvement projects. People who found they didn’t need to live near the office anymore started looking for houses elsewhere. People living in cities found that wasn’t a great idea when there’s a pandemic and started buying houses. New house construction exploded. People were willing to pay more to get out of where they were. Lumber demand outstripped supply. New sawmills aren’t being built because no one wants to take 6 months or a year to build one and then have demand crater. They can sell everything they can make at high prices, why take the risk to build more production capacity just to drive prices down and possibly end up with an idled mill when the demand drops?

Then Texas had an ice storm and shutdown the state for 3 weeks. Guess where 40% of the chemicals that make the glue used in plywood & OSB comes from? So sheet goods production is stalled. Then the refineries get restarted (takes weeks, not just flicking the switch to turn everything back on). That then allows the chemical processors to resume operations (more weeks to restart). Then the sheet goods factories can get the glues and make the plywood.

But there’s a shipping container shortage worldwide because we’re now buying more stuff than ever from overseas (regardless of what country you’re in). But ports and ships are operating at reduced capacity due to distancing requirements. Takes longer for a container to get filled, shipped, unloaded, cleared, emptied and returned to availability. Oh and don’t shutdown or slow a third of the world’s container shipping for more than a week by closing a canal or everything will back up and take longer to get back to where the container can be used again.

And that’s repeated for just about any product you want to mention. Those “illegals” aren’t gonna be new truck drivers because they’re illegal. The legal immigrants aren’t either because you don’t get to be a truck driver by showing up & saying you can drive. Truck drivers were already an issue with regulations cutting hours so they’d stop crashing as much and young people not going into trucking (seems like they like having a life that does not mean being on the road for weeks at a time away from friends and things to do). So the driver workforce was already aging. Pandemic came and they started retiring early or found something else to do. They’re not coming back. So it takes longer to get stuff anywhere at the same time more people want stuff delivered to their door from far away.

Steel? Same thing. Imports cratered due to shipping logistics (see container issue above), tariffs made foreign sourced more expensive or prohibitive and mills shutdown due to labor issues. U.S. mills are finally back to pre-pandemic levels. But other countries aren’t nearly as far along in terms of recovery - you know, people dying, no vaccines, watch the news. They just announced the rollback of tariffs on steel & aluminum from Europe yesterday (remember, everyone was our trade enemy so we needed to stop them from sending us stuff cheap). You might only use U.S. produced steel, but where did the ore come from? Or where do you think the folks here who used to buy steel from overseas get it? They didn’t leave your supply alone because they used to use China supplied steel, they switched to whoever could supply it. The price & demand went up while supply was down.

Every single thing works like that. The world’s automakers can’t make cars because there aren’t enough chips. The pool guy isn’t going to be able to take care of your pool this year because chlorine is in short supply (there are only 3 chlorine production plants in the country and between skyrocketing demand for antiseptic wipes and a fire that shutdown one of those plants they’re not able to keep up).

We could build lots of new plants for lots of production but do they get finished in time to make a difference? Can they be built profitably with materials prices the way they are? Will current prices and demand remain so it’s worth building? Or will things gradually return to pre-pandemic demand levels and all those shiny new production facilities are sitting unused because now there’s an oversupply?

That’s the explanation.

James, all due respect you lost me at watch the news. I don’t subscribe to fear mongering lies. Look up death rate in america last 5 years. 2020 was no spike in rates. Iv been exposed to covid many times, know many people who got it. The propaganda has many blinded. If you don’t watch the news you wouldn’t know there was a pandemic, period. Its destroying waaaay more lives than it took (if you can even believe any of their numbers). Really not the time or place for this convo, I can tell we do not see eye to eye on this. I understand demand in some areas are high and trucking is prollly overloaded. But there are alot of businesses that need workers and people just get paid more to sit at home on fat unemployment checks. Free money isn’t the answer. Tariffs IMO need to happen on alot of stuff, ESP steel. There is plenty of incentive to manufacture here in the states. People want to make a fuss about the coal and oil and global warming but will buy everything and anything from china. The biggest polluter of them all. Im not opposed from getting global things, but its been way too uneven and hard for americans to compete. Iv seen it happen to industries first hand.

This topic really turned. Lets stick to plasma cutting and leave all the other stuff for other forums. I come here to relax and talk about my plasma cutting hobby. I put my deposit down on the XR and have never owned a plasma table before. I have the best wife in the world for allowing me to spend 8k on my hobby.

I cannot believe I missed the $1000 off…This table is awesome, and at the current price point, a fantastic deal. Looks like I better start cleaning up the Crossfire Pro.

You’re right. Not the place for a conversation. You asked a question, it was answered, you don’t agree. That’s okay.

Muted.

I’ve heard there are viewpoints like this, but I thought it was a hoax.

I don’t come on here to get side tracked either this isn’t FB which I can’t stand. Plasma cutting involves cutting Metal. So the future of being able to get it is a big deal. I buy 2,000 lbs every 3 weeks. Its also pertains the future of someone wanting to drop this much money on a machine. I was at a crossroads my self. Should I save my money bc Im paying 2x’s the cost of steel I previously was and some places way more than that. Or would one risk it? Im happy LM is growing during all of this.

Wait a minute… You are saying that a lot of interrelated events caused a change in production, transport, and supply, while an increase in consumers with more time created an increased demand? Well answer me THIS, smart guy: what are your recommended settings for cutting 1/4 inch brass with a Hypertherm 45XP with finecut consumables? Cheers!

So… More on the XR… wonder how it’s shipping? Is it a bolt together kit like the pro or fully assembled. Wonder if they’ll offer onsite training like some of the other companies do ?

It is a bolt together kit, but they do offer a fully assembled option that cost $1495 and you have to pickup at their location in Texas.

This is from their main site under the options when checking out.

“Full assembly of your XR. Local pickup only from Conroe, TX.”

Freight. That’s why it’s not available for international sales.

Maybe its that Joe is giving away money and the rich see it as a chance to jack prices up to get some of it from the common folks. Its about everything that is going up. And they will drop the price down so its still alot higher than it was before the increases and people will just eat it up how much it went down but are still paying more than before the … …

I have been watching LS grow and have been waiting for a 4X8 table.

I watched the countdown to availability and pre-ordered right when it went live. I am very excited to add the machine to my fab shop.

Im going to inquire about the pallet size and breakdown. Most people don’t have a forklift or even access to one. so shippers sometimes have liftgate option for more money but not always. Also Im sure there is a diff in the truck size. Not all freight ships via semi but that will definitely be some logistical things we should be aware of.

Main reason softwood is so expensive is that the Europeans (UK, Denmark, Netherlands, Belgium, Germany etc etc) subsidize softwood burnt as pellets in their coal plants to the tune of high double digit billions a year… Even though it emits way over twice the CO2 of the worst coal per kWh generated and lots of other stuff too, they call it “CO2 neutral”… They are outbidding construction lumber every single time. The English even set up their own lumber company: https://www.draxbiomass.com/ Our southeastern wetland forests are being cut down, and permanent flooding conditions are the result (because of “climate change”,naturally)… all “for the climate”.

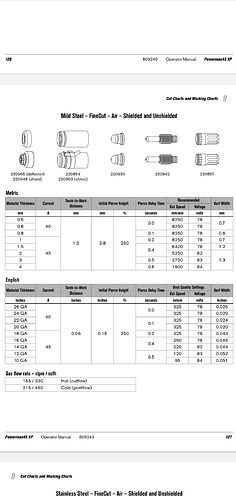

I wouldn’t use the fine cut consumables for that thickness of material(1/4" brass)

The cutting charts only go to 10 gauge.

Standard 45 amp consumables ran at 75% of the mild steel IPM would probably be close off the cut chart to start.

It was…umm, a joke.