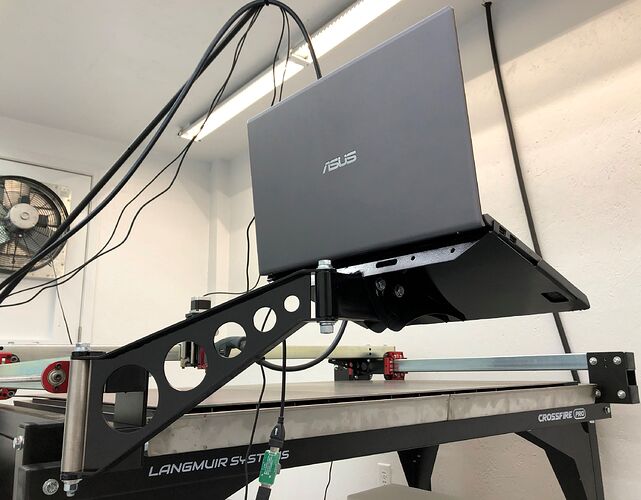

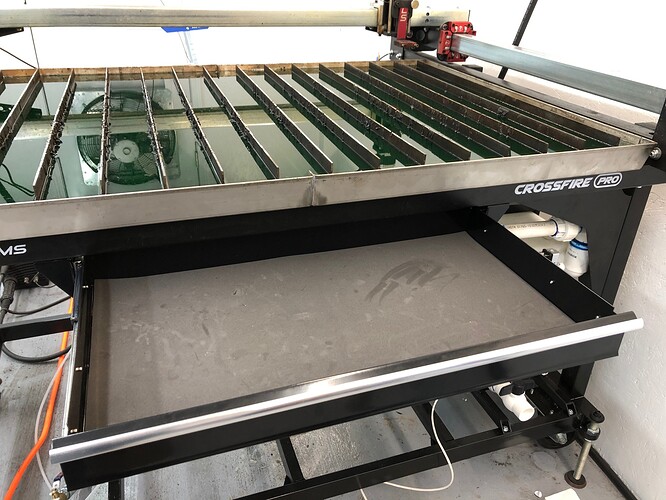

First project with the crossfire pro. No where near perfect and mostly made out of scraps but should be better than the carboard box my laptop was setting on.

Uploading: IMG_1104.jpg…Looks pretty good to me. Happy cutting!

Welcome,

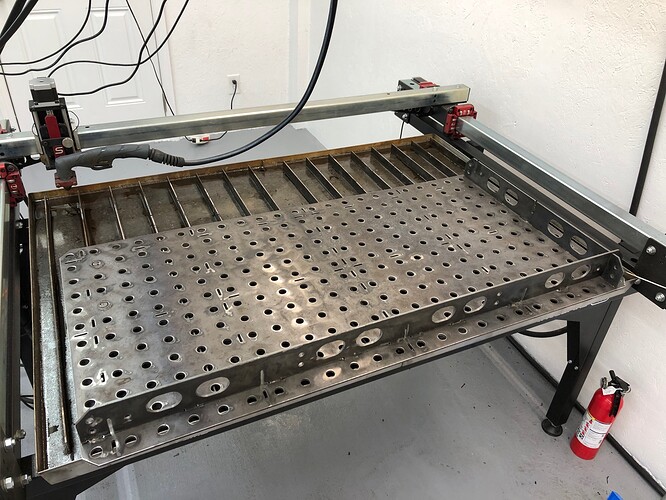

Looks good, now get the plasma cutter out from under the table.

Little bit of rattle can black makes it blend in. I’m thinking of making a shelf under the table for the coolant tank and plasma cutter with splash guard.

240 volts and water don’t play nice with each other.

Unless you only cut small stuff like 12x12 in the center of the table, your cutter will absolutely get drenched at some point. If you’re able to come up with one hell of a splash guard post it up.

I debated enclosing the bottom partially, but I want the air flow to the cutter.

Yeah I’ve already had the pleasure of experiencing “the mop” from cutting to close to the edge but fortunately it was on the side opposite of the plasma cutter. I bought a 4x8 sheet of 20 gauge stainless steel for making some splash guards but if doesn’t work, plan b is to mount the plasma cutter on the adjacent wall up high. I’ll post some pictures once I finish designing them.

I love how clean your area is!! One day ill have a nice space haha

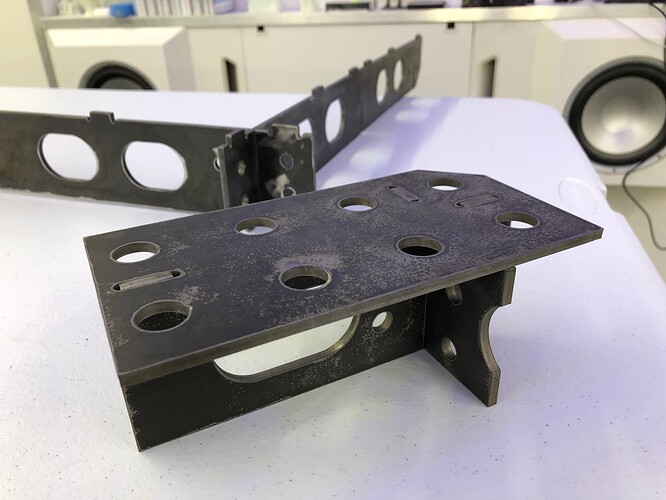

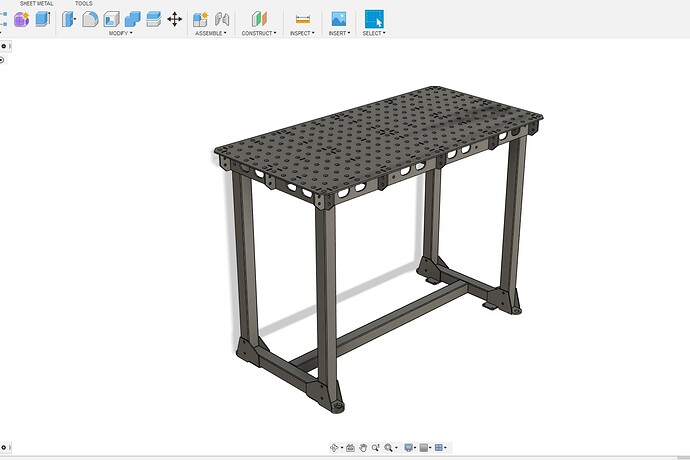

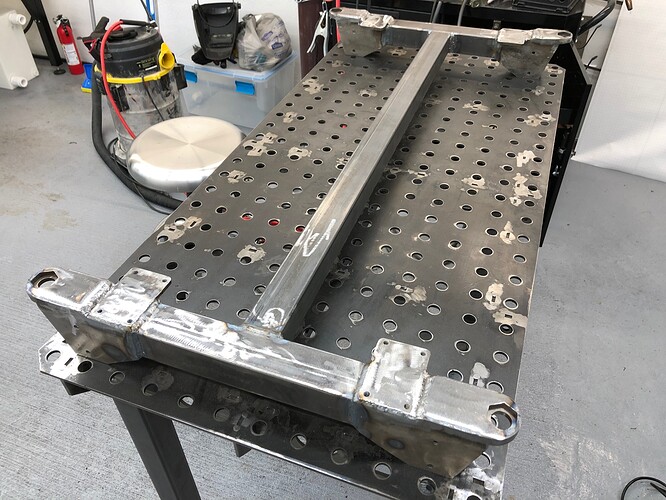

2x4 3/16" certiflat-like modular light duty weld table project. I’ve got some side & back right angles & wings, vice mount, clamps and jigs in the works for it after welding. First picture is a test coupon for measuring and compensating accordingly, this turned out to be a joke later since the consumables wearied so much through out the entire cutting process but it was a good attempt.

nice looking table build. Would be great for a low-volume user like me

I think you’re right, Jim. I think you should build two!

Ideally, I would like to have a 4x8 certiflat table but thats not in my cards due to my tiny work shop and budget. TomWS read my mind; i figure i can always add on or build another if i find a project exceeding the current size

With any of the Crossfires, you can cut something larger than the table in one direction. So, for example, if you wanted to make a Certiflat table 24x48, you could cut that on a 2x2 table. You can segment a design into subsections and then do a thing called ‘indexing’ to cut one subsection, then move the plate, align the plate/gantry, and then cut the next subsection. It’s certainly easy to match within 0.050", but matching within 0.020 is possible. Factor those tolerances into the Certiflat slat slots and you’re good to go.

Search the forum for indexing.

And, yes, I DO read minds, but don’t tell anyone about that…

And to clarify, I didn’t want @jamesdhatch to build two for himself. One of them is for me!

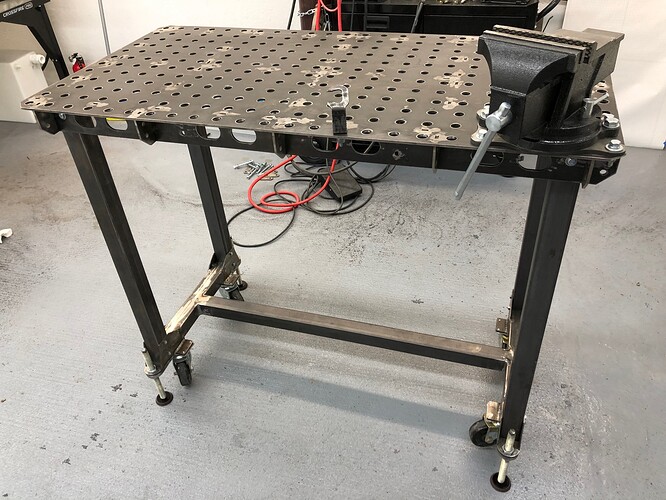

Well its nothing to write home about given my gnarly welds and weld spatter but here she is before paint. If anyone was curious, I got the flatness less than .005" with the clamps but after welding its more like .020" over 48" with a hump in the middle. That kills the precision machinist in me but should be fine for welding and such. There will a fixture rack or two going down below so it shouldn’t look like a daddy long leg for much longer.

Nice job. Any idea how much it weighs?

Couldn’t you cut a spacer for the middle. Use a clamp to pull the 0.020 down and weld the spacer from the center rib to the table to pull it out? Or use a BFH and give the hump a love tap?

Nice work by the way!

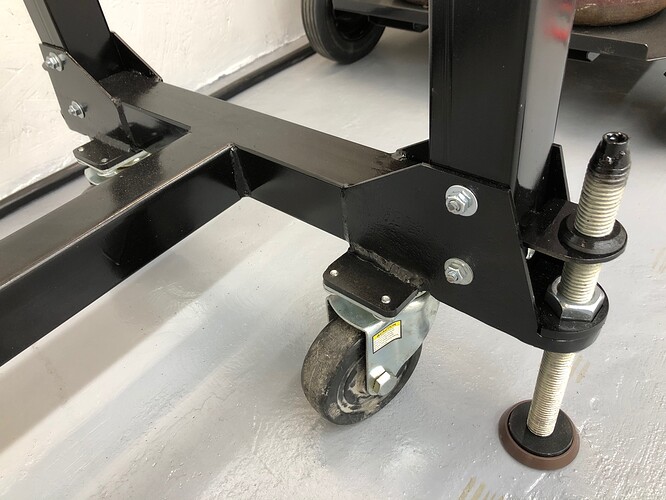

According to fusion 360, 142lbs so id say add another 15lbs for casters, leveling feet and hardware so 157lbs total. Its surprisingly rigid as is but once i put the racks underneath it will stiffen the whole thing up even more.

@Maleybr. lol that is actually a pretty good idea. For now im just going to say the .020 proud in the center is intentional to compensate for deflection when fully loaded… sigh

Great design. Even threaded the plate for the mounting feet. Nice.

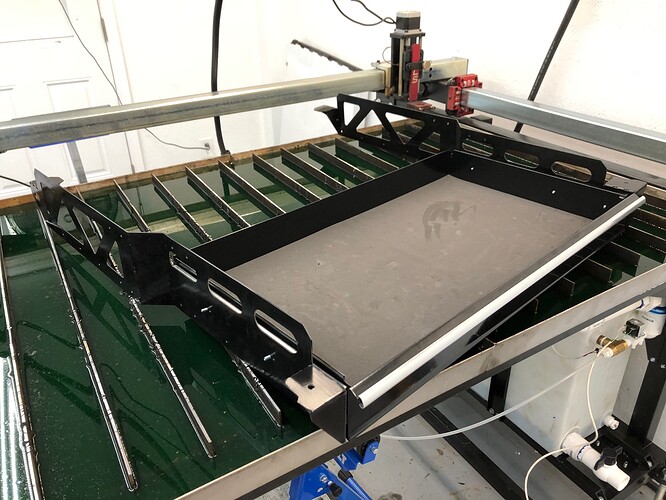

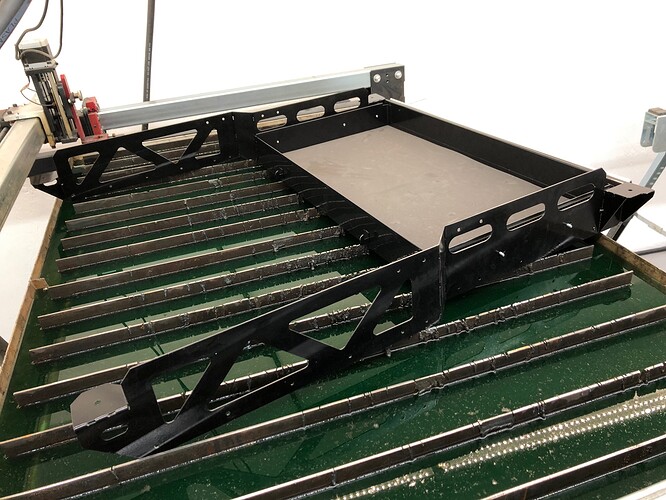

I’ve always thought that a drawer underneath the table would be a good idea for storing consumables, relative tools and such. So here is my take on one. And yes, it gots some sway with the drawer fully extended but other stuff will be bolted on the sides of the mounts for stiffening eventually. Also, there is a sneak peek at the automated coolant system ![]()