Great projects and nice upgrades. I really like the idea of adding a drawer to the table. Did you make the drawer itself or did you source it from a commercial tool box?

Sure did; the drawer came from a harbor freight yukon 30x18 tool cart that Im converting into a mobile deburring station and didn’t have room for it anymore. Kinda hacky but it works

Care to share what you found? Did your slots end up too small for the tabs with the used consumables? Mind sharing the fusion file for the test coupon? I want to start using slots and tabs but am lost where to start.

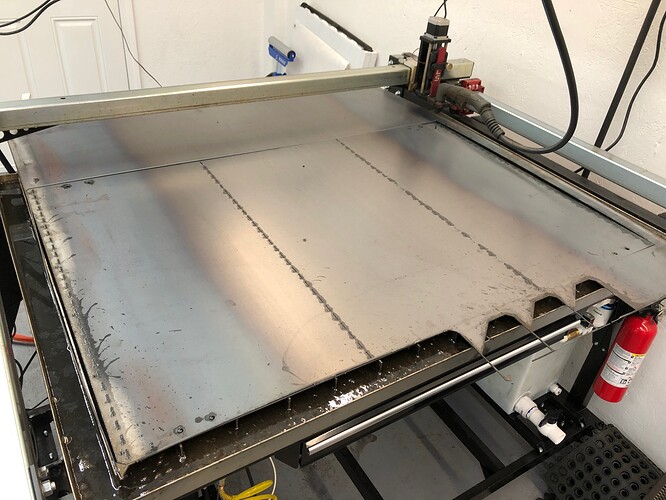

Table looks good.

Thanks

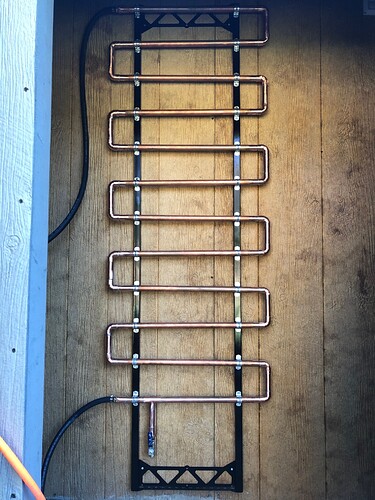

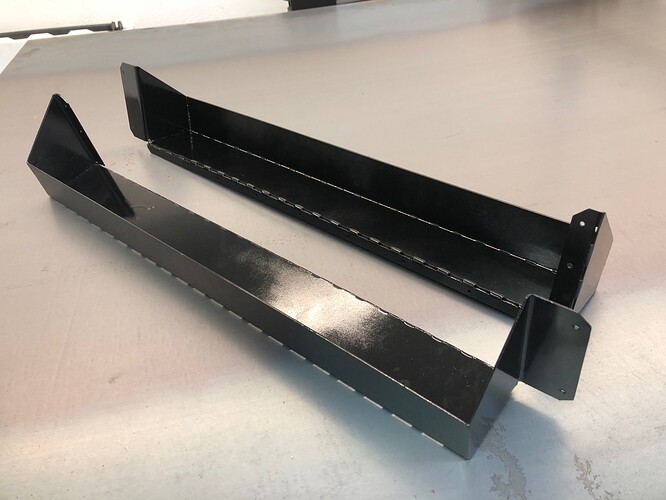

I want to re-attempt this table as a couple mistakes where made and to do a proper write up on the process. But to put it simply, I should have just added more clearance in the model for the slots as a good number of them had to be filed to size manually. Also, I would buy a magnetic base drill to do the 16mm holes as they need to be round for clamps and fixture locators. The program took roughly 50min to run with over 200 pierces just for the top so I was really pushing the x45 at 45amps for that long. I would definitely recommend breaking the program up into parts and letting the machine cool down between runs. At the time, I hadn’t made my air cooler yet so that didn’t help the consumables last as long.

I like it. I’ll be adding a drawer to my table once I get caught up on some other projects.

Wow! Great thread. I’m in  With leveling feet system…

With leveling feet system…

Mobile deburr/down draft cart project progress. Due to limited space and cnc cutting area (without indexing), this was my solution to reduce the grinding mess around the shop. Its made out of a harbor freight Yukon 30x16 tool cart i got on clearance, left over material and scraps. Full disclosure, the down draft suction force is pretty underwhelming (totally expected) compared to an industrial one but it does work and utilizes an old attic fan I had laying around for years:grinning:. Next to come is a vice mount, electromagnet hold down for small ferrous parts and maybe lights!

Grab an old HVAC duct fan from an ac shop out of an old unit. Wont cost much if anything and it will move some serious volume.

Are they magnets on the end? What weight can they handle ?

Can I ask where you got the magnets? That is a nice materials mover

This is what i ordered.

Awsome! I have one ordered to put on an engine hoist. Does the magnet pull the slats up at all while positioning the sheet?

Nice build man! I gotta admit, i just about threw my back out trying to load a 4x8 sheet of 1/8 steel by myself on my pro a while back and this is definitely better.

I have not had any problems with that. Since the slats are vertical, not to much for it to grab.

Yeah, i did the same thing. Not fun especially being 50. So we decided to build this. Works great. i have a 3rd magnet so if i need to lift half sheets, we take the 2 mag bar off and just slip on the single.

Killer project! Did you happen to share those drawer bracket files? Very nice idea and clean. Thanks