While cutting 18ga with fine tip consumables my table started acting up. It will make the first cut but the torch will not fire after it moves to the next cut. The torch moves, touches the metal, raises but wont fire. The distance from the tip to the metal after it stops working is .06

Hypertherm 45xp

fine tip

torch to work .06

pierce delay .2

cut speed 150

40 amps

You need to lengthen your pierce delay. Fire Control extends the length of the first pierce, that is why your first cut is working. I would try using 0.5. I will let a Hypertherm user chime in an verify what works for them.

Ill give it a try. i was on the phone with a Ligmuire tech over an hour, he sent me a test Tap file and it did the same thing

5PD didnt help

I would check your consumable pack. I’ve had the spring on an electrode brake and give me a symptom similar.

What is air pressure settings?

I was going to lead with that but I’m getting so tired of throwing it out there as a suggestion…

You should know by now everyone’s air system is perfect.

Normally, if the delay is to short, you will get a FireControl error “torch moved before voltage sensed.” Since you did not get that error with this failure to fire, I would say Tin and Richard are very close to your answer: air pressure insufficient or firing mechanism compromised.

But, it is likely you will start getting the error I described, if you keep your pierce delay so low. Most recommend adding 0.3 to 0.5 seconds to the published pierce delay.

Also, check careful that your consumable stack is organized in the correct order and alignment. I did this be accident and had a very discouraging time tracking down the issue.

replaced them with brand new> appreciate the feedback

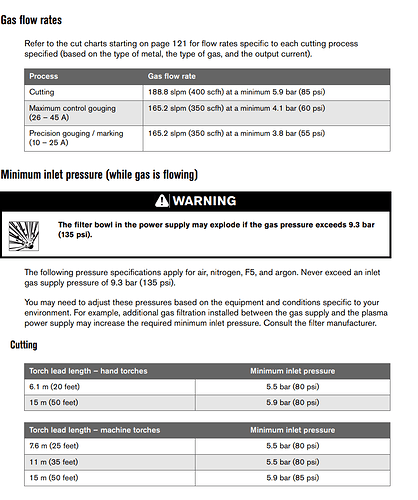

65 psi at the cutter

Air pressure may be my problem. Cameron from tech was a big help spending about an hour with me on the phone, he showed me what to do and how to set the psi. I don’t think my pierce delay is my problem because after the first cut the torch moves into the second position but won’t fire. I replaced the consumables, inspected the spring action and was careful to stack all correctly. I’ll go over my notes and try it again with fresh eyes tomorrow. Thanks for the input

Hypertherm requires a much higher air pressure to the machine. I believe they recommend at least 90 psi and the machine regulates the pressure to torch.

FireControl s first pierce always have a longer delay then what is programmed. So weather your pierce delay is .1 seconds or .5 seconds the first pierce will fire for the same length of time.

The 45xp manual is very clear about the minimum PSI required for cutting.

I feed both my PowerMax 85 and 45xp 120psi

Are they OEM? Are you matching the fine cut nozzle to the correct swirl ring and deflector or shield?

65 psi is way too low from compressor to plasma cutter air supply inlet. As Tin stated, up it to 120 psi, I run mine at 120 psi as well never a misfire with over 500 hours on my XR .

I will agree with Tin and Richard’s air pressure recommendation at the inlet. I am never less than 95 psi.

Keep in mind, Hypertherm regulates the AIR pressure internally based on the cutting demand so it is not sending the full inlet psi to the torch. But as Tin’s chart notes, it may need and will send a good 85 psi if it has it available.

yes, all Hypertherm consumables. I’m only having trouble with 18ga, it cuts 14ga easily and cleanly with fine tip consumables

I have 150 psi at the plasma cutter showed it was cutting at 65 psi

Well this is a very valuable piece of information.

It leads me to believe if you can swap back and forth between 14 gauge and 18 gauge and it doesn’t work on the 18 gauge it’s probably your cutting parameters.

Did the file that was failing ever get posted?

Seems super slow for 18 gauge at 40 amps. Especially for a hypertherm.

Those are book specs.