I have had my machine for a few months now and have been able to play around with it a few times. The first cut I made was usable and seemed okay. I was actually really impressed. I downloaded a file from an Etsy and cut out a collapsible fire pit and I noticed that I was having cut issues. A slot I designed on each side of the cut was around 1/4" and when the cut finished one side was 1/8" and the other on the complete opposite was over 1/4". Today I did some test cuts to check what ipm i should use on 16ga and it seemed that 80ipm was right on. So I attempted a bigger cut and it turned out horrible. Before cutting I checked all of my lead screws, made sure I had perfect alignment on the x axis and also on the y. Nothing needing adustments. My question is I keep using Autodesk Fusion 360 to design the piece and also to create the G-code. Could it be an issue with the code? I mean this piece looks horrible. Some lines dont even match up. Any help would be appreciated.

If you could post a f3d file that it would let us look at the tool paths.

It looks like you’re cutting on the wrong side of the line in a few places.

And all the slots would have to be designed or allowed for to be larger because of the natural taper in plasma cutting.

But a quarter inch to an eighth is a parameter, consumable, or air problem.

Also which plasma cutter are you using with which consumable set.

When I created the file I made certain the arrow was on the inside of every cut for anything interior and outside for the overall cut.

I have the RazorWeld Cut 45 with the consumables that came with it. I bought the whole package from Langmuir.

And when i made the slots in the other project I made the slots 1/4" for 3/16" plate.

i checked the f3d and you selected your inside contours properly.

check for motor coupler slippage and or a lose motor port plug.

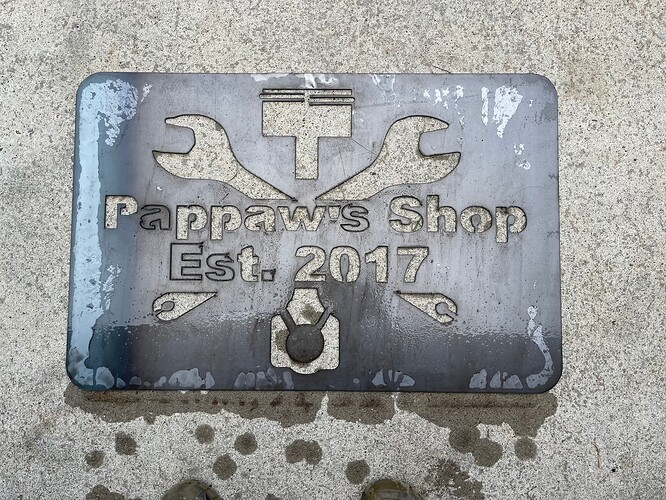

I ran some test runs and believe some of my problem was my torch lead was rubbing my left x screw at the motor coupler. Then I found one of my bearing roller assemblies was loose. Never thought to check the obvious things. My second cut was not 100 percent but much better.