Hi there

You Crossfire veterans out there have probably heard this question a few times, I’ve been through the forum looking for discussions on best air system set ups and it appears in many cases it may be dependent on climate, location etc. I live in a hot humid environment, not far from the Great Barrier Reef, and am having a bit of trouble with consumables and cut quality while finally getting the Pro set up and running. Anyone out there in a similar climate been through this? Should I be keeping the Motor Guard filter and add a dryer or will something like the below do the job? The below set up is probably on the cheaper side of things but I could upgrade.

Following on, as you can see, there is a lot of pressure on the filter. Is this normal with about 100psi coming from the compressor? Or are they designed to do this when the filter housing is tightened?

Motorguard filters compress quite a bit when installed. That looks similar to mine, after they have been installed.

The linked air system will work, but the desiccant filter is very small and will require changing the beads often.

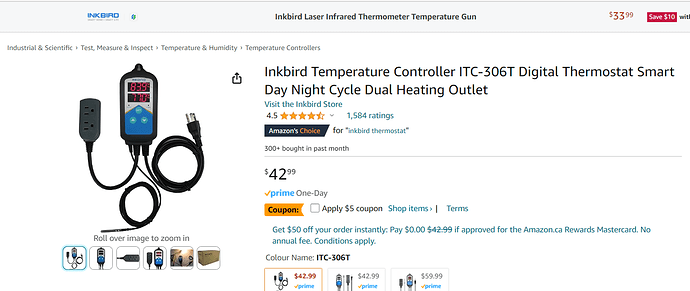

I use this 1 quart desiccant dryer in my air system and it works quite well. Amazon.com

yes they are, Motor Guard should be the last filter before your cutter.

That would be a bare minimum.

I would make sure you have a tank drain to start with on the compressor, and make sure it gets opened long enough and often enough to get the water out.

Then research refrigerated driers and see if you might need one of those.

you can also do a search in the top right for “dry air” and you will see lots of other ways to get the job done.

you also want a desiccant filter of a decent size, again you can search what other people are using and see what avaible.

Make sure your compressor is not in a box or shed exposed to very high temps.

The more you search this Forum and others you will start to get a idea of what might work for you.

Ok, good to know. Thanks

I live in Ottawa Canada…and the temps and humidity are horrible here…until winter…then it is freaking cold…but here is a bideo of my air drying ststem…works great for me…get close to 1500 pierces with all this… https://youtu.be/Xjr-SezAxcI?si=auLMDfafDh5h0HkJ

Great set up there. I have some work to do, I won’t need that number of piercings but I will need quality cuts. I took a lot away from that video, thank you.

pierces are the hardest on consumables…I also get around 3hrs of torch time with this setup…

if you get low pierces then yoiu will also get low cut quality as it means you are having moisture in your air.

micron air filters (motorguard and similar units) are best used at the end of the system so they do not get saturated with moisture and then reduce air flow.

can you post picturs of your air setup?..it might help see if you have anything really visable with it.

also poor cut quality has a lot to do with actual torch height …have you ever measured the actual torch height?

My air set up is not adequate so I dont want to embarass myself by sending a picture just yet. I only have the motor guard type filter set up. I have a 3hp 18cfm, 125 PSI, compressor with 100 litre tank, there is another 100 litre tank nearby cheap and I am going to try and pick that up today to add to the unit. I am trying to do this on a realistic budget for wanting to cut a small number of mostly brackets and small fonts for light aluminium and steel fabrication as a small hobby business selling pickup racks, pickup bed fit outs for camping and trades and other small projects . The best I can do with 15amps, which is the power I have available (standard for Australian residential), is around 3hp motor which seems to be adequate but it does look like I need more air. I will try and avoid a refrigerated unit for now, I am getting some decent airflow in my shop even when it is warm.

At this stage I will trial the following air flow process;

AIR COMP PISTONS > AFTERCOOLER > WATER SEPERATOR > TANK > DRYER

Hopefully I can still achieve 80 psi at the plasma.

I am using cut heights from charts and entering to the post process and still working on finding the right heights for different materials and thickness. Everything is working okay, but the cut quality needs to greatly improve.

Thanks for taking an interest, please put forward any advice.

Never feel embarassed about any system you have…we all started somewhere…and even the smallest change can make a worls of difference…let us help…no one will ridicule or shame your system…

ok…so my system seems like overkill…but it was all bought second hand and is salvaged parts…from what you describe you biggest issue is the size of your tank and the motorguard filter…

the 100 litre compressor and tank is way too small…it will run hot and wet…but you can make it work…

so in order to get the volume of air you need to run a plasma you need to keep your lines as large as possible…so using 3/4" PEX or equivelant size pipe is important.

next…going from the 1st compressor and tank to an after cooler is good…put an auto drain in the first tank or drain it every few hours of use…

after the aftercooler to water seperators is great…

a refrigerated dryer would be great next…but if not then go with the tank you suggested.

after the last tank you will need desiccant beaded dryer to monitor your moisture in the air…and at the end the motorguard filter…then to the plasma…

as long as you maintain large pipe sizes and remove reduced fitting and hoses you should be able to maintain the air you need…

Thanks toolboy, gotta start somewhere. I’ll keep the lines as large as I can and I have identified some smaller lines on the unit now. Thanks for the input again, appreciated.

Your after cooler and water separator will do just as good after your tank and not put unnecessary and need pressure on your pump. That can make your pump fail.

You will get there I did one piece at a time too

Thanks Phillip. I will have a look at my configuration and if that works. I was also looking at setting up a small fan behind the aftercooler which may work better after the tank.

That is my set up. There is a thread on here which had some long discussions about that in particular. In it I actually had on between the pump and tank. That is until I started VA bunch of testing. It is kinda a long thread though.

I have saved this, some good information here to absorb. Hopefully i can track down the same parts in Australia, i am sure i can. I will have a good look at putting the aftercooler after the tank which may be good on hotter days. As i understand there is a cooling benefit with the second tank also.

Once again, I find myself in total agreement with @toolboy. No reason to feel embarrassed.

I found one of my best moisture management things that I could do is to make sure I regularly drain the tank. And my friend, Glen (toolboy), gave a great tip of putting termperature sensing to electrical switch on the compressor and that drives my electronic device that automatically drains the tank. Now every time the compressor runs, the drain opens for 0.5 seconds. It is relatively inexpensive and your tank is ‘designed’ to have condensation form inside.

Well…not 100% sure that the tank was ‘designed’ to form condensation ![]() but if you think that way, then you can take advantage of this side-effect of the tank.

but if you think that way, then you can take advantage of this side-effect of the tank.

again I am thanksing @ChelanJim for thanking me…lol…

believe it or not tanks were designed to form condensation…thus the shape and drain at the bottom…

then temperature sensing swith is a thermostat control available on Amazon…

Ink bird make a whole bunch or cool things like this…

I use one to turn my cooling fan on and off…and wil soon incorporate one into my heated floor system.

Hi ChelanJim

I have been running small flexible hoses coming off a compressor that is not adequate. And I only have the motor guard filter attached! Yesterday I found another tank for my compressor so I now have 50 gallons and I am now well informed of what a realistic system for my set up will look like. I will certainly have a look at a sensor and drain, hopefully available in Australia. This will be a good idea considering the variation I will have in temps and humidity. Thanks for the input.

If you want to read a touch more about how/why I hooked up my automatic drain the way I did, here is a post:

My 74 year old next door neighbor restores old cars and trucks as a hobby and source of income. He has a 2 bay unattached garage with one setup as a paint booth. His work is beautiful and clients are lined up waiting for their turn. He frequently uses a plasma cutter, has a CNC table, and paint guns. I was talking with him last week about his system. He uses a 5 gallon plastic bucket filled with plain water and coils 10’ of air hose up in it. He uses a cheap HF 2 bulb filter setup as the hose exits the bucket. He never has moisture problems with his paint guns or plasma cutters since he switched to this setup years ago. I wish I had talked to him before investing hundreds of dollars on filters…