No they didn’t, so I reached out to Dustin @ Primeweld yesterday when I saw your post and asked him what was going on. He said they’ve been focusing on trying to perfect the smaller tables, and hadn’t pushed forward with making the larger table yet, but that when they do, they still plan to send me one to review.

So, as @Kwikfab noted, these are a bargain-priced table, and you get what you pay for.

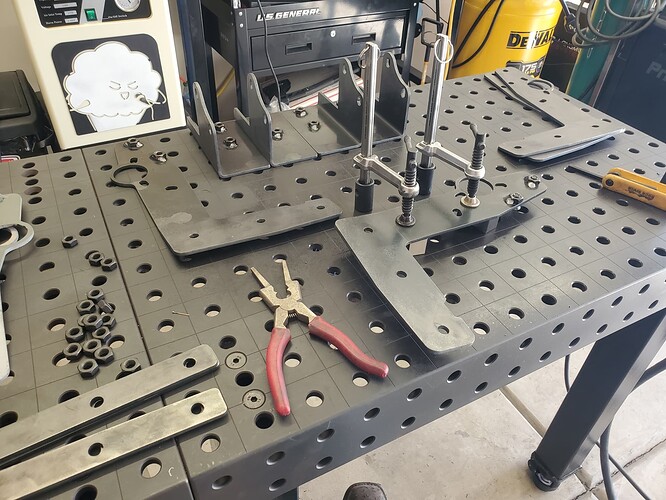

I will say that the tables I received have worked well enough for most of what I’ve thrown at them, but they are pretty flexy, so you can’t anchor something to the middle of one table, and weld a bunch of stuff to it and expect it to be within 0.030” of flat when you’re done (probably not even within a 1/16”, honestly). I had a guy who welds stainless turbo manifolds on these tables tell me his flanges don’t end up within a 1/16” of flat, and that it’s never been an issue because they suck up to the cylinder head just fine. That didn’t strike me as correct, and I think most people doing that kind of work use an old cylinder head for fixturing, but that was one thing I heard that put the accuracy of these tables into perspective. When do you actually need to be flatter than 1/16” on a weldment!?

I will say that in most cases, the table surface seems to suck up to my work, “flatter” than the dip they have at rest. And if I’m working on something large, and can go across my pair of tables, capturing four edges, in addition to the two surfaces, things seem to come out pretty darn straight.

Another thing I will say is that I do really like the nitride coating on these tables. Yes, I’ve slipped a couple times with my grinder, and it comes right off, but it holds up amazingly well to weld spatter and general working wear. With the exception of the three places I’ve touched the tables with a grinder, they still look brand new after a wipe down.