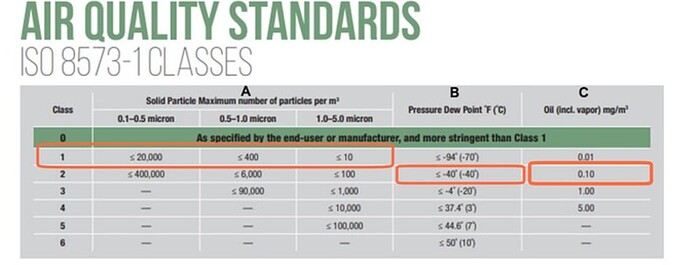

Fun fact if you are drawing air from an environment that’s -60° Celsius atmospheric pressure you will achieve the desired -40 Celsius pressure dew point at 100 lb pressure with no added air drying equipment.

The average mean temperature at the South Pole is my - 60° c making Antarctica the world’s biggest desert. And it’s a desert because of the cold the same reason we chill air to get rid of water vapor in our systems.