@Bradfab , Toolboy was, of course, talking about the Club of the Confused, of which he is the founding Chairman, President, and acknowledged expert. ![]()

The file opened up fine for me in Fusion 360. Everything looked smooth. But then I extruded that DXF and started a new sketch and projected it to it and resaved it and I believe that fixed the overlap. @TomWS can confirm

That circle you cut out too would have been the off cut.lead ins suggest that it would have been cutting the wrong direction. so what does the metal look like you cut the circle out of? That would be truly the finished edge.

Have you inspected or replaced your swirl ring. It feels like the chatters may be coming from the airstream somehow?

maybe i should switch the direction of the cut for the small letters? how would i get overlapping lines? i want to prevent this problem in the future. tomorrow i am going to do test cuts on several fonts using fusion 360. Is sheetcam more friendly on the letters? never used it before. I can navigate my way through fusion very well. I will recut the dxf file that you cleaned up and see if that helped. I find myself selling more product these days with personalization so i need to get this letter cutting issue resolved.

Swirl ring is clean, i can see through each hole and i have it in the right direction . circle cut looks very clean on the other end.

Glad its working out.

I do not know Fusion…I use sheetcam…but if you look at posts by Tinwhisperer you will find all kinds of videos…tutorials by him

maybe install a pressure larger faced analog pressure gauge here and see if the needle is fluttering during the cut. setup a 48" straight cut so you have some time to watch.

I know there is a gauge on the plasma but that is after the internal regulator and it is quite small for seeing needle flutter.

It will also give you a idea of your total system pressure drop.

What is the output set two on of these two regulators?

I removed the regulator on the desiccant to help with flow. 125 psi on the regulator coming off tank

If by chance air flow is part of your problem. Everything we do to dry air adds air flow restriction. There have been several of us add dry air tanks to help with that.

If this was an air issue then why is every cut good now except for smaller letters?

We’re getting too far into the weeds here with the air discussion. Air quality may be causing the poor consumable life, but I don’t think it has anything to do with your issue with the letters.

I imported your original file into Sheetcam and the only design issue I see is a very short open line near the bottom of the “D”. The letters are quite small and Sheetcam had some difficulty fitting my .2" lead in on them. It fit, but the pierce hole would definitely show on the opposite side of the letter.

May not be a air issue at all. Have you tried a different font? I have a idea how tall are your letters? It will be tonight or maybe someone else can now. We could do a small project with a few letter cam it out in sheetcam and in fusion then you can try to cut it as well.

I absolutely agree. Air setup is good. Enough on the air lol. I did notice that small line which did not get cut out. But I rarely use a lead in that long. I’ve had decent results with lead ins as low as .07 for the small stuff, but then again here i am with problems cutting out small letters. I have not seen anyone in this forum yet cut out smaller letters with RW45. Maybe I just haven’t come across them. I ordered the powermax 45xp and the fine cut consumables. Really curious on the difference that will make.

I think I have some at home that I cut with my rw. I will grab a picture tonight.

Edit:

I have my laptop but no pictures here I will get a picture though. I have letters I cut with the rw 45. That are .44 ish tall

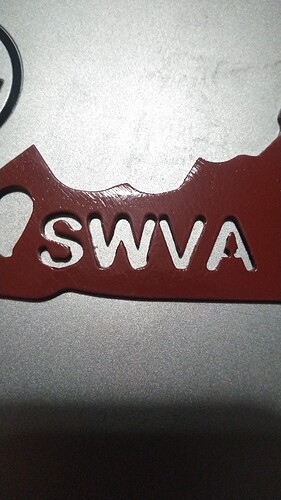

Huge improvement here with absolutely no change to settings. That would make this machine bipolar. I chose the 5 most used fonts I use. I noticed on the smaller letters they are not as smooth This setup makes cleaner cuts on letters over 1”. All 5 fonts have the same results. This was at .07 lead in btw

Looks clean. I might try to cut that earlier font on my machine this weekend see if it has any chatter effect.

Looks like you have bearings out of adjustment to tight /lose will cause chatter binding? Air will cause jagged cuts as well if air flow out of torch is disrupted by blockage from debris or damaged consumables as well.

all of those have been checked

@BradFab here is some small letters I had cut a year or so back with my rw45. These letters are .440 high. You can see a little if the piercing I couldn’t get much of a lead in.

@BradFab hello, i had a problem that this reminds me of slightly on an xr last month. it was intermittent for a couple days but finally became enough of an issue that i could find it. the connection between the motor and lead screw had separated. the only clue i had until it failed completely was poor cut quality on very small circles and needing to slow machine way down on corners. something i noticed while this issue was evolving was that when traversing the full distance of the table when getting to extreme end of the table the gantry would not hit the stops at the exact same time. One side of the table would get just barely ahead of the other side that really could only be seen in the cut upon quick direction changes on very small detailed geometry. I saw that you said your couplers are marked and you see no signs of slipping. I am wondering if either the left or right side has too much friction for whatever reason or if you have a intermittent connection to a drive motor. on a side note I use an Everlast 50 amp cutter and cut at 140 ipm on 16 gauge at 30 amps and program 56 volts for my nominal thc voltage. cutting at 78 ipm with my machine would put way too much heat into the material and give a really crappy cut edge and terrible dross.

Well I definitely keep having the THC problem again. It never wants to keep a correct cutting height no matter what. I’ve turned smart voltage off and entered several different nominal setting. I set the post process to have a variety of different heights in order to get the correct height. I just put a brand new 30amp nozzle and new electrode on and this is what I got after cutting 3 little letters