If you get a lot of dross start speeding it up. Stupid question but are you clamping the work lead to the sheet?

I get it.

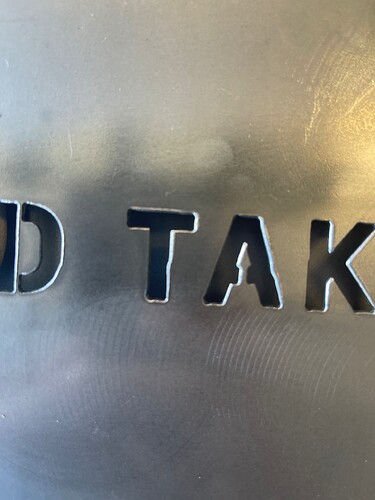

Lets get a good cut and then start tweaking. I think you are moving to fast and not piercing correctly.

Go a little faster. Like 88 ipm if 80 is what you used.

you can reduce the dross the faster you go. To a point. It also looks like you have a loose coupler.

Are you at 30 amps? Just cut out a circle and see how it comes out . A little slower if you are at 30. If a coupler is loose it will show its face on a circle. Next question ? where did you create this file?

I use fusion 360. Cutting at 30amps

cut out a circle and slow it down to 78ipm

This plasma cutter should be cutting 16ga much faster. Do you have an amp meter you could put on the leads to the plasma cutter plug. I wondering if you are getting a large voltage drop when its cutting ![]()

I’m heading out to go home in a couple. I’ll check back with you when I get home.

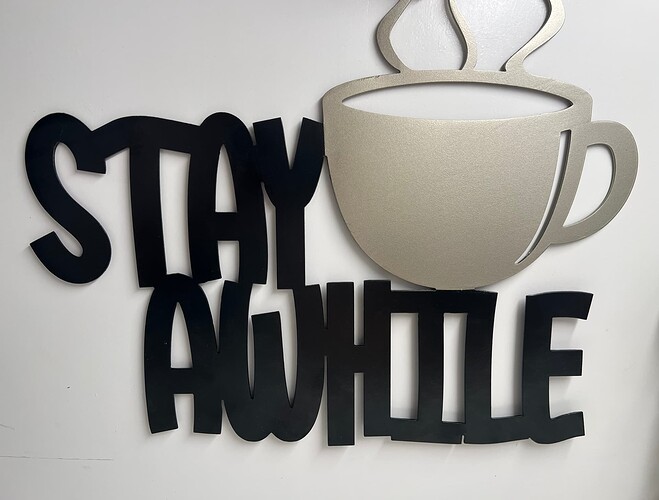

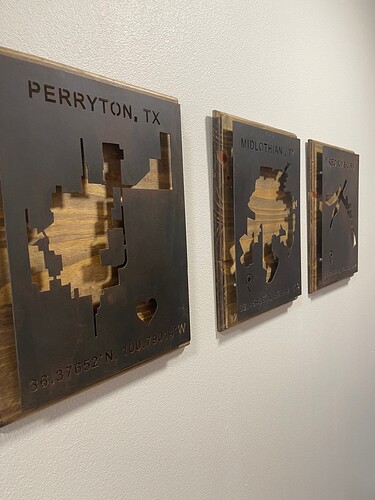

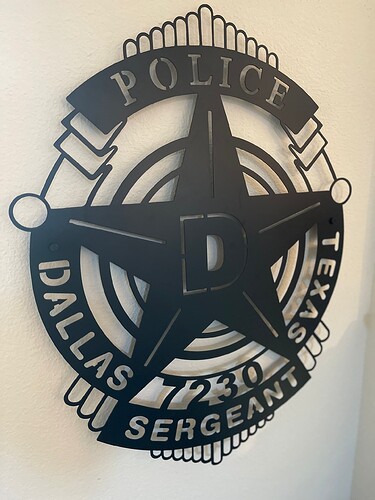

I will do the circle cut tomorrow. Headed to my day job. I am pulling the trigger on a Powermax 45xp. Not that it will cure all my problems but I do believe it will help. The fine cut consumables produce excellent cuts. I started this not knowing I would sell as many items as I do now. Im turning customers away or putting them on ridiculous wait lists just to keep troubleshooting. Im losing money at this point and need to minimize any additional problems. I did say minimize meaning I realize this still takes work and patience. With the amount of work I’m doing a hypertherm is needed. Just my opinion.

Nothing wrong with razorweld 45

Sure. Just takes lots of work dialing it in every time something goes wrong.

Hey Bradley…

Looks like the picture of the test lines is getting attention…like they say…a picture is worth a thousand cuts…lol

Circle test was perfect. I’m positive I don’t have any loose couplings. They are all marked. Just replaced one recently.

I did another cut and I noticed that every uneven straight cut is right where the lead in is. Also in a few other areas. I can get good cuts on everything except letters. Frustrating